With an increasing number of GDi engines rolling through garage doors over the next decade, Carwood gives some expert advice on how to deal with an old service issue – carbon build-up.

In a traditional multi-point or port fuel injection engine, fuel is injected into the intake port of each cylinder, where it washes over and cleans the intake valves. In a gasoline direct injection (or GDi) engine, however, the fuel is injected at high pressure directly into the combustion chamber of each cylinder, bypassing the valves. Subsequently, small amounts of dirt, carbon and other particles from the air intake and crankcase ventilation system can build up and burn onto the intake wall; over time this leads to carbon deposits on the valves, cylinder head inlet ports and injectors, which can cause a number of issues:

- Intake valves: carbon deposits on or around the valves can disrupt airflow, creating turbulence and an uneven air-fuel mix. This can cause noticeable power loss and drivability issues such as misfiring. The resultant rich and lean mixtures can also generate hotspots within the combustion chamber, causing localised areas of carbon to overheat, and in turn engine knock and reduced engine efficiency

- Cylinder head inlet ports: deposits here can cause pre-ignition, rough starting, and rough idling, as well as foul spark plugs and misfire codes

- Injectors: fuel that is left in the injector tip after engine shutdown will get ‘cooked’ with the residual heat. Deposits on the tip will hamper fuel delivery, causing the engine to run lean and with it issues such as increased emissions. Since GDi injectors are reliant on fuel to cool the nozzle assembly/tip during operation, any restrictions can also cause the nozzle tip to overheat and deform.

Symptoms to ask customers about

The effects of carbon build-up are gradual, and often subtle to start, so keep an eye out for:

- Reduced acceleration/power

- Rough idle/hard engine starts at cold

- Engine misfires

- Excessive engine ping on acceleration

- Lower fuel economy

- Black exhaust smoke under hard acceleration

- Cylinder misfire fault codes from one or more cylinders

- Check engine light

- Faulty sensors from fouling

If you suspect carbon build-up, conduct some simple tests to confirm the diagnosis:

- Use a diagnostic scan tool to check for random and single cylinder misfire or cylinder disabled code

- Remove the intake manifold and inspect the cylinder head intake runners for carbon deposits on the walls and back of the valves. Check the injectors too

- Connect a pressure transducer to the intake manifold whilst cranking the engine – low vacuum on the intake stroke in at least one cylinder is a sign that the intake may be partially blocked with carbon

How to remedy carbon build-up

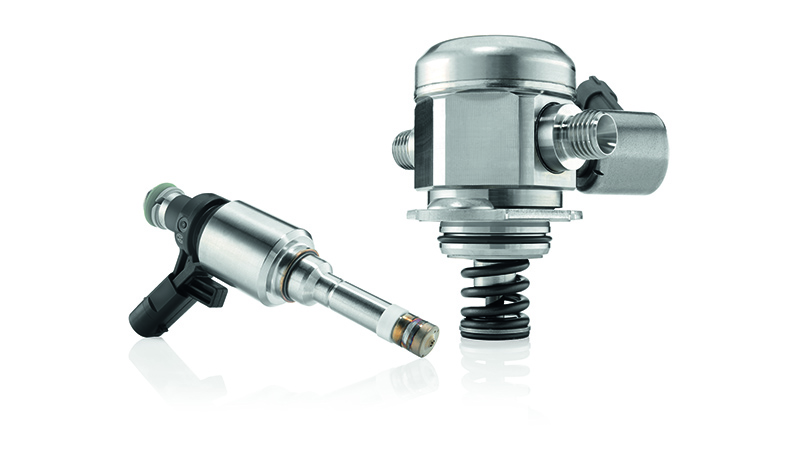

The only way to resolve carbon build-up is to remove the intake manifold and blast the intake runner and valves with a non-abrasive media. Technicians should also remove the injectors and perform off-vehicle diagnostic tests and specialist cleaning on a specialist GDi bench. Carwood has invested in this capability and can offer both injector diagnostics and servicing, and a full range of Bosch OE GDi pumps and injectors, backed by expert technical support, should parts need replacing.

So, by understanding the problems, and knowing how to avoid and fix them, service professionals can take advantage of another lucrative service opportunity and build up both their sales, profits and customer loyalty.