PMM’s diagnostic dynamo Ben Johnson breaks out the Pearl Jam tapes and indulges in a gleaming BMW 635 in its twilight years.

As I dramatically skidded into the Schmiedmann car park last month, battling the elements like a gladiator in an automotive arena, little did I anticipate the spectacle that awaited me. In a sea of predictable BMWs, one machine dared to break the monotony—a regally defiant 1980s metallic brown classic, arrogantly staking its claim over two parking spaces.

Behold, not the mythic M635 CSI but the slightly less haughty 635 (sans M badge). It is a relic from an era when cars had character, not just cup holders. The sheer audacity of this vintage 6 series, lounging in all its 80s glory, left me more astonished than a caveman discovering fire and of course I dared to hope that the job, whatever that may be, would be given to me.

Getting started

My anticipation only grew as I circled this automotive time capsule. It may not have been the rockstar M variant, but this handsome machine had a swagger and that shark nosed front end that whispered tales of open roads, cassette tapes and questionable fashion choices. The weather may have been miserable, but that classic BMW was a beacon of automotive splendour, daring anyone to defy its aura. In that moment, the mundane car park transformed into a stage and the 635 CSI, my unwitting co-star, stole the show.

I didn’t need to wait long for the afternoon to roll around when the job card was handed to me containing a more slimmed down key than the usual chunky key-fobbed variants – clearly this meant that I had been given the chance to repair something that I had no idea about or had ever worked on before. Little did I know what sort of rollercoaster this old car would send me on.

With the determination of a conductor coaxing a symphony from an antique orchestra, my first order of business was to charm the venerable M30 engine into grumbling to life. The lazy starter, in protest, moaned like a worn-out troubadour, signalling a battery on life support – a clear consequence of the owner’s persistent attempts to kickstart the ageing heart of the machine. A tale as old as car ownership itself. To the car’s credit, she did start every time but sadly would cut out immediately. As for revving it – forget it. Not happening. So, there we had it – it starts then stops. What a mystery.

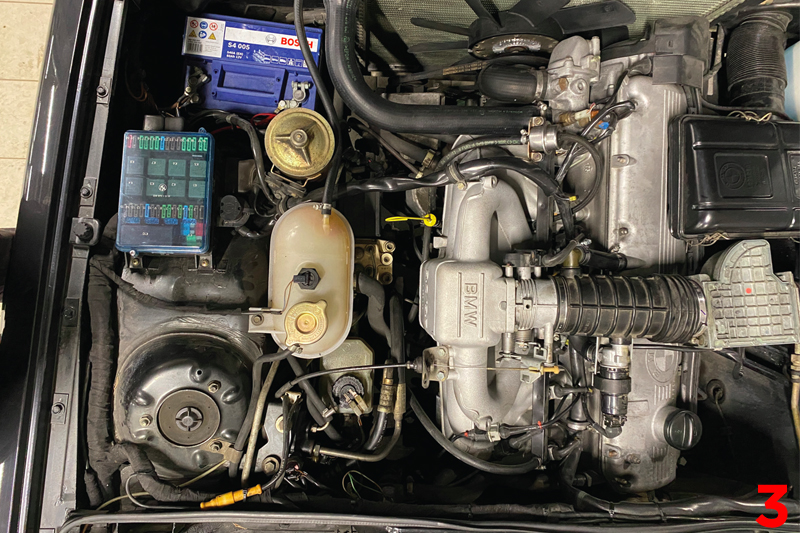

Given its vintage stature in the realm of 1985, the absence of a lambda sensor, not even a rudimentary single-wire version, was glaring. As for fault codes, well, that’s a pipe dream unless you happen to possess a Sun 2013 tester, a beast that was half of the length of the 635, weighing upwards of 200 kilos and dwarfing the vehicle it aimed to diagnose. No high-tech shortcuts here—just the cold reality that my skills, untouched for nearly 28 years since I first wielded the spanners, were about to be summoned from their mechanical slumber. Time to roll up the sleeves and embrace the challenge, for this was a dance with the vintage, a tango with the past (Fig.1).

With the car reluctantly shoved into the workshop, my comrades grumbling in a symphony of discontent, I wasted no time slapping the battery charger onto the tired veins of the vintage lady. A surge of electrical vitality was just what the old girl needed.

In the spirit of desperate optimism, I attempted the “stomp test,” a term that I loathe but, alas, fits the motley scene. Much like the missing lambda sensor, reading flash codes seemed like chasing a unicorn. Disaster! No shortcuts here—time to roll up the sleeves and let the thinking cap work its rusty magic. It was a battle of wits with this wheeled enigma.

Facing an automotive puzzle that transported me back to the days when flannel shirts were cool and grunge was all the rage – yes, the 90s – I found myself in the presence of an enigma last encountered during my college escapades in the department of motor vehicle engineering. Back then, it was an old Porsche that puzzled me; today, it’s a different vintage beast with an engine bay that’s practically a nostalgia trip.

Among the familiar yet oddly distant components, the air flow meter stood out – a curious, over-engineered contraption that hinted at the complexities lying beneath the bonnet. Memories of college days flooded back, and I pondered the potential magnitude of the task at hand. This was no ordinary job; it was a journey back in time, a plunge into the depths of mechanical intricacies.

In my mind’s eye, I envisioned myself transforming into one of those seasoned lecturers from the past – those who, with a hint of oil-stained wisdom, could sniff tailpipes and adjust mixtures to stoichiometric perfection. The ghosts of old-school techniques from my early 90s education whispered in the recesses of my memory. Uncertain if I could summon those lessons, I decided it was time to channel my inner vintage mechanic and give it a nostalgic go.

