Continental explains to the PMM auidence why the teeth on timing belts in certain engines are prone to damage and what you can do to solve the problem.

Various diesel engines are affected by this problem, including: Opel 2.0; Citroen/ Peugeot 2.0/ 2.2 Blue HDi; Ford 2.0 TDCi / ECO netic / ECOBlue; Toyota 2.0 D4d.

The problem

Teeth are sheared off during the starting process or after a short running time, possibly engine damage.

The cause

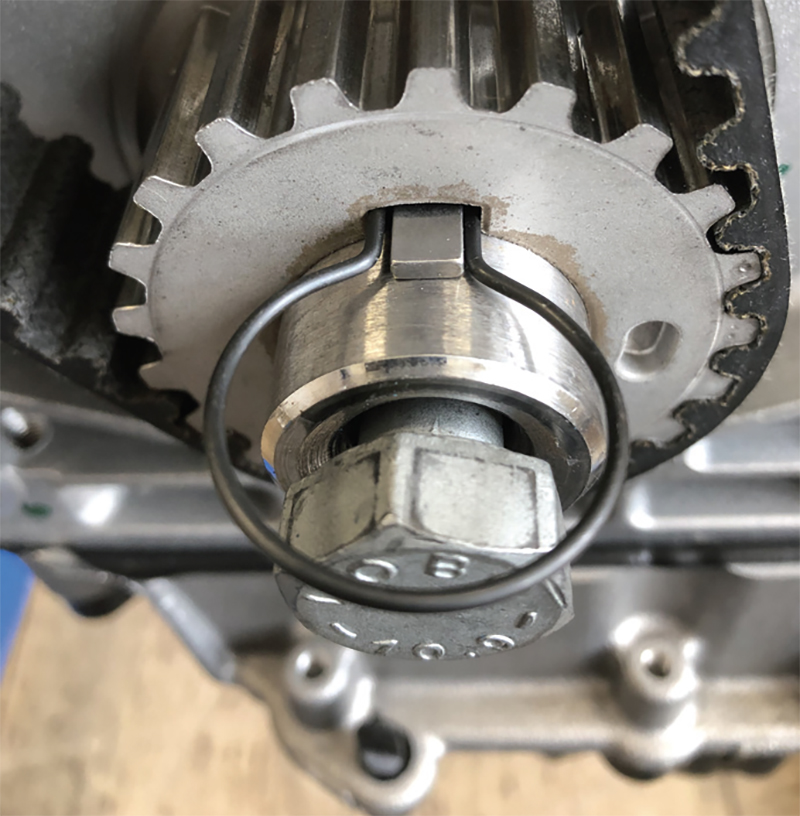

The belt drive is equipped with an oval crankshaft sprocket to reduce power peaks in the belt drive. The crankshaft sprocket is mounted loosely/moveably on the shaft and can be twisted without using the special tool. This, in combination with an incorrectly mounted high-pressure pump, leads to greatly increased force peaks and can cause the timing belt to fail.

When working on the high-pressure pump beforehand, it is essential to ensure the correct installation position.

The camshaft sprocket has two lockingvpoints:

8mm > 1st cylinder TDC for changing thevtiming belt

6mm > approx. 75° further, for disassembly and assembly of the injection pump

The high-pressure pump itself has markings on the pinion as well as on the housing, which must be aligned for correct installation. If the high-pressure fuel pump was removed and installed in addition to the timing belt change, first install the timing belt completely and then the high-pressure pump.

The difficulty is finding the markings. Used pumps are sometimes wetted with black oil on the gear wheel and the special features of this pump are simply not known to many workshops. A sticker on the injection pump indicates that the special installation instructions must be observed.

The solution

If the high-pressure fuel pump was removed and installed in addition to the timing belt replacement, it is essential to ensure the correct installation sequence.

First fit the timing belt completely and then the high-pressure pump. The tensioning process must be carried out according to the vehicle manufacturer’s instructions, using all the special tools intended for this purpose.

When installing the tensioning pulley, make sure that it is seated on the pin and that the tensioning pulley lock is not removed until the timing belt has been installed. The tensioner pulley must be over-tensioned in the first instance and the engine spun four times before the final tension is set (see installation instructions of the respective vehicle manufacturer).