Errors are frequently committed by technicians when attempting a routine timing belt change, so this detailed guide from the ContiTech Power Transmission Group should ensure that the procedure goes smoothly.

The manufacturer recommends inspecting and, if necessary, changing the timing belt and tensioning pulley at 160,000 km.

It is also recommended that you replace the tensioning pulley, idlers and water pump at the same time as changing the timing belt. Although the water pump is driven by a multi V-belt, rather than the timing belt, in this engine the pump is mounted behind the timing belt drive, and the timing belt idler is attached to the water pump. Should the water pump fail later, the entire process has to be repeated using new parts since Ford has forbidden the continued use of used timing belts in this case.

Preparatory work

Identify the vehicle using the engine code and then disconnect the vehicle battery. Do not turn the crankshaft and camshaft once the timing belt has been removed. Turn the engine in the normal direction of rotation (clockwise), unless otherwise specified, and make sure you turn the engine only at the crankshaft pulley and not at the other sprockets. Comply with all VM tightening torques. Jack up and prop the front of the vehicle so that the front engine mount is not under strain.

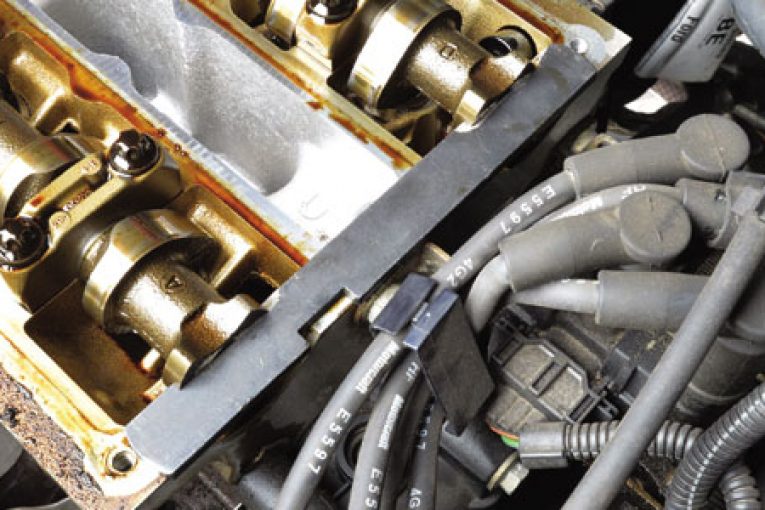

You should then remove the power steering reservoir (don’t detach hoses), ancillary unit belt, coolant expansion reservoir (hoses don’t need to be detached), water pump belt pulley, upper/lower timing covers and front engine mount, making sure you support the engine to do so. The middle timing cover, spark plugs, heat shield, crankcase ventilation system hose and valve cover can also be removed. Make sure you note the loosening order and unscrew items in a cross-cross sequence – from outside to inside.

Camshaft belt – removal

Set the valve timings to the TDC mark of cylinder 1. Locate the camshaft locking tool (303-376) on the camshaft and then insert the crankshaft locking tool (303-574).

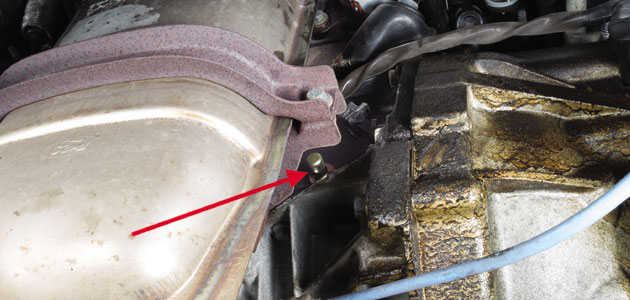

To do so, unscrew the plug from the engine block and screw in the locking tool.

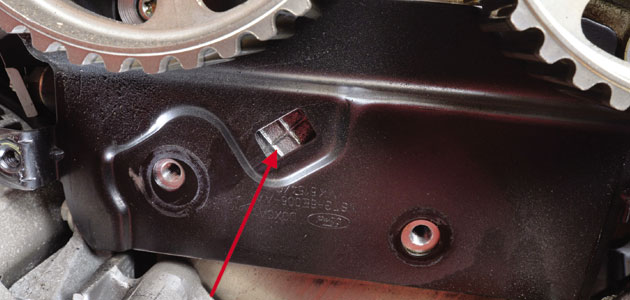

Observe the mark on the crankshaft belt pulley.

