PMM ’s expert diagnostics troubleshooter Ben Johnson wonders whether a simple battery replacement could have saved a customer a lot of money and hassle.

A rather sorry looking X5 was dragged into the workshop recently on dollies since the owner had reported that when attempting to start the vehicle all he got was a load of warning lights and check control messages – what these car forum types call “the trifecta”.

Once safely in the wash bay, where we stash most of our, shall we say, “problem cases”, I set to work trying to figure out what had gone on. The first thing I noticed was that the ignition came on and that was about it. No head unit, no air conditioning and not much else seemed to be switching on. The first thing that was obvious was the screaming of the cooling fan on full speed which usually indicates a catastrophic failure of some kind. It reminded me of my own car – the BMW i3 that suffered from a PT-CAN failure (see last month’s issue). I felt a warm glow inside that perhaps it might only be a bad wire – wishful thinking on my part!

As with any fault find the first step is to gather evidence – this evidence was straightforward: the car had some serious electrical problems. At this stage, the PTCAN was going through my mind: Rodent damage? Hardware failure? Trying not to speculate, I plugged in the BMW proprietary ISTA diagnostic tool and got absolutely nothing. It was clear that although the ignition was coming on, Terminal 15 wasn’t.

Entering the chassis number on BMW vehicles allows the tester to communicate on K-Line in the event of a Terminal 15 failure but in this case, it was having none of it.

Obtaining the fault codes

With no way to read fault codes I had absolutely no idea what the problem might be since not knowing why there was no communication to ISTA was one thing but what was causing that was another. Plugging in Autologic showed the same results so I knew that the cause of this comms issue was a current fault with the car and not a tester issue but it’s always worth a try to test some other method of retrieving fault codes just in case one gets through.

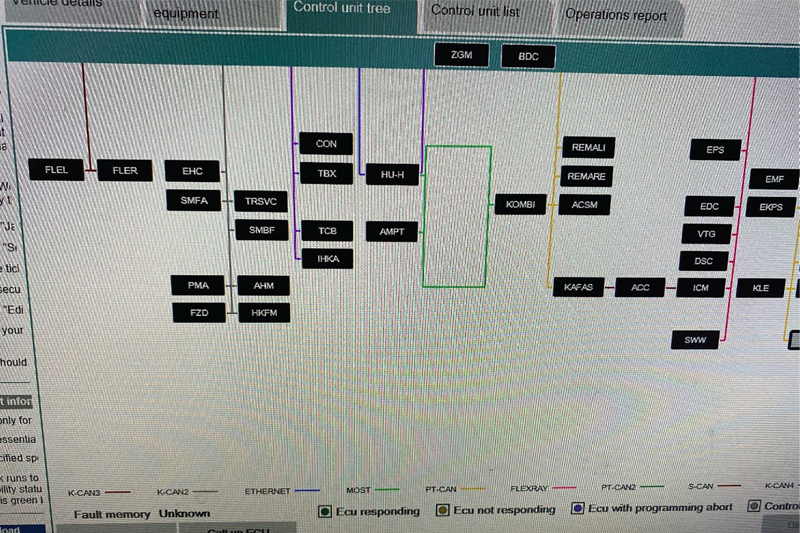

I had thought immediately that the BDC – Body Domain Controller might be faulty since this is the gateway of the vehicle and as a gateway, if it fails nothing will be able to interact. So that means no ethernet, flexray, CAN (body, chassis nor powertrain) can talk to each other. With these critical systems not functioning it isn’t surprising to see “the trifecta”.

Testing shorts to ground

The BDC houses all of the terminating resistors for the various networks, including the diagnostic socket. The BMW EOBD connector, like most cars, allows communication to the BDC via pins 6 and 14. As this is just a line direct to the BDC and not to the CAN itself, it is not suitable as a diagnostic aid to assess the condition of the CAN, whether that be K or PT-CAN since the diagnostic socket has a resistor soldered into the wiring harness close to the diagnostic socket and the other is in the BDC itself. So, the diagnostic plug has a mini “main line” to the BDC; of course, there are no branch nodes running from this wire. I tested 60 Ohms so that proved to me that the diagnostic socket and the BDC resistors were intact. I tested for shorts to ground and power and found none but I also found zero volts on the CAN high and low – a serious problem!

