Given the unique design of Gen2 wheel bearings, installation can be a delicate process. The components must be installed with the right level of force, which is applied at a very precise point, in order to press them into position.

Pichler’s unique Universal Gen2 Wheel Bearing Kit is fully adjustable, fitting all Gen2 wheel bearings currently on the market – from a Smart car to a Mercedes Sprinter. The kit enables technicians to undertake removal and re-fitment directly on the vehicle for quicker, safer repairs and avoids the risk of damaging expensive components.

Available as a complete manual unit, it can also be upgraded with hydraulics to make it faster and can be upgraded to work with Gen3 Bolted wheel bearings.

Special offer price!

Pichler Tools has recently updated this revolutionary kit, which is now available for the special price of £899 + VAT until the end of April 2016. To take advantage of this great offer call 01335 360759 or visit www.pichler-tools.com.

INSTALLATION ADVICE – WHAT YOU NEED TO KNOW

1. It is vital that technicians adhere to the correct procedure when dismounting and – more importantly – mounting a Generation2 Wheel Bearing.

2. A common problem experienced in workshops is technicians struggling with the correct identification of a Gen2 bearing, and being unaware of the damage that can be caused by incorrect fitment.

3. When asked, technicians will often remark that Gen2 bearings are: “the ones with the clips that are hard to fit”. It is frequently assumed that all Gen2 bearing units have a retaining clip, which is absolutely not the case, as most Ford and Volvo Gen2 Bearings don’t feature a clip.

4. Because a Gen2 bearing unit is a complete bearing/hub assembly, it is not possible for the technician to press the bearing into the housing knuckle in the conventional way (by applying the force on the outer bearing casing [race]), because the flange unit is already mounted and is therefore in the way.

If force were to be applied onto the flange, the force would be transmitted through the inner bearing ring, to the rollers and then to the outer ring. This would damage the bearing – something that the technician is often unaware of – and water ingress and premature failure will occur.

5. The correct procedure to fit a Gen2 bearing does require the application of force to the outer race of the bearing. This is done by means of special tooling. Some of the kits available require different size ‘brackets’ to fit different size diameter bearings.

Pichler Tools’ Universal Gen2 Wheel Bearing Kit is 100% adjustable, and fits all diameter Gen2 bearings currently available, up to (and including) a Mercedes Sprinter van. With this kit, the bearing can be removed and replaced directly on the vehicle, resulting in less dismounting of components and avoiding the common issue of trying to level a bearing unit on a workshop press. The kit also allows for the bearing replacement, without having to disturb the ABS sensor, which, when interfered with, can often lead to more problems and have cost implications.

HOW TO USE THE TOOL

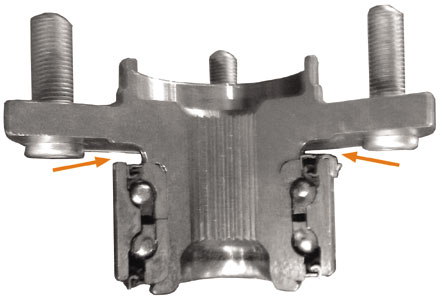

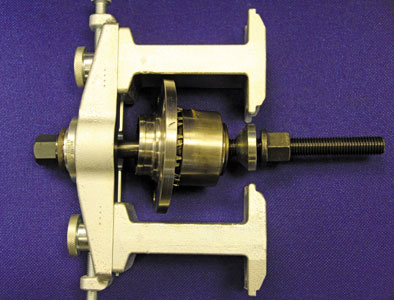

1. An example of a Gen 2 Wheel Bearing.

2. The arrows show where the force can be applied.

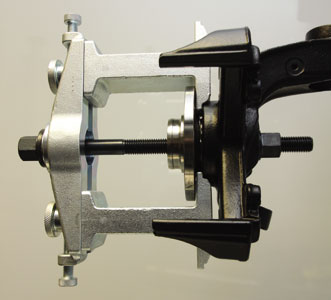

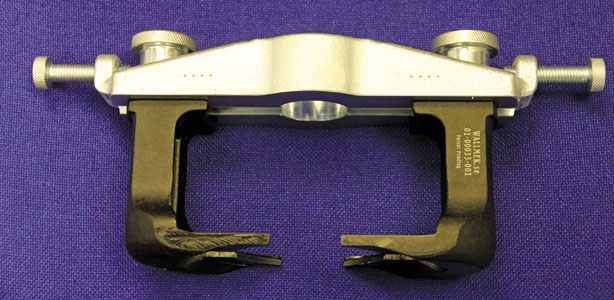

3. The dismount tool is set up.

4. The dismount tool is now ready to disassemble.

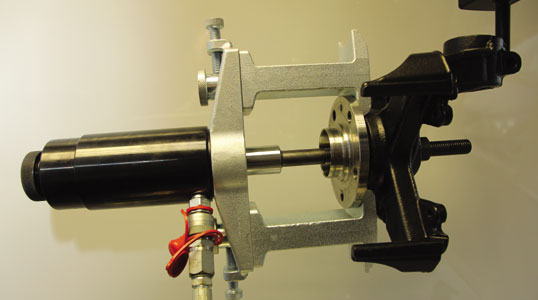

5. Here we can see the back of the tool for disassembly.

6. An optional hydraulic unit can also be used for easier disassemble.

7. This picture shows the bearing removed half-way.

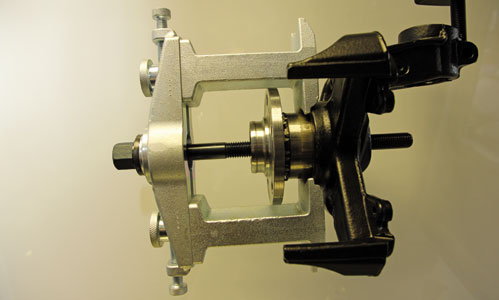

8. The bearing assembly is removed.

9. The install legs are now fitted to the tool.

10. The bearing/clip is mounted into the tool, ready for installation.

11. A close up view of the bearing loaded into the tool, showing where the force will be applied.

12. The pulling plate.

13. The bearing is mounted half-way.

14. The bearing and retaining clip are fully installed.

15. The completed bearing installation.

Take your Pichler

Pichler Tools creates specialist tools for the automotive industry, to simplify complex service and repair tasks. Developed in conjunction with technicians seeking to deliver quick and professional maintenance, the company delivers innovative time-saving solutions for modern workshops.

The Pichler product range now includes over 12,500 items, catering for specialist work on timing, braking, suspension, common rail diesel injection systems and much more.

To find out more visit www.pichler-tools.com

Pichler Tools will be appearing at all four MECHANEX shows in 2016, starting at Alexandra Palace in North London on April 19 & 20.

The show is completely free to attend and tickets can be booked online, or by calling 0844 888 8339.

For more information follow @MECHANEXShow on Twitter, or visit the MECHANEX website.