The Draper Expert Mobile Hydraulic Spring Compressor (56191) enables you to safely and speedily compress springs during repair or maintenance of suspension strut and damper assemblies. Here, Draper explains how to use the machine safely and effectively.

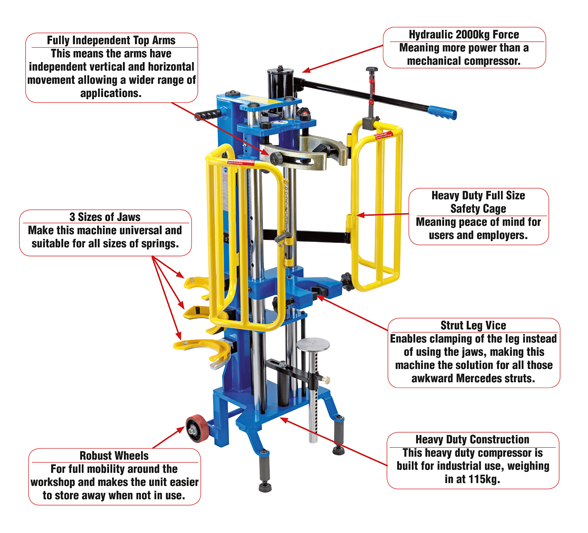

The Expert Mobile Hydraulic Spring Compressor is an industrial machine that offers a ‘total solution’ for all springs, including all Mercedes springs, without the need for additional expensive adaptors. Its all-steel construction and five tonne manual hydraulic ram securely clamp and easily compress a multitude of coil springs.

Being completely mobile, it allows you to take the machine to the job. And, because it is manually operated, there is no trip hazard from trailing air or power lines. Its design keeps the suspension unit in line throughout the process, making dismantling and re-assembly of the suspension unit far quicker and safer.

What kind of springs can you use?

Linear springs – standard straight springs with a constant stiffness.

Progressive springs – these gain stiffness as they compress.

Side load springs (aka banana springs) – ease force on the strut.

Mini block – compact and progressive.

Before you start: The Hydraulic Spring Compressor does not require assembly. However, there are a few parts which, depending on the job, will need to be fitted before use. Select the correct clamp yoke from the three supplied with the machine, or the 30-70mm fixing jaw and slide in the hydraulic pump handle.

Important:

Always ensure the safety guard is closed before operating the compressor.

Stand in front of the compressor when using it, keeping your hands away from the fixing base and shock absorber.

■ Always lock the pump handle when it’s not in use.

■ Ensure the compressor is stable and on a flat, level surface able to support the weight of the unit.

■ Adjust the height of the lower fixing base according to the type or size of the shock absorber.

■ If using the lower fixing jaw, refer to the vehicle manufacturer’s guidance for the correct locking position.

■ Only qualified technicians should operate the compressor and only after they have read and understood the instruction manual.

How to:

Step 1 : If you’re using a fixing yoke, put the lower section of the shock absorber spring on the fixing yoke and rotate the shock absorber so that the spring can be held as low as possible.

Step 2: Ensure all of the bolts of the fixing yoke have been tightened.

Step 3: Adjust the lower supporting base to support the base of the shock absorber.

Step 4: Adjust the upper fixing jaws according to the size of the shock absorber and spring. Ensure all bolts are tight.

Step 5: Close and lock the safety gate.

Step 6: Before compressing, check that the shock absorber and spring are secure, and then use the hydraulic handpump to compress the spring.

Step 7: To release the compressed spring, gradually release the pump pressure by turning the pressure knob anti-clockwise.

Tips for safe working

Safety first: Draper Tools recommends that you read and understand the owner’s manual and all the labels affixed to the compressor.

Sensible use: Never compress the spring to the extent that the coils touch, and make sure you don’t leave a compressed spring unattended or compress the spring for a long period.

Keep it clean: Cluttered areas and benches invite accidents. Ensure that your work area is always clear of any hazards.

PPE: Wear CE approved safety goggles at all times when using the spring compressor.