Noisy secondary air pump? Why do speed fluctuations occur on cold engines? What is the cause of the diagnostic trouble code P0410 and P0411? Here, the technical experts at MS Motorservice explain why you should check the actuating electric switchover valve and the secondary air valve.

The following customer complaints can occur during the cold-running phase in vehicles that have a secondary air system:

- Secondary air pump (SLP) makes noises

- SLP does not work

- Repeated failure of the SLP after a brief running period

- Variation in revs when the engine is cold

The possible OBD error codes for this situation are likely to be P0410 and P0411.

The trigger for this damage can remain in the vehicle and lead to the recurrent failure of the secondary air pump. When replacing the secondary air pump, the electrical reversing valve and the secondary air valve must be inspected for leaks as a basic principle.

Under inspection

The secondary air valve can be quickly inspected very easily:

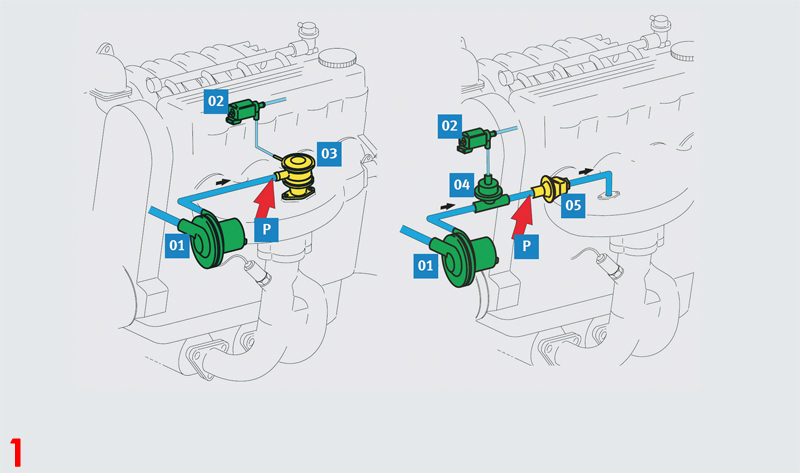

- Loosen the connecting hose on the secondary air non-return valve leading to the secondary air pump. See inspection point ‘P’ in Fig 1

- If there are deposits on this side of the valve (finger test – see Fig 2), the non-return valve is leaky and must be replaced. In that case, the secondary air pump may already have been damaged

- Inspect the secondary air pump and replace it if necessary

In almost all cases the damage is caused by exhaust gas condensate in the secondary air pump. In repairs, often only the secondary air pump is replaced.

Different designs

Secondary air valves are an integral part of the secondary air system. They are fitted between the secondary air pump (Fig 1.01) and the exhaust manifold.

They prevent pressure peaks in the exhaust flow from damaging the secondary air system and exhaust gas or condensate from entering the secondary air pump.

There are different designs of secondary air valves. Switch-off non-return valves (Fig 1.03) are generally vacuum-operated valves, whereas later designs (from approximately 1998) are opened by the pressure of the secondary air. This does away with pneumatic control by an electrical reversing valve (Fig 1.02). Secondary-air non-return valves (Fig 1.05) open as a result of the pressure of the secondary airflow.