In the last instalment of our guide to Bosch’s KTS diagnostics software, ESI[tronic] 2.0, we looked at the maintenance and equipment tabs, this instalment it’s ADAS under the spotlight.

At this point in time, ADAS is vitally important in today’s modern-day safety systems. But they are about to get even more so – both for drivers, and for the modern-day car manufacturer. Since 2014, all new cars have had to be sold with electronic stability programs. These programs support the driver in nearly all critical driving situations, by detecting vehicle skidding movements, and actively counteracting them.

By the end of this year, it will have become an EU legal requirement to equip all new passenger cars introduced on the road with certain ADAS functionalities – which includes adaptive cruise control, emergency braking and lane assist systems. This legal obligation has already been in place since May 2022 for all new car model homologations. ADAS will no longer be reserved for high or mid-class vehicles – it will become applicable to all vehicle models on the road.

So what does this mean for workshops and garages? Well, as more vehicles are built with ADAS as standard, so more of these will start coming through the doors needing repairs. Sooner or later, every workshop will need to recalibrate ADAS. And now’s your chance to get ahead of the game.

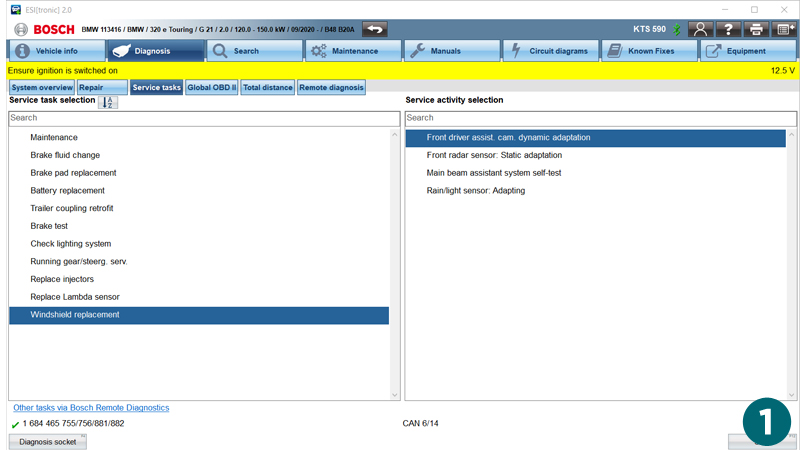

ADAS systems are mainly based on radar and camera sensors, working at the front and rear of vehicles to help keep the driver safe – from emergency brake assist at the front, to blind spot detection and parking at the rear. Even routine jobs like windscreen replacements often now require system recalibrations, due to the fact the sensor sits behind the windscreen (Fig.1).

There are a few other cases when the ADAS calibration is needed:

- After wheel alignment (the steering angle sensor will need resetting and the radar and camera recalibrating)

- After any kind of work or adjustments to the chassis, steering system or suspension (e.g. shock absorber replacement)

- After accident/body collision (even small ones count)

- In the case of non-optimal functioning (e.g. customer complaints or troubleshooting)

- After a service or repair.

This means that many workshops are in fact already facing changes to the way they work, as recalibrating sensors becomes part of the job. There are two types of calibration procedures, both of which are supported by Bosch’s technical systems:

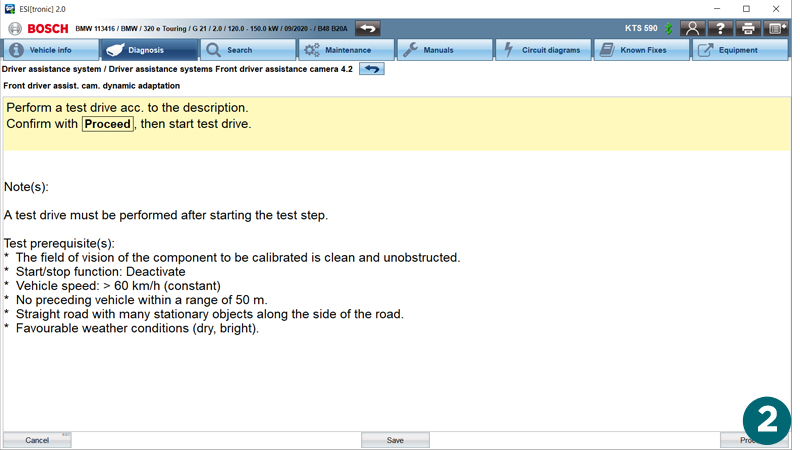

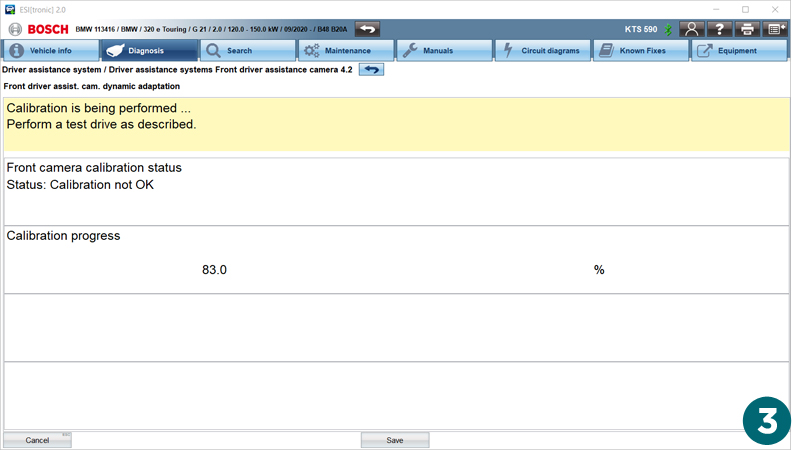

- Dynamic (drive cycle). This is done by driving the car in specific circumstances – preferably on a straight road with minimal turns, and above a certain speed. A diagnostic scan test is needed, and the test needs to be triggered with a diagnostic tool such as a KTS (Figs.2&3). Bosch equipment required: ESI[tronic] 2.0 and a KTS diagnostic device.

