Modern timing chain kits are far more sophisticated than the ones used a few years ago, using powder metal gears, high velocity chains and thermos-plastic tensioners (housing). They’re subjected to far greater loads, whilst weighing much less.

For any engine to operate correctly, it must use the correct grade of oil as modern oils are very complex structures which are critical to an engine’s performance and long life. This is particularly important when the valve timing is chain driven.

The dangers

Replacing the old oil with an incorrect grade will most certainly cause failure. A timing chain relies on two things to keep working. The first is lubrication, so that the metal parts don’t make contact (at a molecular level) – preventing seizure.

The second is tension, which in a modern engine is produced 99% of the time by a hydraulic tensioner applying pressure directly, or via a tensioner rail onto one or more contact points on the chain.

If this pressure is lost or reduced in any way, the chain will start to oscillate, creating fatigue in each metal link and pin of the chain, which will eventually cause the chain to break in one or more places. Before this stage, it’s likely that you will get the customer back complaining of a rattling chain.

It is vital that the tensioner gets the correct volume and oil pressure from the engine’s oil gallery. Without this, the tensioner will be unable to load the chain and failure will occur. If the engine manufacturer specified oil is not used then the tensioner will not be able to maintain the correct pressure as the engine RPM increases.

Additionally, all hydraulic tensioners receive their oil feed via an inlet port or valve, the diameters of which range from 1.5mm to 0.50mm. If there is contamination in the oil (carbon, metal swarf etc.) the feed holes can become blocked very easily, starving the tensioner, which in turn will fail to load the timing chain. It is also important to change the oil filter so that any contamination is not carried over into the new, clean oil.

Clean is critical

To enable today’s chain kit to survive it must be fitted to a clean and uncontaminated environment. FAI also recommends that the engine lubrication system is flushed just before work is started to remove the old timing chain kit. This will remove the majority of contaminants that will have built up over the life of the engine.

During installation the sump should be removed and inspected/cleaned along with the oil pump and pick up pipe.

Grade Guide

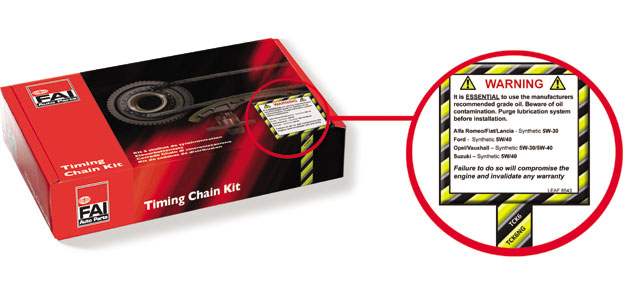

It is essential to use the manufacturers recommended grade of oil as failure to do so will compromise the engine and potentially invalidate any warranty.

In response to these challenges, FAI has rolled out a program of technical information labels (see picture above) specific to each popular timing chain kit offered in the FAI range.

The label gives the exact oil specification needed for the kit, including grade e.g. 0-30W, composition e.g. synthetic/mineral, etc. and any relevant additional important information such as “low ash” for engines using DPFs.

Alfa Romeo/Fiat/Lancia – Synthetic SAE: 5W-30

Ford – Synthetic SAE: 5W/40

Opel/Vauxhall – Synthetic SAE: 5W30/5W-40

Suzuki – Synthetic SAE: 5W/40

If you’re new to fitting timing chain kits, you can watch the FAI tutorial at www.faiauto.com