Defective steering and suspension parts on a vehicle can not only affect the geometry and handling, but also result in MOT failure. Worn or damaged parts can cause serious instability when driving and increase the potential of a road accident.

Reasons for parts failure

One of the main reasons for parts failure is our deteriorating road quality and speed humps. For example, if one wheel drops into a pothole, the link rod is subjected to a massive shock loading. If this occurs in cold and wet conditions – when materials used in the ball joint part of the rod are in a more brittle condition – then the ball joint may become vulnerable to water and grit ingress with the inevitable result of total failure.

Change to MOT legislation

Back in January 2012 the Department of Transport added a number of new mandatory tests to the annual MOT to comply with a revised European testing directive. This aims to harmonise minimum test requirements across Europe and one important change affects the way steering and suspension components are checked.

As such, missing or split/damaged dust covers on steering and suspension ball joints will result in failure if they allow dirt to enter the joint. For this reason, FAI argues that replacing only the rubber boot/dust cover on old ball joints, tie rod ends and link rods can be potentially dangerous and lead to failure.

Once a rubber boot or dust cover splits, water, salt and grit canfind their way inside and start to corrode the ball joint.

Once the boot has split, water, salt and road grit will have already started to corrode the inner surfaces of the ball joint. Simply fitting a new boot can seal in and hide this damage, providing a false sense of security for the driver. Despite the damage being hidden, the most likely outcome is that the ball joint will break up and develop excess play, causing tyre wear and unpredictable handling. Eventually the ball joint will fail, causing loss of control of the vehicle.

Once the boot or dust cover on safety parts like ball joints, tie rod ends and link rods has split, the only safe option is to replace the damaged joint entirely.

Replacing in pairs

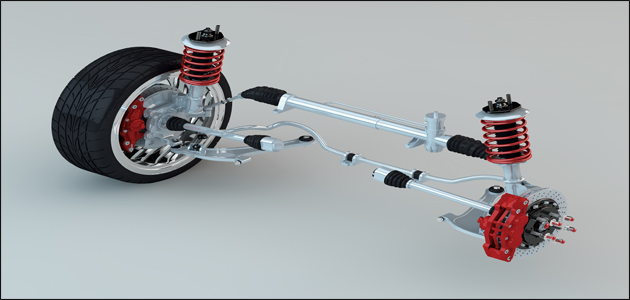

During the MOT test the entire steering and suspension system will be checked for function and security with the inspector looking for wear or damage within all components. The system will also be checked for movement within the links and joints.

Additional checks for corrosion and breakages will be required, including coil springs and top and bottom suspension mountings, suspension links, upper and lower wishbones, anti-roll bar bushes and link rods.

It is our recommendation that if a defective part is found it is always a good safety principle to replace in pairs. Both parts will have the same amount of wear and replacing only one side can seriously affect the handling of the vehicle.