Upon diving into the heart of the matter, my first gaze fell upon the fuel pressure, seemingly holding steady at 3 bar. Yet, the real revelation came when, armed with plastic hose clamp pliers and the indispensable assistance of a colleague, I clamped down on the return line from the pressure regulator on the injector rail. Lo and behold, the idle perked up, but alas, the throttle response remained anaemic, as if it had taken a vow of non-existence.

These engines, usually content with a cozy 3-bar fuel pressure, decided to throw a classic tantrum, bleeding off occasionally to a lacklustre 2 bar. Sensing the need for a sage move, I opted for the surgical replacement of the fuel pressure regulator, swapping in a Pierburg type. A decision that paid dividends, for post-transplant, the old girl grudgingly settled into an idle. Yet, the spectre of troublesome idling and a throttle response on life support lingered, as persistent as an unwanted guest. The mechanical saga continued.

In the uproarious symphony of our workshop, an hour into the relentless quest for engine enlightenment, I nearly overlooked the subtle yet grating hiss of unwanted air. While feverishly toying with the throttle cable and the engine armed with the freshly sourced fuel pressure regulator, my ears finally tuned into the disconcerting sound.

In the quirky realm of these cars, air flow meters display a chameleon-like flexibility, working contentedly in either orientation— aluminium side up or the more conventional plastic-side-up arrangement. Imagine my disbelief when, probing beneath where I assumed an aluminium base should be, my hand encountered nothing but the exposed inner machinations of the mechanical air flow flap. The bottom of the air flow meter had vanished without a trace! (Fig.4).

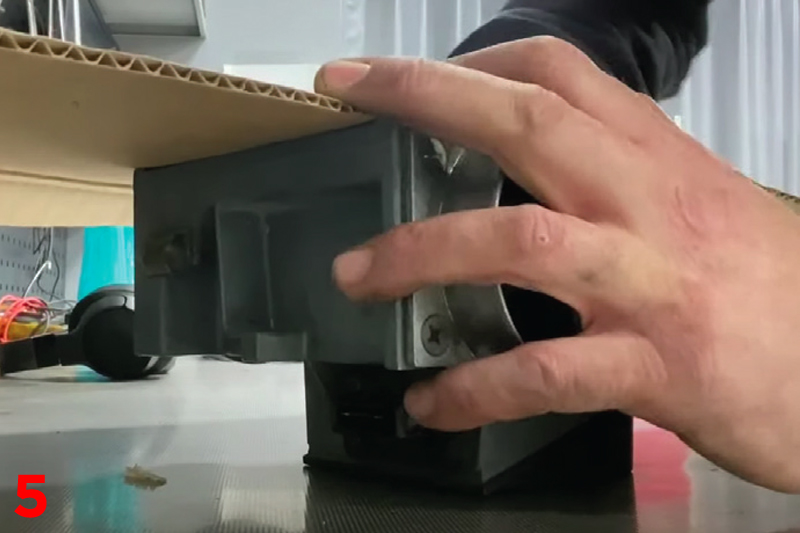

Despite a thorough search in the engine bay’s deepest recesses yielding nothing, I took matters into my own hands. Crafting a makeshift base for the airflow meter from laminated cardboard, generously coated with silicone glue, seemed like a dubious yet necessary endeavour. Installing this jerryrigged contraption, I was met with astonishment as the engine now revved with newfound gusto! However, the celebration was short-lived, for the emissions declared war on decency. Running richer than a top fuel dragster and idling more chaotically than a cammed café racer, the raw fuel spewing from the tailpipe transformed our workshop into a symphony of combustion chaos. The saga continued, now with a touch of cardboard ingenuity (Fig.5).

Having crafted a rather nifty new bottom panel for our sorry-looking airflow meter, I was delighted as the engine roared to life. Yet, the spectre of a dismal idle still haunted the proceedings. Upon yanking out the airflow meter once more, I discovered the culprit—a flap scraping against the casing. With time breathing down our necks, the decision was swift: source a used unit.

A week later, the used arrival looked more like a relic from a vehicular graveyard than a saviour. Undaunted, I slapped it on, and the car begrudgingly sputtered to life, still drowning in an excess of richness. In my quest to unravel the mysteries of emissions on this vintage beauty, an online archive safari ensued. Jackpot! A document from the ‘80s revealed that the “new” air flow meter CO adjustment screw had been cranked clockwise, settling at the richest mixture setting possible. A few, three to be precise, anticlockwise turns and we found ourselves in the middle position. Now, it was a dance of fine-tuning until stoichiometric bliss. But lacking a fancy emissions tester, my nose became the reluctant judge and the car still exuded the pungent aroma of unburnt fuel.

Removing the oil cap on this engine, if it was running perfectly would make it run lean and it would start to hunt. Removing the oil cap on this engine actually made it run perfectly – a tell-tale sign that it was indeed running super rich. Removing the oil cap (Fig.6) had allowed enough post air flow meter air to make the mixture closer to stoichiometric.

Undeterred, I pulled out the airflow meter once more, realising the flap was so slack it hardly bothered to return. Armed with ancient wisdom from online archives, I tightened the spring tension on the elusive dial inside the air flow meter. The results were pure magic— super-smooth idle, and the noxious cloud of raw petrol at the rear dissipated into the ether. Overjoyed and over the moon, I revelled in the triumph of employing old-school techniques that worked like an absolute charm! (Fig.7).

With the old girl now idling like a beauty and the exhaust less likely to upset a climate activist it was time to hand her back to the owner. Sadly, the car came on a trailer with summer tyres on so the usual post-repair road-test would be out of the question. I have to say that I will really miss this wonderful car with its quirky character and fine leather interior (Fig.8). It was testament to a bygone era that we will never see again and that fills me with a tinge of sadness. However, next spring I will service her after a deep winter’s slumber so I may finally get the chance to take her on that elusive test-drive after all.