Nissen offer some top tips for keeping the A/C condenser in mint condition.

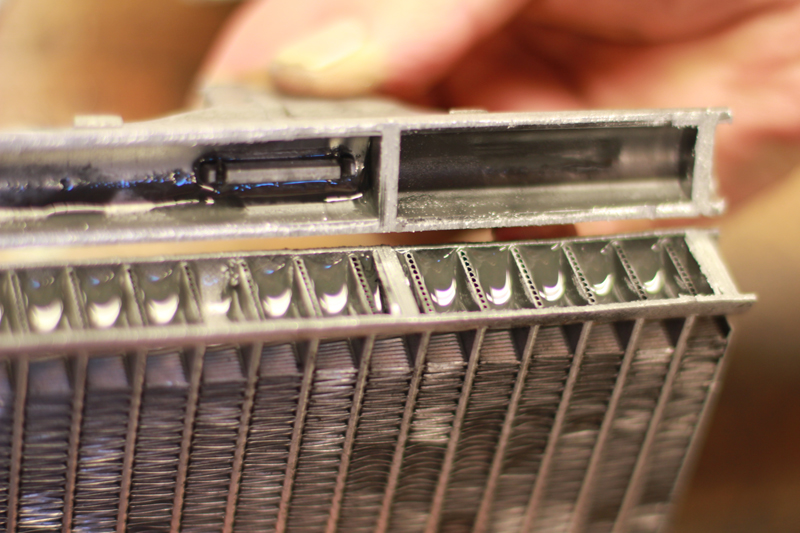

The condenser is a crucial component for ensuring correct A/C system operation. Placed inthe front of the car, and typically attached to other heat exchangers in the engine compartment, it ensures that the refrigerant changes from a gas to a liquid form. This is achieved through the condensation process,

where the refrigerant heat is extracted and exchanged with the ambient air.

PROBLEM

When impurities develop in the system, the thin channels of the condenser will quickly clog. This can

restrict the refrigerant flow, eventually reducing the unit’s ability to exchange heat. In most cases this will eventually cause overpressure in the system, which is extremely harmful for the compressor.

Condensers with micro tube technology tend to be the ones at the greatest risk. While micro tube technology offers an outstanding cooling performance, the thin fins are more exposed to stoppages. As the flow is compressed to a more confined area, fewer impurities are needed for clogging to occur.

SOLUTION

To keep the condenser in good condition, the receiver dryer must always be replaced during a compressor replacement, if the circuit has been exposed to ambient air, or the system has run empty, due to leakages. If none of these events occur, it’s recommended to replace the receiver dryer every second year.

Furthermore, you should always perform a system flush after a compressor breakdown.

Make sure that no flushing agent residues remain in the system after flushing. Always use the recommended oil and additives. Replace the condenser in cases of doubt.

Common cause for condenser inner clogging.

No/poor flushing

A thorough system flush must always be performed prior to a new component

installation – especially after a compressor seizure. When a compressor has seized, metal chips

can break off and cause clogging in the system. Furthermore, carbonised oil particles, developed

due to the compressor overheating, can cause clogging in the system and must be flushed.

Wrong use of additives

Incorrect additives, or improper application of additives, can cause system contamination.

This is often caused by crystalised leak-stop agents and/or Teflon that has peeled off inner parts

of the compressor. Teflon peeling off can be caused by aggressive, and not properly removed,

cleaning agents.

Incorrect lubricant

A lubricant with a too high viscosity can easily clog the condenser – especially

condensers built in micro tube technology, due to the confined flow in the fins.

Receiver dryer in poor condition

Poor condition of the receiver dryer means that it will become less efficient in filtering

particles, increasing the risk of impurities flowing through the system. This will eventually lead

to clogging of the condenser and other components.