Clarios, the global battery manufacturer behind the VARTA brand, estimates that as of 2020 every third car that enters a workshop will be equipped with start-stop technology. This presents workshops with a new challenge when it comes to changing a car battery. Here’s why…

Battery fitment is becoming more complex for workshops and installing a replacement battery on a new vehicle can take well over an hour. This is due to the increasing number of batteries being installed in difficult-to-reach places, such as under the seats or behind panels inside the cabin. The number of steps to change a battery is therefore increasing, as removing seats and panels takes time, not to mention the operation of diagnostic equipment for reprogramming the battery to the Battery Management System (BMS).

For example, take a Volkswagen Touareg. It now takes 28 steps to remove the old battery and install the new replacement battery, taking 72 minutes! So, don’t be afraid to charge a customer for labour time on these types of time-consuming battery jobs.

Models old vs models new

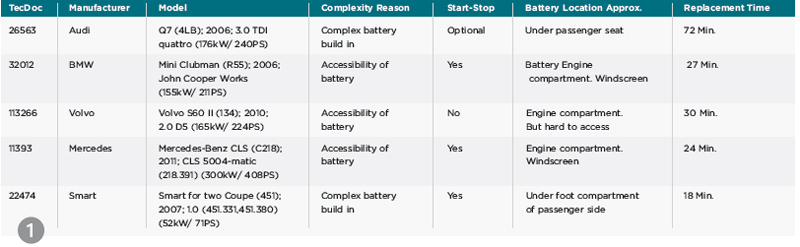

As you can see in Fig 1, some vehicle models have particularly complex fitments due to the accessibility and location of the battery. When you compare this to an older vehicle’s battery change, which could take five to 10 minutes, you can see why charging additional labour time is required.

Are AGM and EFB really needed?

Many drivers are surprised when a replacement battery for their vehicle with a start-stop system costs more than was expected. However, when you look at the power a battery is required to provide on these new vehicle types, it is easy to see why. Absorbent Glass Mat (AGM) and Enhanced Flooded Batteries (EFB) have been designed to cater for increasing electrical demands; fitting a traditional flooded battery will not provide the power needed to accurately engage the start-stop function or cope with the additional vehicle starts. Plus, onboard electrics are all commonplace on the latest vehicle types, which is certainly not true of 20 years ago.

Like for like

When replacing an old battery, it is important to replace like-for-like or like-for-better technologies, and not to fit a conventional lead acid battery to a vehicle with a start/stop system. Fitting the correct battery technology type first time, will keep your customers happy and on the road, helping you to avoid costly repeat repair work. If in doubt, consult the vehicle handbook or you can check the VARTA Partner Portal www.rdr.link/AH023 to ensure you’re fitting the correct battery technology.

Importance of testing every vehicle

To ensure a complete and thorough service, VARTA recommends performing a battery test on all vehicles coming into a workshop. With most vehicles entering the workshop on average once a year, it is important for a technician to perform a battery test on the vehicle, as they likely won’t see it for at least another 12 months – even when it’s arrived for an unrelated job. With 40% of national breakdowns occurring as a direct result of battery failure, there are many car batteries not being checked until it is too late. Through accurate testing, technicians can identify batteries that are in a poor condition and prevent issues further down the line.