Simple steps to identifying a defective component.

Nowadays, almost all vehicles have an on-board diagnostic,which records faults in the vehicle and stores the possible causes in a fault code memory.

Reading out the diagnostic trouble code (DTC)

You should firstly read out the fault code memory which can be achieved by using any OBD-compatible engine tester. The OBD detects a malfunction, but doesn’t always identify the actual cause. Prior to installing a new air mass sensor you should, therefore, check the old sensor first.

Checking the voltage supply

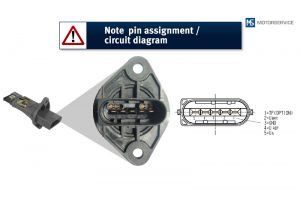

Make sure you note the pin assignment of the air mass sensor and the vehicle’s circuit diagram

(see below).

The check can be carried out with a voltmeter, an oscilloscope or using the appropriate engine tester functions (see below).

If no special testing cable is available, the measuring instrument can be connected to the back of the plug using corresponding test tips. In doing so, be careful not to pierce the lines as water could penetrate and lead to corrosion of the lines. You should also make sure that the gaskets in the plug aren’t damaged. When the ignition is on, there should be an on-board voltage of approx. 12V between Pin 2 and the vehicle ground (see below).

Alternatively, the on-board voltage may also be measured between Pin 2 and Pin 3. There is also a sensor voltage of approx. 5V between Pin 3 and Pin 4.

If these values aren’t reached, all affected lines and plugs must be checked for short circuits, interruption and transition resistances.

Checking the output voltage with still air

While the engine is stopped, the output voltage between Pin 3 and Pin 5 is approx. 1V. If the measurement is falsified by a draught, both ends of the measuring tube should be closed using suitable means.

Measuring under load (idling/accelerating)

Start the engine. When the engine is at operating temperature, you should obtain a measurement of 1.2 to 1.8V. During a burst of throttle up to the maximum governed speed, 3.6V to 4.4V must be reached (see below). An oscilloscope is more suitable for this measurement, as it reacts less sluggishly than

the multi-meter display.

If the measured values have been reached, the air mass sensor is OK and another area must be investigated for the fault. This could be impurities in the intake air, soiled/incorrect air filters, or leakages in the intake air system, for example.

In addition, stuck intake manifold flaps, stuck EGR valves, or deposits on the throttle valve can cause the signal from an intact air mass sensor to deviate from the calculated set-point value, causing an entry in the fault code memory (see below).