Timing belt replacement guide on a 2013 Skoda Fabia, Monte Carlo Engine: 1.6 TDi, 16-valve (engine CAYC) following issues with timing belt noise.

Following a timing belt kit installation, a Skoda Fabia was returned by a customer in the North East of England less than two weeks later. The complaint concerned an unacceptable ‘whining’ noise from the engine.

In such cases, probable causes generally include: High belt tension, low belt tension, misalignment, bearing issues, pulley wear/damage, belt wear/damage.

The local motor factor was advised that the garage planned to install a second belt kit and register a claim because of a ‘faulty pulley’. This was part of a Gates PowerGrip belt kit that the motor factor had supplied. Although all parts are covered by the standard Gates warranty, the motor factor was concerned that a basic installation error could be about to be repeated.

Isolating the noise

The first task was to isolate the source of the noise and to establish a link with the timing belt drive. To rule out the accessory belt as the source, the engine was run at heavy load. Headlights, rear window heater and the air conditioning system were all switched on in sequence. There was no change in the volume or pitch of the noise. This confirmed there were no accessory belt issues.

Identifying the cause

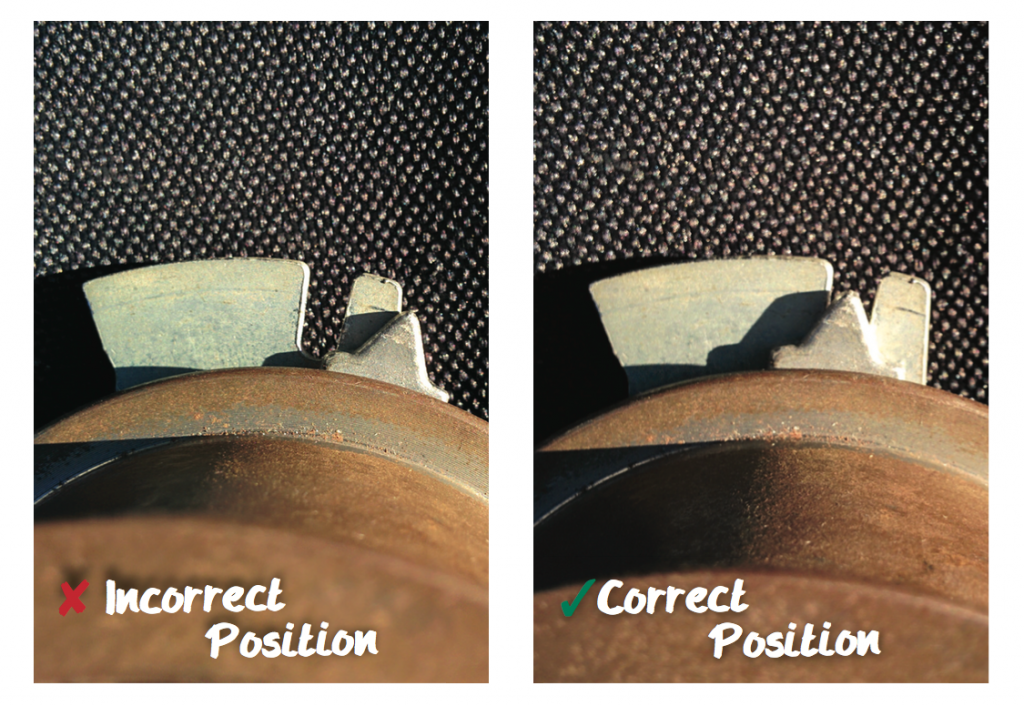

When the engine had cooled down, and after removing the timing belt cover, it was observed that the pointer was incorrectly aligned towards the high-tension side (it is normal for the pointer to be out of the window, towards the hot stop, after revving up the engine). The noise was more likely to be caused by the belt, rather than any of the pulleys. The tension of the belt had been set too high.

Tension must be set precisely. Re-setting the tensioner allowed the pointer to line up correctly. Once the engine was re-started, it was clear that the cause of the noise had been cured. However, this was not to be the end of the story.

Initial tensile decay

After the engine reaches full operating temperature, initial tensile decay of the belt takes place. This is a process of initial change caused by:

■ Compression of textiles used in construction

■ Slight variations in tension between the internal cords

■ Belt teeth settling on the pulleys

Once belts reach full operating temperature, textiles are compressed, variations in cord tension have been equalised and the belt teeth have ‘bedded’ themselves into position.

The tension setting procedure is very precise and allows for initial tensile decay. Consequently, if a timing belt is installed for a second time, initial tensile decay has already taken place. Even if the tension of the used belt is re-set according to the manufacturer’s recommendations, correct tension can never be achieved. So, even if the needle sits in the middle of the window, the belt is over-tensioned. Remember, initial tensile decay takes place only once. This is the reason why used timing belts must never be re-fitted.

A new belt

Before the vehicle could be returned to the customer, it was essential to fit a completely new belt to ensure correct tension was achieved. Failure to do so would have led to premature timing belt failure and, very likely, catastrophic engine damage.

False positives

The motor factor’s concerns were well founded. It is a common assumption that new pulleys are likely causes of most noise issues that arise after a scheduled belt replacement. In fact, the most common causes are installation issues. The chances are, this basic tensioner setting error would have been repeated.

However, if the mechanic had taken extra care to set the tensioner correctly this time around, the noise problem would have been fixed. Moreover, the garage would have been satisfied that the pulley had been faulty. The motor factor would have had a major problem because the manufacturer’s examination would have confirmed that its construction of the pulley was ‘sound’. The garage would have been very surprised to learn that the claim had not been upheld.