Nissens offer some possible causes for a corroded condensor and how to avoid future issues.

The condenser is placed in the front of the car and is typically attached to other heat exchangers in the engine compartment. The condenser is crucial for correct A/C system operation as it ensures that the refrigerant changes from a gas to a liquid form. This is achieved through the condensation process, where the refrigerant heat is extracted and exchanged with the ambient air.

PROBLEM

As one of the A/C components closest to the external environment, the condenser experiences extensive wear and tear during its lifetime. Climates that experience rain, snow and humidity can be rough on the condenser; as roads are covered with salt during the colder months, the saltwater will spray the exposed condenser and increase the risk of corrosion. A corroded condenser will increase the workload on other system components, especially the compressor. Many compressor claim cases reveal that a condenser with restricted efficiency was the reason for the compressor to overheat and seize.

SOLUTION

Regular visual inspection of the condenser surface can save expensive repairs. Any signs of corrosion or leaks on the condenser surface must be considered as threats for the system operation. Pay attention to the bottom part of the condenser, where tubes and fins are mostly exposed to extensive humidity and aggressive salt spraying. Oil residues on the condenser can indicate leaks and you should always replace a condenser that is leaking or has missing/deteriorated fins. When replacing condensers, choose parts with corrosion protection applied as this prolongs its lifespan considerably.

CONDENSER CORROSION – POSSIBLE ISSUES

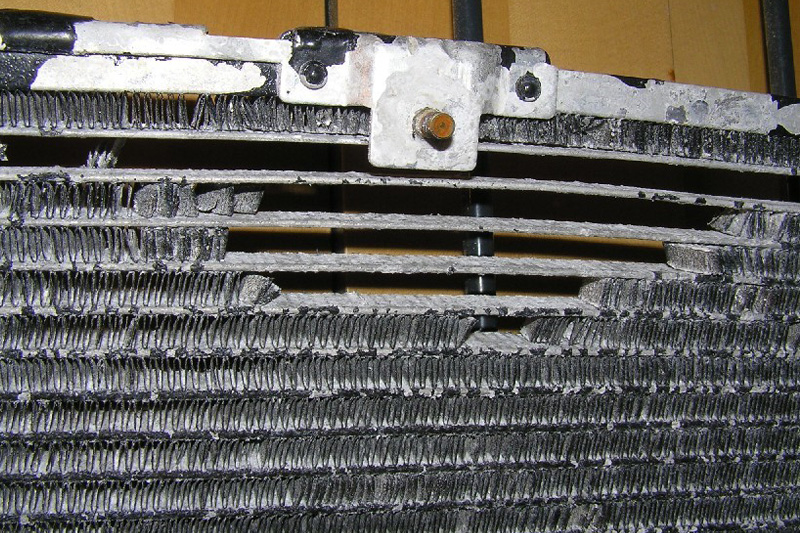

Deterioration of condenser fins

Even if the condenser doesn’t leak and seems to be tight, the heat exchange capacity may have been reduced significantly. As corrosion attaches to the thin aluminum fins, the working surface area is reduced, decreasing the overall heat exchange capacity of the condenser.

Lack of fins

As the fins corrode over time, they will fall out of the condenser. With the number of fins reduced, the condensation process then becomes significantly more ineffective, creating an increased overload on the compressor. Removal of only one fin row from the condenser can reduce its thermal performance by up to 3%!

Leaking condenser

Testing has shown that a condenser with missing fins, due to corrosion caused by saltwater, will eventually start to leak. The leakage is caused as the lack of fins destabilises the condenser construction, making it more vulnerable to wear and tear. As the refrigerant disappears, the system won’t function properly. Furthermore, as the lubricant can’t be distributed in an empty running system, the compressor will be exposed to overheating and seizure.