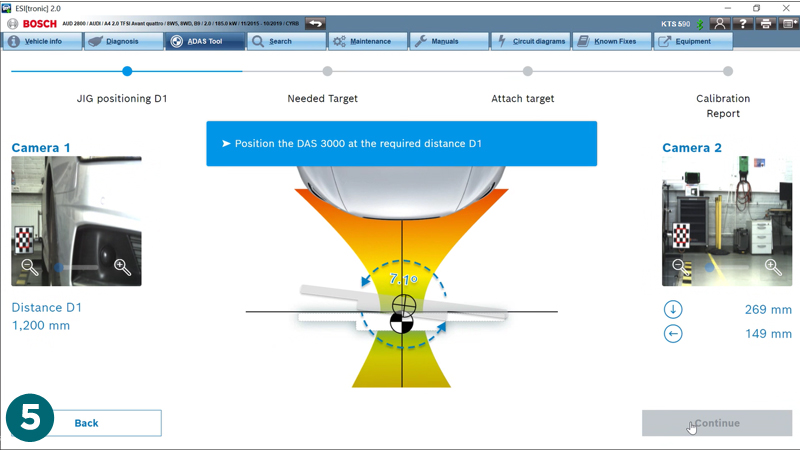

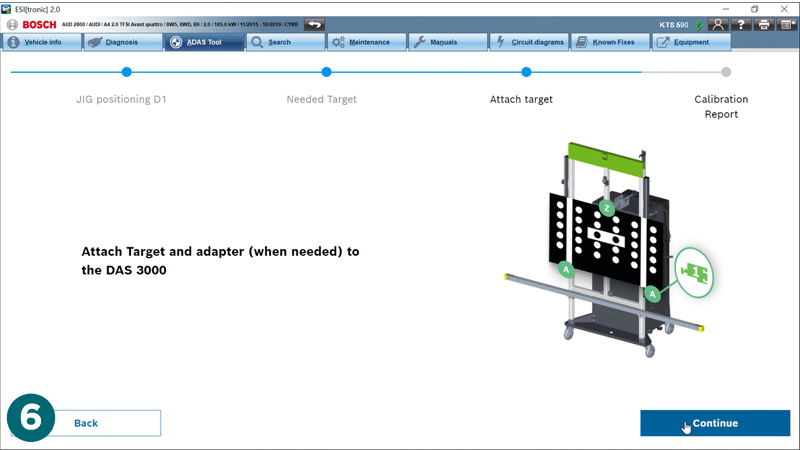

- Static: This requires specialized equipment – a static calibration tool such as the DAS 3000. A target board (for camera sensors) or mirror (for radar sensors) is used with the diagnostic tool in precise locations around the car to perform the recalibration. You must also have a flat surface (floor or lift suitable for wheel alignment) with enough free space around the car to set up the calibration tool (Figs.4,5&6). Bosch equipment required: The DAS 3000 universal calibration tool, ESI[tronic] 2.0 and a KTS diagnostic device.

It is worth noting that the type of calibration differs between car manufacturers and that a combination of static and dynamic calibrations is possible. For example, BMW uses a dynamic procedure for camera calibration and a static procedure for radar calibration, whereas VW uses static calibration.

For many cars requiring just a dynamic calibration, you only need a KTS and ESI[tronic] 2.0 to get the job done. But for at least half of the hypothetical car parc, you will also need a static calibration device such as the DAS 3000. The good news is that you’re in safe hands with the ESI[tronic] 2.0, as it gives you a clear indication about which type of calibration is needed, as well as guiding you through the procedure.

At the end of each calibration there is the option to save the report, something that’s crucial to prove your procedure is compliant with the manufacturer’s guidelines.

Self-driving future

The ADAS trend is only going to become more firmly established as the car manufactures of today begin to make the move towards a self-drive future. Bosch has been accompanying this trend from the beginning, with necessary solutions that can be tweaked and adapted over time. Both the ESI[tronic] 2.0 and DAS 3000 are future facing systems, with the software being continuously updated in line with new developments.

As one of the leading developers and suppliers of ADAS systems and components – and a market leader in ADAS research and development – the German manufacturer knows how to treat and work with these systems. Rather than offer ADAS calibration functionalities as an add-on, or make it available as part of a more expensive software package, the Bosch ESI[tronic] supports both static and dynamic ADAS calibration routines in even the starting level diagnostic package.

Next instalment we learn how the ESI[tronic] can enable you to work safely and efficiently with hybrid and electric vehicles.