I climbed into the back seat and reached over to the false floor. The boot lid was inoperative owing to the electrical problems so I popped out the false floor and checked both low voltage batteries – surprisingly the main battery was being charged at 14.5 V by the DC/DC converter so the high voltage side was working normally – very strange, I thought.

One thing that made me strongly suspect that I was dealing with a BDC issue was when I decided to remove the integrated head unit high/IHKA panel. I decided to start with the one common denominator which in this case was the non-illuminating IHKA panel. I figured that If I could find no voltage on terminal 15 to this unit then I could trace it back to its source, maybe a relay or a fuse. Removing the unit is a two-minute job so it seemed easier to do that than to check the fuse. I actually found out that there is no terminal 15 at all, only a ground and one terminal 30 supply. With these confirmed as okay I changed tack and whipped off the passenger footwell trim to access the BDC. Nothing really stood out, no external relays, no external signs of anything wrong.

Time for a hard reset

With no idea what to test next to just be able to retrieve fault codes I made a decision to de-energise the high voltage system and perform a hard reset. Once I had confirmed that the DC DC converter had stopped providing charge to the low voltage battery, I removed both the positive and negative terminals, made sure no external battery support was connected and joined them together for five minutes. Luckily this handy trick did the job by discharging the capacitance of the BDC. Upon refitting the battery terminal shoes I noticed that not only had the cooling fan stopped screaming but also the forum favourite “trifecta” had disappeared.

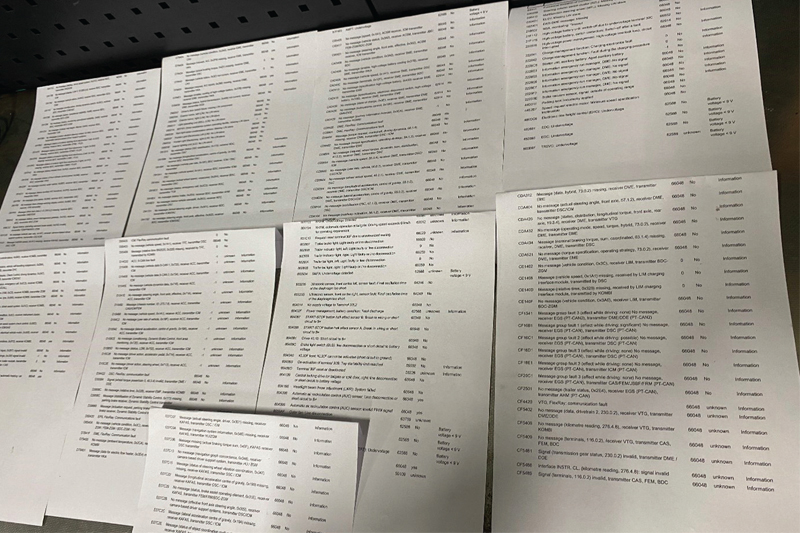

Popping off the dollies I was able to drive the car out, round the car park and back inside again. Knowing that cars don’t fix themselves I plugged in ISTA and, not surprisingly, the car communicated immediately with the tester. Once I had got into the car I printed off probably the largest number of fault codes that I have ever seen.

Printing out 8 pages of faults was not out of the ordinary when faced with a failed BDC but what perplexed me, as always, is why did it fail?

Looking on the ETK it seems that quite a few versions of the BDC have been manufactured since 2017, when this X5 was produced so I decided to order a new BDC but still I wanted to find out if there was something in this X5 that had triggered the failure. The only thing that popped out was when testing the 900 Amp CCA battery – it tested as having only 60 Amps’ charge in it. This was changed to a new battery right away. Once the new BDC came it was left to be programmed which took hours to do but seemed to eventually bring the car back to some semblance of normality.

So back to the customer the X5 went with no “trifecta” and under its own steam. Funnily enough, upon picking up the vehicle, the customer mentioned that the car had been complaining about the battery charge for some time yet they failed to bring the car to us for what may have been a simple battery change and registration. Who knows, it might have even prevented this costly BDC failure.