Steve Beynon of FLIR Systems takes a look at the opportunities that thermal imaging cameras can open up for automotive technicians.

Thermal imaging: too costly for the motor trade? The short answer is no.  It’s now a technology that is not only affordable but one which can help technicians work smarter, faster and more profitably and it is increasingly finding its way into garages and the wider aftermarket throughout the UK.

It’s now a technology that is not only affordable but one which can help technicians work smarter, faster and more profitably and it is increasingly finding its way into garages and the wider aftermarket throughout the UK.

The tumbling entry cost has not been the only driving factor in its take-up by the motor trade. Thermal imaging is much easier to use, too. Cameras are intuitive so there is no need for any formal training and the technology can be applied to a wide range of problems, making payback super quick. But before we look at applications, let’s start by defining what a thermal imaging camera does.

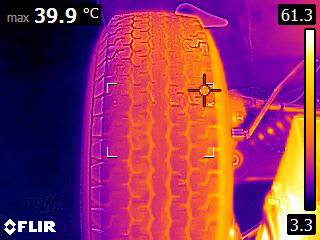

When an electrical or mechanical system is faulty or not working efficiently, it operates above – or sometimes below – its normal temperature. This is vital information that can be picked up by a thermal imaging camera.

Such cameras are non-contact devices that detect heat and convert it into an electronic signal which is then processed to produce a thermal image and perform temperature calculations. It gives technicians a sixth sense, providing visual proof of a problem and its severity.

Recent innovations, particularly in detector technology, have significantly broadened the choice of camera products available. The development, for example, of a thermal imaging detector no bigger than a mobile SIM has paved the way for a new breed of instruments like the imaging thermometer.

Such a device, sitting between a spot thermometer and a thermal imaging camera, doesn’t have the sophistication of a thermal imaging camera but it allows the user to see heat patterns, measure temperature and store measurement data.

The next step up is a basic troubleshooting camera which is often a surprisingly sophisticated tool, despite its relatively low cost. The choice of types is now wide, from pocket portable to torch-style models. Pay close attention to detection resolution though. Pixel numbers matter. More pixels give users clearer images and more precise measurements. One of the great things about thermal imaging is that it can be applied to a wide range of tasks. It allows the technician to ‘see’ blockages in exhaust systems or radiators, and detect hotspots caused by mechanical misalignment, a misfiring cylinder or electrical connection issues. It’s also ideal for checking the efficiency of heated seats or aircon systems. Such scope makes the relatively low cost of thermal imaging even easier to justify.