PMM ’s quasher of quandaries, Ben Johnson, rebuffs the naysayers and elects to keep things simple in the swap shop.

In the world of modern diagnostics, it’s easy to get lost in the maze of systems, modules and communication networks that drive today’s vehicles. The BMW X5 M50d is no exception. Loaded with advanced features like adaptive cruise control, night vision, and pedestrian protection, it’s a marvel of modern engineering – until a seemingly minor issue brings the entire system to its knees. And I do mean knees, because when you’ve got no anti-lock brakes, you’ll be doing plenty of praying.

This month, I encountered just that: a €60 wheel speed sensor on the front left of an X5 that disabled a host of critical functions. You’d expect a sensor malfunction to affect the DSC (Dynamic Stability Control) or ABS, but what surprised even me was the ripple effect it had on systems entirely unrelated to braking. Suddenly, the night vision system went dark – no more spotting deer at midnight – the adaptive cruise control stopped functioning and of course, the ABS/DSC system threw in the towel as well. I couldn’t help but wonder if a faulty cup holder was next.

The Culprit: A simple wheel speed sensor

Now, you’d think the wheel speed sensor would be a bit more considerate (Fig.3). It’s not exactly a premium part, and you wouldn’t expect it to have delusions of grandeur. But there it was, a humble €60 part, punching well above its weight, managing to incapacitate half the vehicle with the efficiency of an overzealous bouncer at a nightclub – one minute everything’s running smoothly, and the next, you’re out on the curb wondering what just happened. And all this because it couldn’t measure the speed of a wheel. For the uninitiated, the wheel speed sensor is responsible for sending data about the wheel’s rotation to the DSC unit, helping the vehicle maintain stability. But when this sensor fails, things escalate quickly – and not in a good way.

The CAN bus domino effect

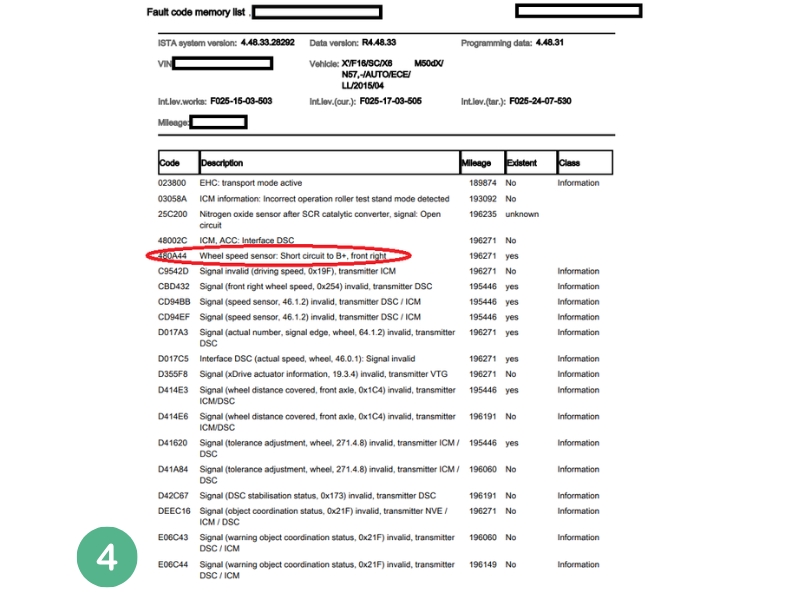

Most technicians are aware that modern vehicles rely on CAN bus networks to relay information between different control units. In an ideal world, each system communicates flawlessly, and the car operates like a well-oiled machine. However, in this case, our €60 part decided to stop sending wheel speed data, and, predictably, the entire car threw a tantrum. Systems that depend on accurate speed data, like adaptive cruise control and night vision, were forced to disable themselves – because when in doubt, just give up (Fig.4).

What we saw was a classic case of the “CAN bus domino effect,” where missing messages from one component lead to confusion across the vehicle network. Control units don’t guess when critical messages are missing or substituted. Instead, they simply shut down. Without the accurate feedback they need, they can’t operate as part of a coordinated system. As a result, any functions that rely on this information grind to a halt, leaving systems that depend on each other stranded and unable to perform. It’s like playing a game of Chinese whispers, but instead of ending with a funny phrase, you lose your brakes – well, kind of.

A clever (and simple) fix

A few years back, I put together a simple LED test box with a pull-up resistor specifically for diagnosing wheel speed sensors. The beauty of this tool was that it eliminated the need to scope milliamp currents on active wheel speed sensors in a cramped wiring harness, saving valuable time. However, in this particular case study, there wasn’t even a need to break out the LED test lamp. I am a believer in keeping things extremely simple when needed and adapting to more in-depth diagnostic approaches when the time calls for it – this particular job didn’t call for such complexities.

