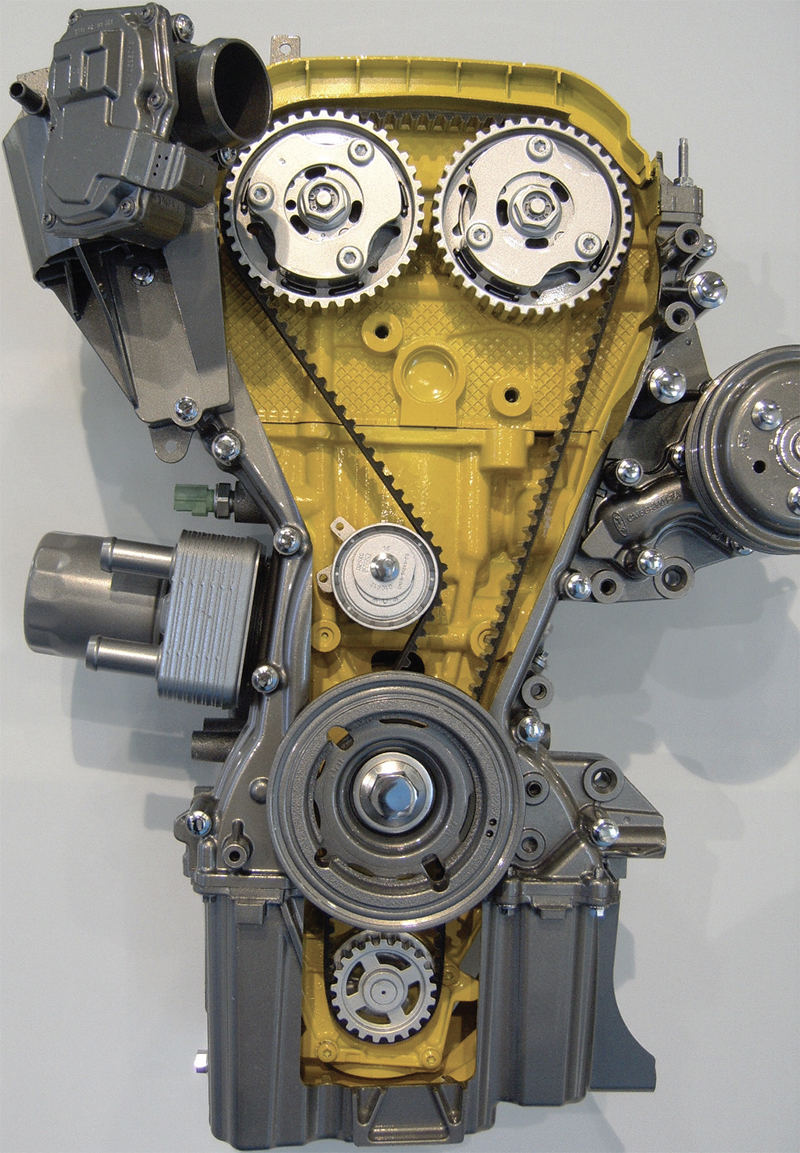

In this month’s Belt Focus, Dayco shines a light on the belt-in-oil system on Ford’s EcoBoost ‘Fox’ engines.

Dayco, the company that pioneered the belt in oil (BIO) innovation on behalf of vehicle manufacturers such as Ford and VW, is highlighting the importance of regular maintenance in line with the VMs’ scheduled service intervals, to ensure the ongoing reliability of these engines.

Taking the Ford 1.0-litre EcoBoost ‘Fox’ engine, which is used in multiple Ford applications including the B-Max, C-Max, Ecosport, Fiesta, Focus and Mondeo, as an example, according to the manufacturer’s service schedule, the timing belt must be replaced at 150,000 miles or every 10 years, whichever comes soonest. When it comes to the Tourneo Connect and Courier however, the replacement mileage is slightly lower, at 140,000 miles.

“Although the BIO innovation is a fantastic solution, which helps this small and efficient engine to deliver incredible levels of power, alongside exceptionally low emissions and excellent fuel economy, depending on the quality of the fuel it uses and the type of journey it undertakes, the engine can sometimes be prone to oil contamination, which has the potential to affect the belt,” explains Dayco’s National Sales Manager, Steve Carolan. “It is therefore imperative that workshops highlight the importance of following the VMs’ scheduled replacement intervals to their customers.

“On a practical level, there are also some best practice guidelines that technicians can follow to help them assess the condition of the belt in between the specified replacement interval, the first of which is to assess the condition of the oil.

“This is easier than it might appear as the presence of petrol in the oil is generally noticeable due to its strong odour, so rather than undoing the drainplug and walking away, whenever carrying out a scheduled oil and filter change technicians should check for the smell of petrol fumes. If this is detected, further investigation must be made as the failure of the belt will have catastrophic consequences to the engine.

“Unfortunately, checking the condition of the belt is not straightforward, but a sensible starting point is to check the strainer that the oil will have passed through when draining from the sump, because it’s possible that fragments of the belt or deposits of material that have been dislodged as the fuel attacks the belt material, will be left behind.

“If any evidence of debris is found, the next step is to remove the camshaft cover as this is the only practical way to properly assess the belt’s condition as it allows technicians to examine the back, which will reveal whether the contaminated oil has begun to degrade the surface of the belt. At this point it’s important to state that some moderate increase in the width of the belt, commonly referred to as belt swell, is not an issue, unless of course it’s so excessive as to cause the belt to foul, but this will be evident if there is damage to its edges.

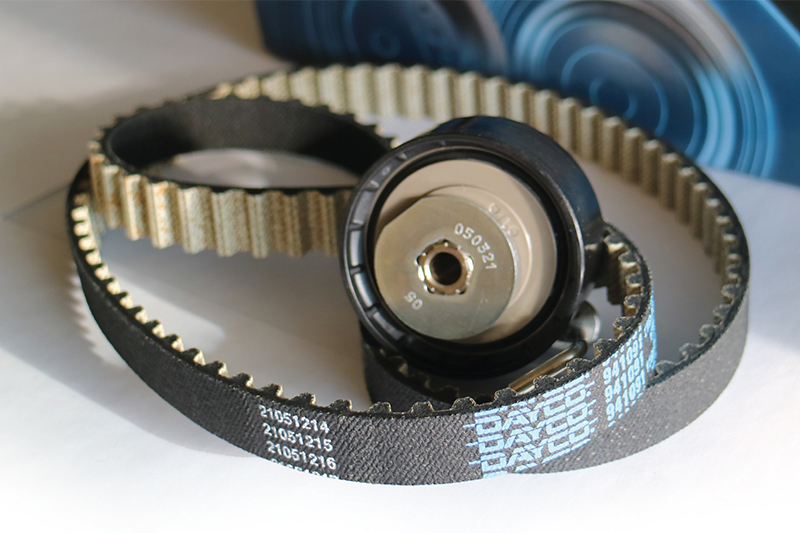

“Naturally, should the belt need to be replaced, as the original equipment supplier for both the timing and oil pump drive systems for these engines, Dayco has replacement kits – either KBIO02 or KBIO03 – in its aftermarket range.

“Finally, we’d encourage workshops to be proactive with their customers and, in addition to highlighting the necessity of the belt checks and replacement interval, make them aware of the consequences in terms of the damage to the engine and the cost to repair it, should the belt fail.”