When replacement of a damaged A/C compressor takes place, the air conditioner has to be flushed to remove harmful remains like metallic chips, dirty oil and dye. Neverth eless a lot of workshops neglect this mandatory work because of additional efforts.

eless a lot of workshops neglect this mandatory work because of additional efforts.

VEMO has analysed this problem and developed a method to flush the A/C circuit easily. With the new flushing supply set (V99-18-0067) this is done cost-effectively, with less work and, above all, without any residues of flushing agents in the system.

Here we look at the process involved:

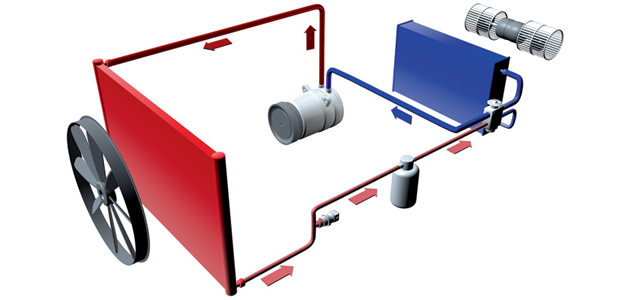

Step 1

Before starting work at the air conditioner, check the flow direction. Principally it should be in the following order: compressor, condenser, drier, expansion valve, evaporator (for air conditioner with expansion valve) or compressor, condenser, orifice tube, evaporator, accumulator (for air conditioner with orifice tube).

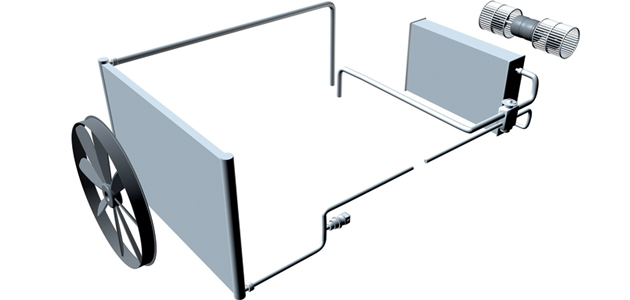

Step 2

Recover the refrigerant from the air conditioner and remove the compressor and drier (for an air conditioner without expansion valve also remove the orifice tube).

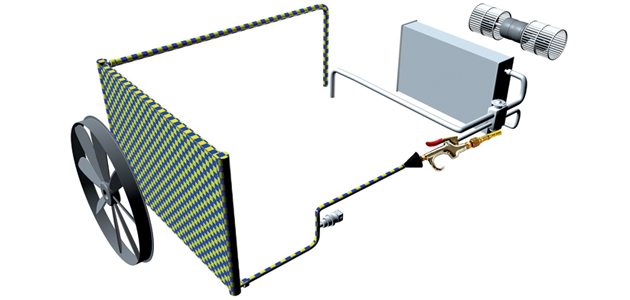

Step 3

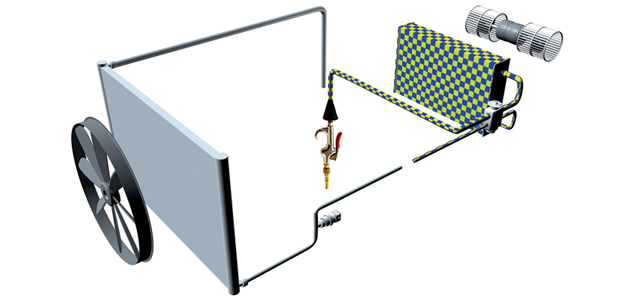

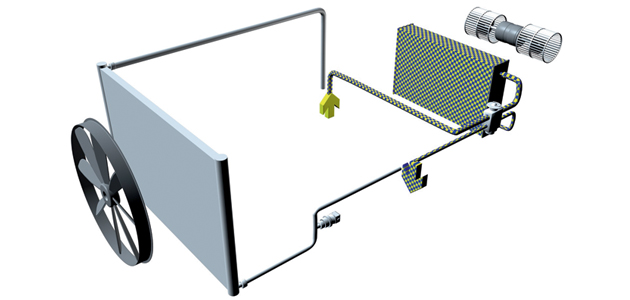

Prepare the VEMO air conditioner flushing supply set V99-18-0067 by installing valve, hose and flush gun on the can. Inject the flushing agent with the pressure in the can. Flush against the flow direction.

Step 4

Follow the flush with compressed nitrogen or pressurised air (at 8 bar/120 PSI max.) to increase mass flow for maximum cleaning to finally exit the system with the dirt.

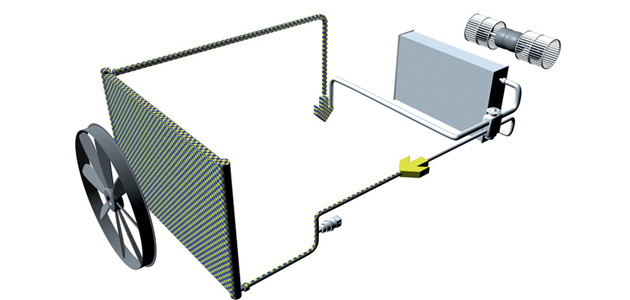

Step 5

Repeat the procedure for the next part of the line. The amount of flush needed to adequately clean and flush will vary due to the length of the line to flush. An approximate value would be 50% of the can for the condenser side and 50% of the can for the evaporator side. Exact instructions are listed in the product manual.

Step 6

VEMO recommends installing an in-line filter to avoid problems with residues which are left in the system as a hazard. Pull a vacuum after assembly to remove any residual solvent. The line set is clean and ready for service.

Want more technical advice? Find out how you can avoid A/C compressor failures by clicking here