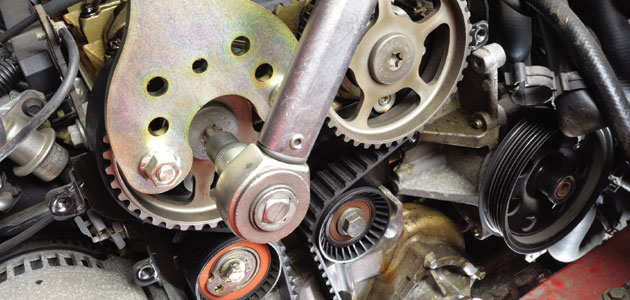

Loosen the tensioning pulley bolt and release the tension in the timing belt/tensioning pulley. To release the tension, turn the tensioning pulley hexagon socket clockwise. Remove the crankshaft belt pulley and the timing belt can now be removed finally.

Camshaft belt – installation

Firstly, loosen the camshaft sprocket bolts; to do this you should use the counterhold (205- 072).

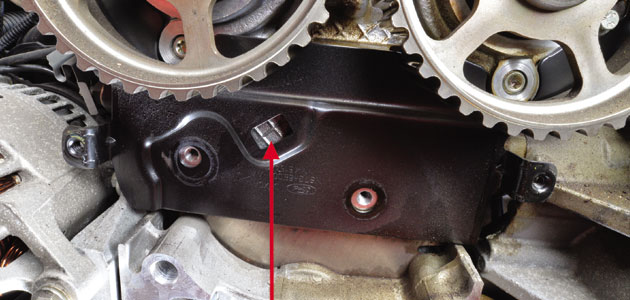

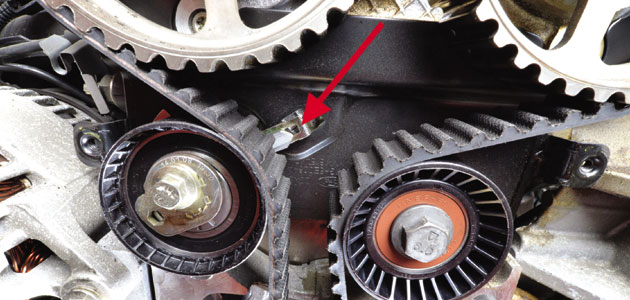

Then check or reset the valve timing settings in the same way as you did for belt removal. Fit the new components, ensuring that the tensioning pulley retaining bracket is correctly seated in the metal cover recess.

Fit the timing belt anti-clockwise, starting at the crankshaft pulley, but take care to ensure that the timing belt isn’t kinked during fitting. You should also note that the timing belt must be tight between the sprockets on the tight side.

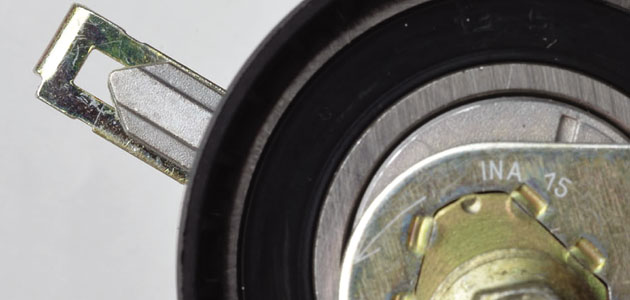

Tension the timing belt anti-clockwise using the tensioning pulley until the tensioning pulley marks are aligned.

Tighten the tensioning pulley bolt to a torque of 25 Nm. Refit the crankshaft belt pulley, making sure you use a counterhold when doing so, and that you tighten to a torque of 115 Nm. Remove the locking tools and tighten the exhaust camshaft bolts to a torque of 68 Nm and intake camshafts to 68 Nm.

Correct valve timings

Turn the engine through two revolutions in the direction of engine travel and set the engine to TDC cylinder 1. Insert the camshaft and crankshaft locking tools. If the locking tool can’t be inserted you should correct the valve timings. Check the timing belt tension again. Remove the locking tools and screw the plug (24 Nm) back into the cylinder block. Remove the holding tool and fit the components in the reverse order of removal.

You should then fit the cylinder head cover (bolts 1st stage: 2 Nm; 2nd stage 7 Nm), spark plugs, upper timing belt guard (10 Nm) and lower timing belt guard (7 Nm), water pump belt pulley (24 Nm), ancillary unit belt, engine mount bolts (bolt(s): 48 Nm; nut(s): 80 Nm), engine bracket bolts (50 Nm) and, finally, the engine mount.

Record the timing belt replacement on the supplied sticker and place this in the engine compartment. Finally, carry out a test run or test drive.

ENGINE CODE: EDDB, EDDC, EDDD RECOMMENDED LABOUR TIME: 2.2 HOURS

Fitters need the following special tools for the procedure:

1. Camshaft locking tool OE (303-376)

2. Crankshaft locking tool OE (303-574)

3. Counterhold OE (205-072)