Gates explains some things every technician must know before changing the timing belt on VAG’s EA211 engine.

While the VAG EA211 three-and-four-cylinder engines have been on the market for almost a decade, they still do not make for run-of-the-mill maintenance. Their special, oval sprockets (which we at Gates call ECO Sprockets), certainly have something to do with that. Let’s take a look at their special characteristics, and the main issues to keep in mind while changing the timing belt on these engines.

The VAG EA211 engines are used in different VAG platforms, including: 1.0 litre, 1.2, 1.4 and 1.6. The timing belt drive uses an automatic tensioner with flanges to guide the timing belt at the same time.

Three-cylinder engine

In the introduction we mentioned the oval camshaft pulleys that are characteristic of these VAG engines.

Opening the valves of an engine requires a certain amount of force. The forces arising from valve springs opening and closing the valves of the cylinder head create cam torque vibrations or angular vibrations that heavily impact belt drive dynamics. As a result, the VAG EA211 three-cylinder engine has quite a large natural imbalance. To counter this imbalance, specific oval camshaft gears (ECO Sprockets, in Gates terminology) have been used with 120° intervals. ECO Sprockets allow of variations in belt length, both on the tight and on the slack side of the drive, and this reduces the peak of belt forces in the engine.

Four-cylinder engine

The four-cylinder engine uses an oval crankshaft torsional cancellation sprocket or gear. Due to a temporary reduction of the radius during the working stroke, the timing belt is slackened. This phenomenon will result in reduced forces and less vibration in the timing belt drive.

The benefits of the oval sprockets

In both the VAG EA211 three- and-four-cylinder engines, the use of oval ECO Sprockets leads to:

- lower timing belt forces, which means the tension force of the tensioner also decreases

- lower friction and mechanical stress in the entire timing belt drive

- reduced vibrations and noise levels

- load reduction affecting all components

- increased system life

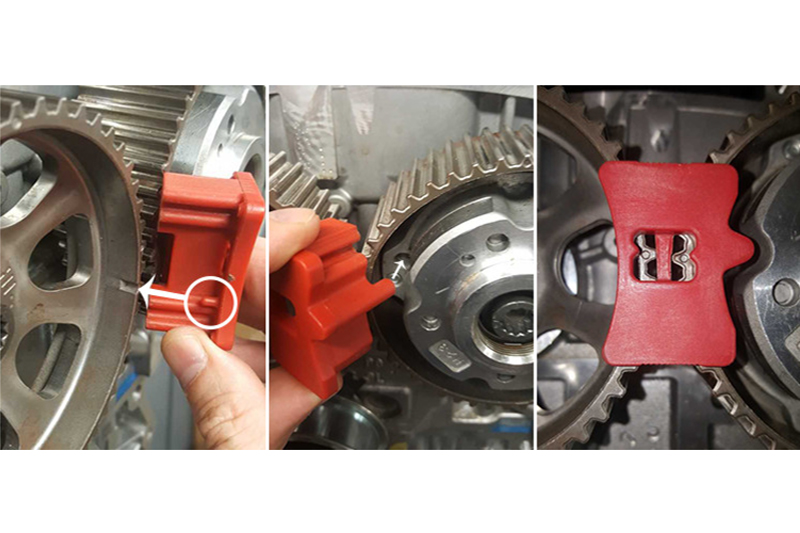

Changing the timing belt

Changing the timing belt on VAG EA211 engines requires using the proper tools. Consult Gates’ website to identify which tools are required for your exact vehicle. In the case of even a minor misalignment, the engine will have difficulties starting after you are done working on it. In addition, belt life will be drastically reduced, because the belt will be exposed to too many forces.

The camshaft pulleys need to be loosened while holding the pulleys in place. Again, if this is not done correctly, belt tension fluctuation will increase.

The water pump, which is integrated into the thermostat housing and driven by the engine’s exhaust camshaft at the other side of the engine, also needs to be replaced. For this, Gates offers four kits containing all required parts on the timing belt side as well as the water pump and its separate toothed belt, namely: KP15680XS-1, KP15680XS-2, KP25680XS-1 and KP25680XS-2.

The VAG EA211 engines have a dual cooling system with two thermostats: one for the cylinder head opening at 87°C (Gates ref TH59787G1) or at 80°C for MPI engines, and one for the cylinder block at 105°C.

To conclude, we would like to share three best practices that you should adhere to whenever you change the timing belt on VAG EA211 engines. First, we advise you to change the water pump together with the timing belt. Replacing both parts at the same time is not only more efficient and safer; it also avoids costly comebacks, because it prevents the scenario of a customer having to return for a second repair when they just had a new belt and tensioner installed and then the water pump fails. Second, a timing belt should never be kinked, bent or twisted. And third, it is imperative to adhere to our installation instructions, which are available digitally, as well as to bleed the cooling system according to the manufacturer’s prescriptions. After all, with these engines you not only have to carry out your actions in a specific order; you also have to use diagnostic software to prevent overheating and other problems.