The inductive sensor (inductive type pulse generator) works on ‘Faraday’s Law’ and the basic contents of the sensor are a coil (winding), a magnetic field and ‘movement’. By using this principle, it is possible to measure angles, distances and speeds without contact, thus the sensor is wear-free.

The functions of an inductive sensor include: speed detection (on the crankshaft or transmission for example), crankshaft position, driving force for ignition triggering, throttle position (last signal), detecting the steering angle (‘steer by wire’ for ESP), pedal sensor (electronic throttle, driver desire), brake pedal sensor (electrically actuated brake) and level sensor (for the chassis controlled system or the leveling system).

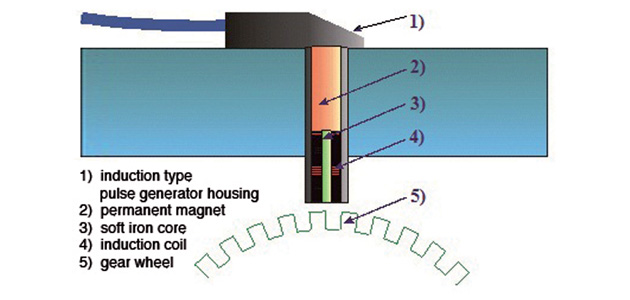

A good way of explaining the role of the inductive sensor is to look at the crankshaft sensor as an example. The crankshaft sensor measures the engine speed and consists of a permanent magnet and induction coil with a soft iron core. A ring gear is attached to the flywheel as a pulse (movement) generator with a small air gap left between this and the inductive sensor.

The magnetic flux through the coil depends on whether the sensor is facing a tooth or a tooth space – a tooth concentrates the flux leakage of the magnet and a tooth space weakens the magnetic flux. If the flywheel, and thus the ring gear rotates, then a magnetic field change is caused by each individual tooth. The change of the magnetic field subsequently generates an induction voltage in the coil.

The speed of the flywheel is measured by the number of pulses per time unit and, by way of deliberate teeth spacing in the arch, the control unit recognises the current position of the engine. On solenoid valve controlled engine management systems, trigger wheels are used and the reference mark is defined by one or two missing teeth. The engine speed is a main control variable for the calculation of the petrol mixture and the ignition timing.

What happens if the sensor fails?

■ The engine may suspend

■ The engine can be at standstill

■ A fault code is generated and stored

Possible causes of failure

■ The winding has short-circuited

■ The cable has broken or short-circuited

■ Mechanical damage to the ring gear

■ Strong pollution

■ The air gap is too large

How can you troubleshoot the sensor?

■ Read the error memory

■ Check the connections

■ Check for dirt or damage