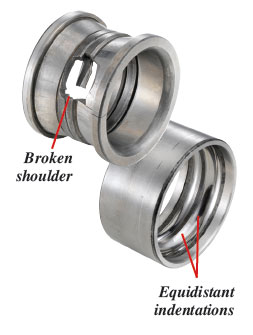

1. INDENTATIONS OR BREAKAGE OF THE SHOULDER DUE TO INCORRECT FITTING

EVIDENCE

■ Presence of indentations located on the edge of the track and often seen over the complete circumference of the ring.

■ The indentations are in line with the position of the rolling elements.

■ Damaged or broken shoulder.

■ A slapping noise to the assembly.

CAUSES

■ The bearing was off-centre when fitted.

■ The bearing fitting was incorrect.

■ The bearing was dropped onto a hard surface.

■ The bearing tightening load was transferred through the rolling elements.

EXPERT ADVICE

■ To avoid damaging the bearing, do not apply load on the inner ring.

■ Follow the general fitting recommendations.

2. SCRATCHES ON SUCCESSIVE BALLS FROM AN UNTIGHTENED DRIVESHAFT

EVIDENCE

EVIDENCE

■ Damage with circular grooves deforming the surface of the balls.

■ Grooved scratches, similar to ‘petanque’ balls.

■ Matching damage on the bearing tracks.

CAUSES

■ The vehicle was moved without the driveshaft or hub nut in place (such as when being serviced).

■ Damage on the balls from contact and rolling on the inner edge of the track, due to a gap between the inner races.

EXPERT ADVICE

■ Avoid moving any vehicle when the driveshaft nut isn’t tight.