FAI Auto Parts look at some timing chain tips.

The use of timing chains to synchronise engines in OE manufacturing is growing year on year.Timing chains offer higher strength values than the rubber and glass fibre cord timing belt, and as the chain is mounted within the engine, it can operate at a reduced friction level due to the engine oil coating it, keeping the chain and sprocket contact to a minimum value.

This should mean that the chain will last indefinitely if the working environment is non-hostile.Therefore, most OE manufacturers do not include replacement or even inspection of the timing chain in their service schedules.

It is for these reasons that the aftermarket is seeing a rapid growth in timing chain kit replacements. Some kits are for preventative maintenance, but most are due to catastrophic failure. Unlike chains used in the 1960s and 70s, modern chains are much longer and lighter in design.This is a conscious decision by OE manufacturers to reduce weight and increase efficiency.

In addition, extended service intervals were introduced into OE manufacturing. Whereas 15 to 20 years ago oil would be changed at 6,000 miles, most mainstream manufacturers are now quoting more than 15,000 miles. Plus, many engines are now using stop-start technology, which multiplies the stress/loads on the engine, whereas a non-stop-start engine used for commuting will only go through the average five second period of low oil pressure on start up when wear can occur.A stop-start engine may have to suffer this reduced oil pressure scenario 10 to 20 times during the same commute.

It is therefore vital to replace all associated parts as well as the chains, as it is not good engineering practice to fit a new chain to worn sprockets and guides, as the excessive clearances created by the worn parts will reduce the life of the chain. It is also vital that the tensioner is always replaced, as this component is critical for the chain to remain at the correct tension. Failing tensioners will allow chain(s) to oscillate in lateral and axial plains, initially causing excessive noise, followed by metal fatigue, extension and, eventually, total failure.

The case study above shows why FAI is focused on production quality and follows OE specification. Using premium materials like chrome pins to reduce wear from high friction loads and to extend service life when oil condition becomes hostile.

Due to the small engineering tolerances (clearances) used in modern engines, the amount of contamination needed to deem the engine oil as hostile is much lower than many people would think.Therefore, to ensure your timing chain is always operating in an optimum environment, it is important for the engine oil to be of the correct grade (as specified by the manufacturer) and, if necessary, it should be replaced along with the oil filter, even if it is not due as per the service schedule.

Case Study: Timing chain breakages in a Fiat 1.3JTD engine.

The engine has an oil service schedule of 18,000 miles and FAI has anecdotal evidence that the original chains are breaking at 30,000 miles. Following pressure from FIAT’s UK customers, FIAT released this statement.

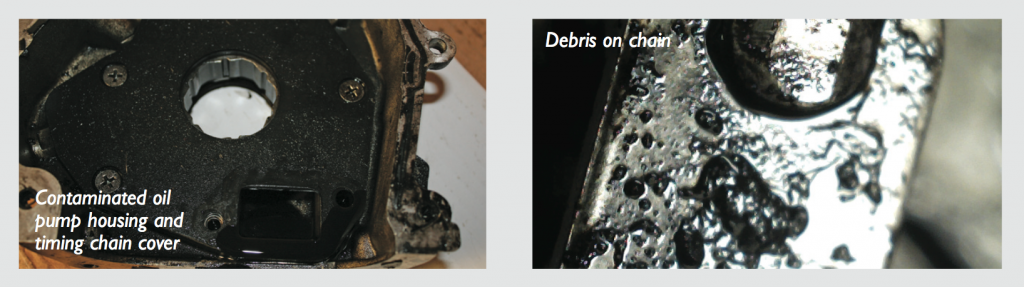

Quote from FIAT letter:“Of particular concern is that at about 70,000 miles the timing chain can break on these vehicles, causing catastrophic engine failure, which could be due to the serial contamination of the engine oil, causing excess wear to engine components”.

The cause of this was a DPF regeneration process that FIAT developed. It injected fuel on the exhaust stroke, which would act as a cleaning agent as it passed through the DPF. However, this system fails and, consequently, excess fuel is washed past the piston rings into the sump, diluting and degrading the oil.This in turn reduces the hydraulic pressure delivered to the timing chain tensioner and increases friction, allowing the chain to move out of its correct path, generating noise and eventual failure.