The winter can play havoc with ignition components as cold, damp conditions increase the stress on coil units while water ingress from salt treated roads can accelerate the deterioration of poorly fitting spark plug boots and coil terminals.

Most modern engines have done away with the old fashioned distributor ignition system, instead using low-voltage electronic signals from the engine-management system to trigger the spark. Using a DIS (distributor-less ignition system) eliminates the problem of damp getting into the distributor cap, however damp issues can still affect modern ignition systems.

Cambiare’s programme

With over 1,100 part numbers in their ignition catalogue, Cambiare boasts one of the UK aftermarket’s most comprehensive ignition programmes.

Troubleshooting: Ignition coils

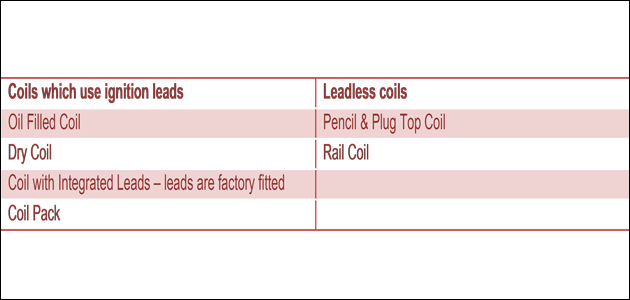

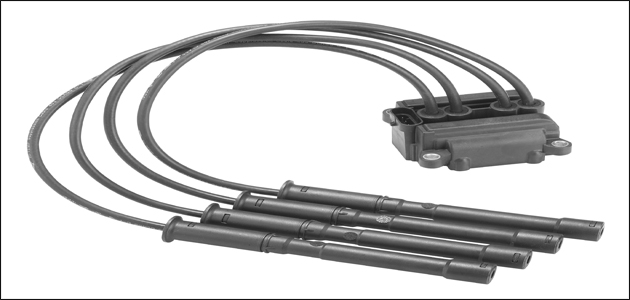

The coils convert the 12V input from the battery to the 25,000 to 30,000 volts needed to create the spark. Older type coil systems are connected to the spark plug via the ignition lead while the new systems are directly connected to the spark plug, dispensing with the lead altogether.

Common fault codes pointing towards possible ignition coil faults include:

P0351 – Ignition coil A, primary/secondary circuit malfunction

P030X – Misfire detected in cylinder 3 (in this case)

P0300 – Random/multiple cylinder(s) – misfire detected

Filed or failing coils and coil packs normally can be detected through a number of symptoms, including:

>Poor idle or poor engine running at low speed

> Misfire

> Poor fuel consumption

> Loss of power

> Poor starting

Engine diagnostic tools can help identify the source and location of the fault, but these should be used with caution as they can lead you to an incorrect diagnosis. While fault codes will often identify where the fault is, they won’t always identify other systems that are affected by the failure and what could even be the cause of the failure.

Troubleshooting: Ignition leads

While most newer vehicles are fitted with coil packs, pencil coils and rail coils, there are still plenty of coil and lead systems out there. Around 16 million vehicles (of 15 years or younger) on UK roads rely on ignition leads, and this population is actively growing thanks to the new generation of small engine vehicles such as Fiat’s 500, Panda and Punto models; Ford’s Fiesta and KA brands and the Smart Car.

OE manufacturers use three technologies for ignition leads:

Copper core: a very high quality cable which is reflected in the price. Used by mainly German vehicle manufacturers

Wire wound core (reactive): favoured by the French vehicle manufacturers such as PSA and Renault as well as SAAB and Volvo

Resistive core: the most popular and inexpensive type of lead favoured by British, Japanese and American vehicle manufacturers

Oil, coolant and fuel vapour cause connector contacts to oxidise and corrode and the plasticisers to escape from the plastics used in the casing. The result is a brittle lead. Damage to the lead insulation causes the ignition voltage to flow to ground, resulting in misfiring, rough engine running and unburned fuel in the catalytic converter. Consequently, technicians should be getting into the habit of regularly inspecting ignition leads and replacing them at the first sign of ageing.