The Reman Mission

Once they arrive with the ACtronics technical team, most ECUs are reconditioned with new original components (such as semi-conductors, chips and sensors). When rebuilding a Mercedes A-Class ECU, for example, original sensors are placed together with professional calibration equipment to ensure the end product is equivalent to a new ECU, at a much more affordable price.

Where the original board of the ECU is damaged so badly that a repair is virtually impossible, ACtronics will either replace the entire board with a complete ‘in-house’ developed and manufactured board or a completely new replacement ECU unit.

Guaranteed extended life

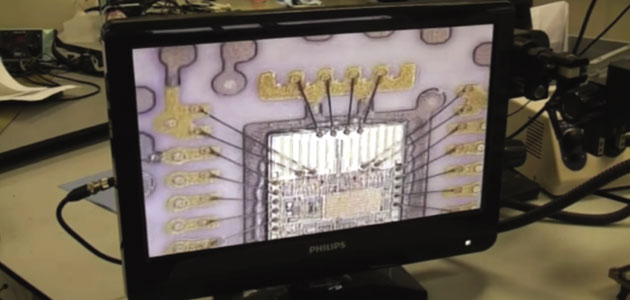

The company can also rebuild a ‘hybrid’ ECU using advanced computerised tooling. A hybrid ECU describes a unit that utilises a circuit board that consists of a ceramic plate. ACtronics will renew all hybrid connections automatically and, because multiple connections are made on each contact area, an extended life can be guaranteed.

In order to detect a defect in the vehicle’s ECU, and to ensure that the repair has been successful, ACtronics has designed and developed three in-house ECU testing machines. These machines are capable of communicating with the latest CAN, LIN and J1850 bus networks. In addition, the ECU testing software is so sophisticated that during the final tests the ECU’s anti-theft system unlocks.

The old silicone gel is removed using a specially developed bath of chemicals.

The Bare Die connections are visually inspected and hybrid connections removed.

The aluminium and gold wire connections are made with an automatic ultrasonic bonder.

New connections for ALL hybrid connections and damaged Bare Die connections are created.

The unit is filled with a ‘high specification’ silicone gel.

A new cap is assembled and fitted.

The ACtronics Vision 5 unit then fully tests the ECU using an automated script.

The unit is then returned to the garage.