Steering and suspension parts are safety critical items so, as a result, they must be designed to withstand particularly high loads. Component wear is a common cause of damage and can have detrimental effects on the vehicle‘s road-handling ability and safety, therefore immediate action is always required.

Factors that can accelerate rubber-to-metal part wear include: material fatigue, excessive temperatures, contamination (by engine oil, for example), adverse climatic conditions (exposure to ozone or oxygen), continuous overstress (such as overloading), high levels of strain (poor road conditions), incorrect matching of components during assembly and the use of undersized components.

The MEYLE technical team sees many cases of damage to steering and suspension parts, so it has highlighted (below) three of the most common problems that often occur, along with details about how these can be solved.

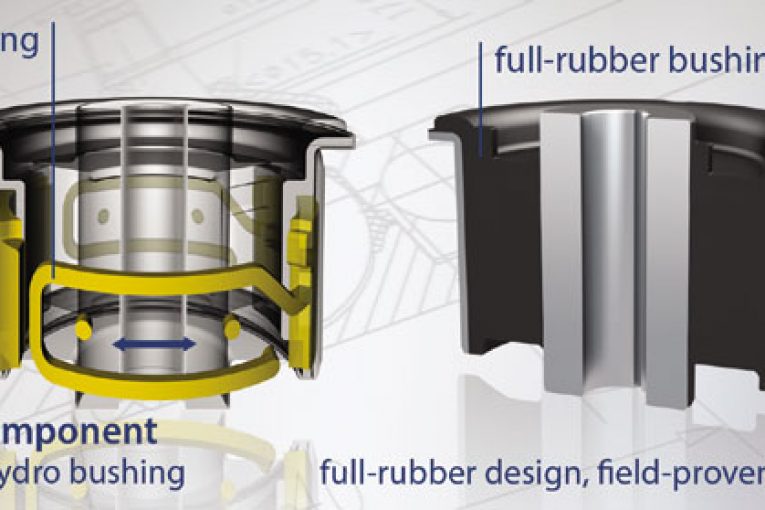

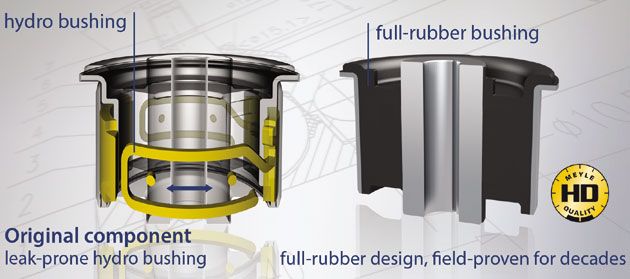

LEAKING HYDRO MOUNTS

THE PROBLEM

Subjected to excessive power levels, hydro mounts are likely to spring a leak and lose their damping capacity. Variations in the part‘s stiffness characteristics can then have a detrimental effect on steering precision.

POSSIBLE CONSEQUENCES

■ Unresponsive steering

■ Steering ‘play’

■ Reduced driving and braking safety

■ Brake judder

■ Reduced driving comfort and unpleasant driving noise

MEYLE´S ADVICE

You should check the hydro mount during every brake service and consider replacing with durable full-rubber bearings, such as those available from the MEYLE-HD range.

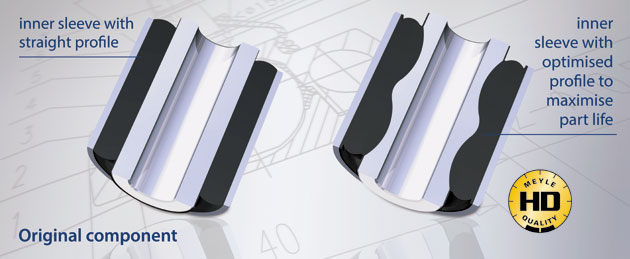

INNER SLEEVE ON CONTROL ARM MOUNT TORN LOOSE

INNER SLEEVE ON CONTROL ARM MOUNT TORN LOOSE

THE PROBLEM

Many control arm mounts are undersized, causing them to fail prematurely. The rubber-to-metal bond becomes loose as a result of excessive loads.

POSSIBLE CONSEQUENCES

■ Unresponsive steering and steering ‘play’

■ Reduced driving and braking safety

■ Reduced driving comfort and unpleasant driving noise

MEYLE´S ADVICE

MEYLE-HD control arm mounts feature a profiled inner sleeve to maximise parts durability. The rubber profile is contoured to deliver excellent load-carrying capabilities and a premium bonding agent provides high-strength adhesion and excellent protection against under-paint corrosion. You should install full-rubber bearings in preloaded condition only.

RUBBER SLEEVE FISSURED AND POROUS

THE PROBLEM

THE PROBLEM

The sleeve is made of low-grade materials, which are not weather-resistant (e.g. to ozone, moisture or salt) or the materials chosen are incompatible with the grease applied, causing the rubber to disintegrate from the inside to out.

POSSIBLE CONSEQUENCES

■ Lubricant egress and moisture ingress

■ Heavy wear caused by insufficient lubrication

■ Corrosion within the ball joint

■ ‘Play’ in the wheel control components

■ Reduced driving and braking safety

■ Reduced driving comfort and unpleasant driving noise

MEYLE´S ADVICE

MEYLE parts are made from premium-grade materials that are carefully matched to one another. In addition, special MEYLE high-performance grease should also be used. The perfect combination of the system‘s individual components will ensure maximum service life.