Allow the engine and tensioner to stabilise to the same relative ambient temperature before installing a tensioner for proper belt tension adjustment. Don’t attempt to install a cool tensioner onto a hot engine or vice versa.

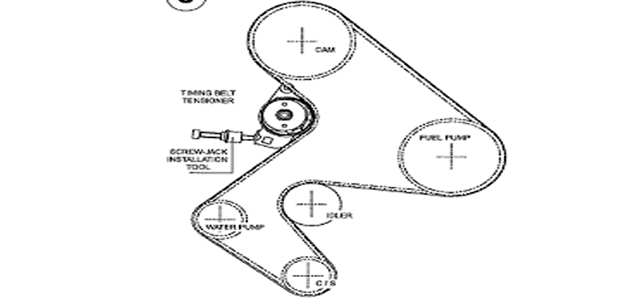

Rotate both the crankshaft and camshaft clockwise to TDC (Top Dead Centre) position (i.e. #1 cylinder firing position) and remove the timing belt. This defined position will mean there is no action (positive or negative) from the camshaft or other sprockets. You should find no sudden movement or abrupt action from either of the sprockets. Generally, cam and crankshaft sprockets have to line up with equivalent markings on the engine block to indicate TDC.

Initial set up of the TBT (Timing Belt Tensioner)

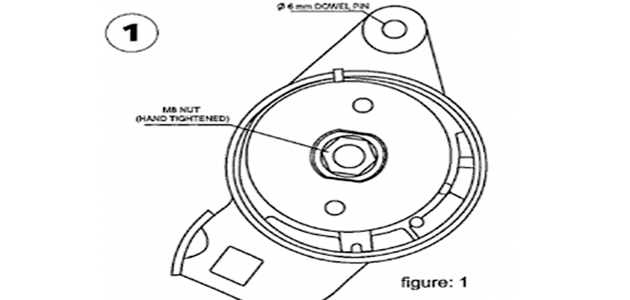

Slide the pendulum mounting bracket farthest to the left before mounting the tensioner. This will ensure that the tensioner can be mounted easily when routing the belt. Mount the tensioner while making sure that the Ø 6mm dowel pin is fully engaged (see below).

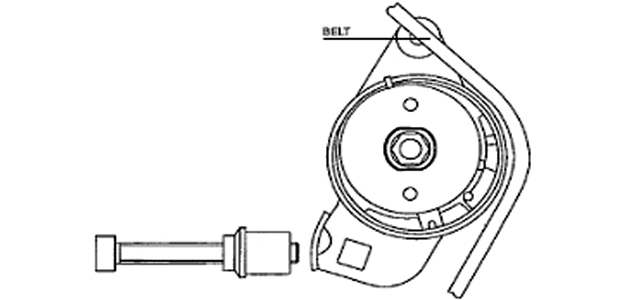

The tensioner should be mounted flat on the bracket. Install the timing belt around the crankshaft and camshaft sprockets and the tensioner as per drive layout (see below).

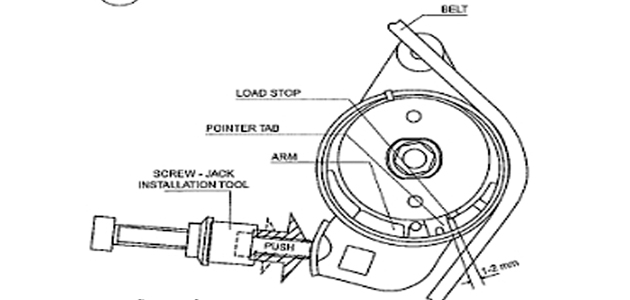

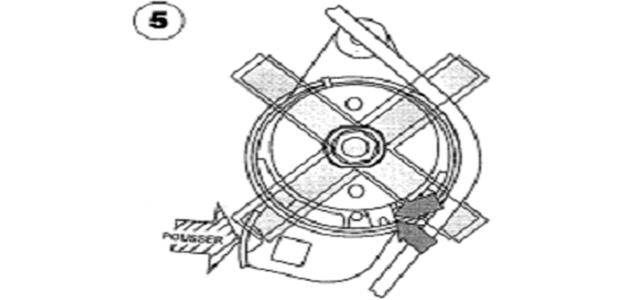

Push the tensioner into the belt with the screw-jack installation tool. The tensioner assembly will move against the belt and the arm will eventually start to move clockwise.

Rotate the crakshaft

Continue pushing the tensioner until the load stop on the arm and the pointer tab on the front plate are separated by 1-2mm (see below).

Caution: Don’t push the tensioner beyond this point. Continued travel of the tensioner arm may result in damage or deformation of the tensioner’s pointer (see below).

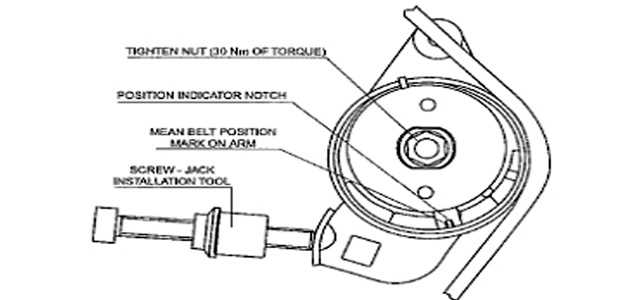

Rotate the crankshaft two complete revolutions manually for proper seating of the belt until the crankshaft is repositioned at the TDC position. Retract the screw-jack installation tool slowly until the mean belt mark on the tensioner arm aligns with the position indicator notch in the pointer tab (see below).

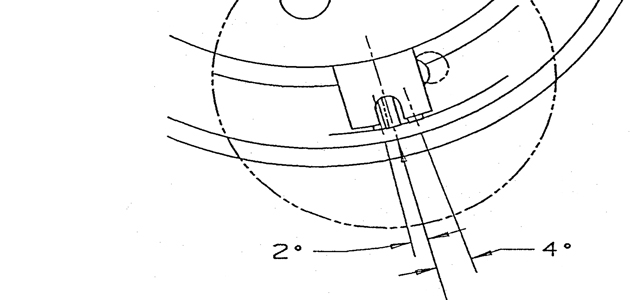

Torque the mounting nut to 30Nm using a torque wrench. Note: When the engine is started and idling at room temperature (20°C), the mean belt position mark on the tensioner arm should oscillate evenly about the position indicator notch. The mean belt position mark oscillating +2 to -4° of the position indicator notch centreline is within the permissible tolerance range (see below).