For some, diagnosing this issue without the right mindset could have been an endless exercise in complex diagnostics, running test after test with sophisticated tools. In fact, the vehicle had already been to another specialist, who was sharpening their CAN bus troubleshooting tools, ready for a deep dive into the vehicle’s electronic abyss. Meanwhile, I was sipping tea, wondering if perhaps they were overthinking things.

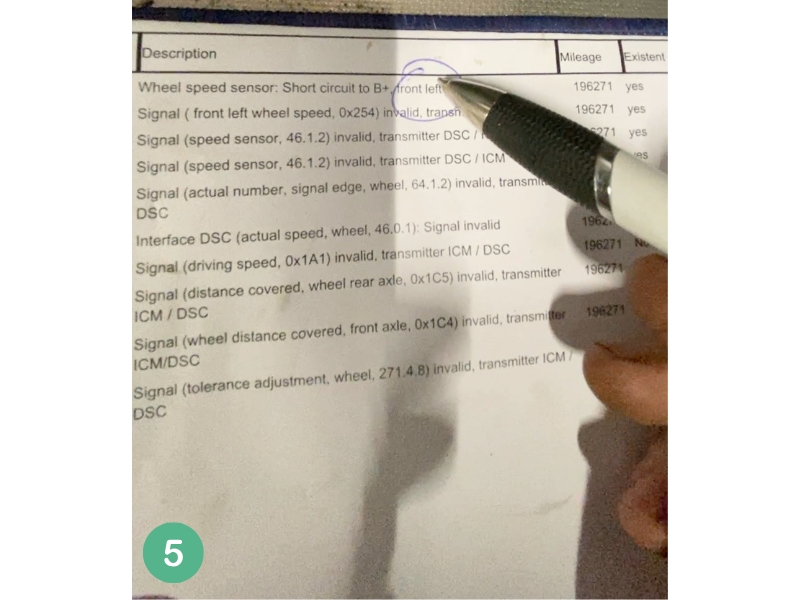

Instead, I went for a much simpler approach: I swapped the suspect sensor from the front left to the front right. No fanfare, no parade, just a quick swap. As expected, the fault moved with the sensor, confirming it as the culprit (Fig.5). With that quick swap, I had my diagnosis in hand, and a replacement was ordered and installed. The X5 was back to its happy, electronically stable self. A €60 sensor had caused a whole system shutdown, and the fix was as quick as a coffee break.

Lessons learned: The state of modern diagnostics

We are at a critical juncture in the evolution of our industry. The skill set required to be an effective diagnostic technician is fading fast, and in its place, we’re seeing a lot more of what I like to call ‘showmanship.’ You know the type – pulls out every tool in the book, calibrates this, recalibrates that, but when it comes down to it, couldn’t spot a bad sensor if it bit them. It’s all flash and no substance.

I’ve worked with all the fancy diagnostic tools – oscilloscopes, measuring instruments, you name it – but part of being a skilled technician is knowing when to use them and when to leave hanging up on the tool rack. Sometimes, the simplest fix is the best one. A real technician can see through the noise and know when to keep things straightforward. And let’s be honest – if you can solve a problem with a cup of tea in one hand and a ratchet in the other, why complicate it? (Fig.6)

TikTok comment: “Medieval” approaches get the job done

Now, speaking of keeping things simple, someone on my TikTok recently commented that my approach to checking a wire with a halogen bulb was, and I quote, “medieval.” Personally, I think it’s a bit harsh. I mean, if it’s medieval, at least it’s better than the stone age, right? But in all seriousness, my “medieval” method worked faster than the average master technician would have with their high-tech gear. That’s the point – sometimes the old ways work better. I’m not saying I’m about to bust out a jousting lance next time a BMW rolls in, but if a method works, it works.

That said, I’ll give credit where it’s due. I’ll admit, I’m not immune to modern advancements, and I’ve decided to invest in a Load Pro to improve efficiency. Even I can evolve – though I’ll still keep my trusty halogen bulb handy, just in case someone wants to question my medieval ways again.

This whole experience with the sensor drives home a few key lessons about modern vehicle diagnostics. First, in the age of interconnected systems, one minor fault can cause chaos. The more integrated and complex the car, the more systems rely on a single sensor for accurate data, and the greater the likelihood of a failure affecting seemingly unrelated systems.

Second, it’s a reminder to go back to basics. While it’s tempting to rely on complex diagnostic equipment, sometimes the simplest approach – like swapping sensors – can lead to the quickest solution.

Finally, it’s a testament to the importance of understanding the vehicle’s communication networks. The real problem here wasn’t just the sensor failure itself, it was the missing or incorrect CAN bus messages it caused. Understanding how these systems interact allows us to see the bigger picture and, ultimately, resolve the issue efficiently.

As vehicles become more advanced, the number of potential failure points increases. But with a good understanding of how CAN bus networks work and a bit of old-fashioned ingenuity, it’s possible to avoid getting lost in a diagnostic rabbit hole. One sensor might be a small part, but its impact can be massive, as this BMW proved.