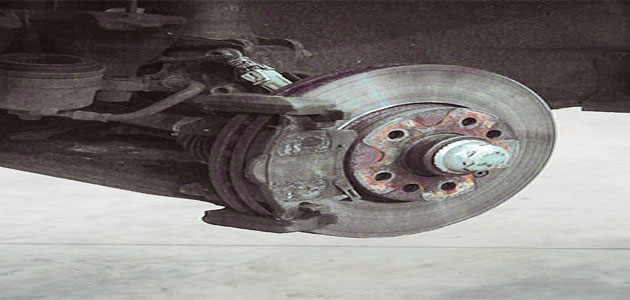

1. Start of brake repair – Visually check the brake disc and/or pads for signs that they may be reaching their wear limit. Before starting the brake repair, all relevant components in the area of the axle and the hydraulic system must be checked. It is important to replace any defective parts.

2. Remove rust from the contact surfaces and hub – After dismantling the old brake discs, remove rust from the contact surface and the hub edge using appropriate tools (e.g. a wire brush, Emery paper, etc). Make sure you do not damage the wheel hub! The calliper, which is still connected to the hydraulic system, must be fastened so that no tensile load is exerted on the brake hose.

3. Cleaning the contact surface and hub – Use a brake cleaner to clean the bright metal contact surface. We recommend checking the cleaned hub with an appropriate measuring gauge for possible lateral run-out deviations.

4. Remove rust from the guide shafts of the calliper bracket – Depending on the design, remove rust and residues from the guide shafts of the dismantled calliper bracket using a wire brush and/or calliper file. Do not damage the calliper bracket! Visually check the bracket for damage.

5. Greasing the guide surfaces of the calliper bracket – Grease the cleaned guide surfaces of the calliper bracket with a nonconductive, heat resistant and solids-free (non-metallic) agent such as Mintex CERA TEC. Do not use copper paste!

6. Fitting the brake disc – Fit the new brake disc on the wheel hub and – depending on the type and system – fasten with the retaining screws. We recommend measuring the newly fitted brake disc for lateral run-out approximately 15mm below the maximum radius using a dial gauge. Ideally, this measurement is performed with a properly mounted wheel.

7. Moving back the brake piston – The brake piston must always be moved back using appropriate adjusting tools in order to prevent the piston jamming or twisting. In doing so, attention should be paid to the different versions of the calliper and/or the brake system, as well as to the manufacturerspecific requirements and special tools.

8. Greasing the contact points – Where damping lacquer coatings or damping shims are fitted, metal-free antisqueal lubricant is not required. Only use the lubricant (such as Mintex CERA TEC) in the area of contact of the pad on the guide shafts. Lubrication is only vital in the area of contact points of the pad and on the guide shafts. The torque settings and specifications/guidelines of the vehicle and system manufacturers should be observed in all steps of the repair process.