Best practise guidelines from European Exhaust & Catalyst on forced DPF regeneration.

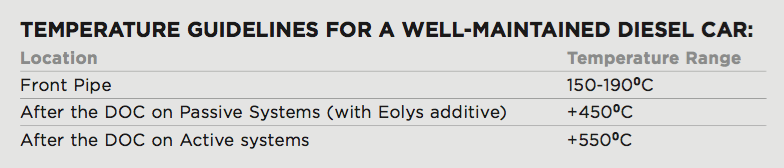

When a DPF reaches a pre- determined particulate matter (PM) fill level (around 40%), the ECU will activate the regeneration process, which can inject up to eight times more fuel per stroke – a rate which is needed to produce temperatures in excess of 550°C dry or 450°C with the passive system (fuel additive Eolys), so that it can incinerate the PM that has been captured within the DPF.

The regeneration process will not reach a conclusion if:

- The engine management light is illuminated for any fault

- There is less than 20L of fuel in the fuel tank or if the fuel light is on

- The pressure sensors are not working correctly

- The pressure sensor pipes are damaged – check for degradation under heat shielding

- The EGR system is not working correctly

- The engine oil is the incorrect specification for the vehicle – must be Low Ash grade. Check the engine oil for diesel contamination (could be the result of regeneration)

- The fuel additive, Eolys, level is too low

In order to carry out a forced DPF regeneration, the correct diagnostic or reset tool must be used. This operation could take up to 30 minutes. Ensure the regeneration process is conducted in a safe environment as exhaust temperatures will be very high.

Filters require more maintenance than catalytic converters. Engine oil ash builds up on the surface of the inlet face of the filter, and will eventually clog the pores. This increases the pressure drop over the filter, which, when it reaches a totally clogged state, is capable of causing engine damage. Regular filter maintenance is therefore a necessity.

If the DPF is not regenerated and the PM level fills to over 90% or 45g, the DPF will need replacing. This is not covered under warranty. When fitting a new DPF, the ECU must be reset before completing a forced regeneration. This is to ensure that the ECU knows that the DPF and all related sensors are reset to empty.

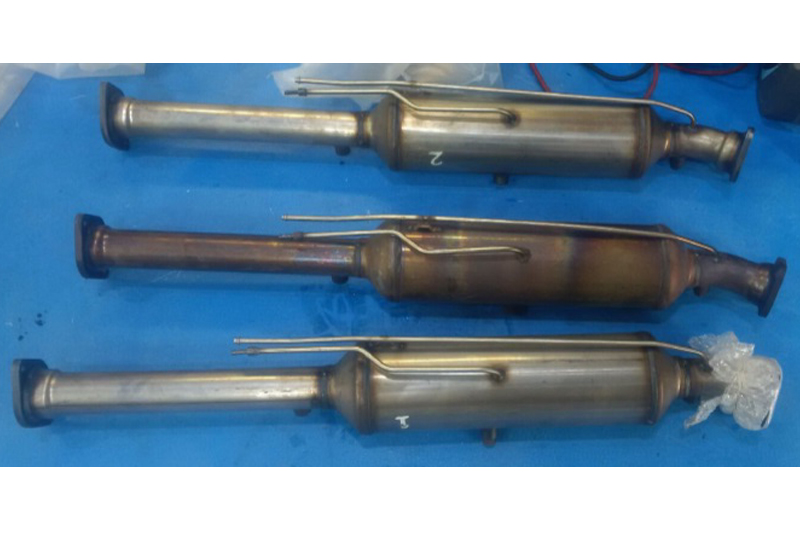

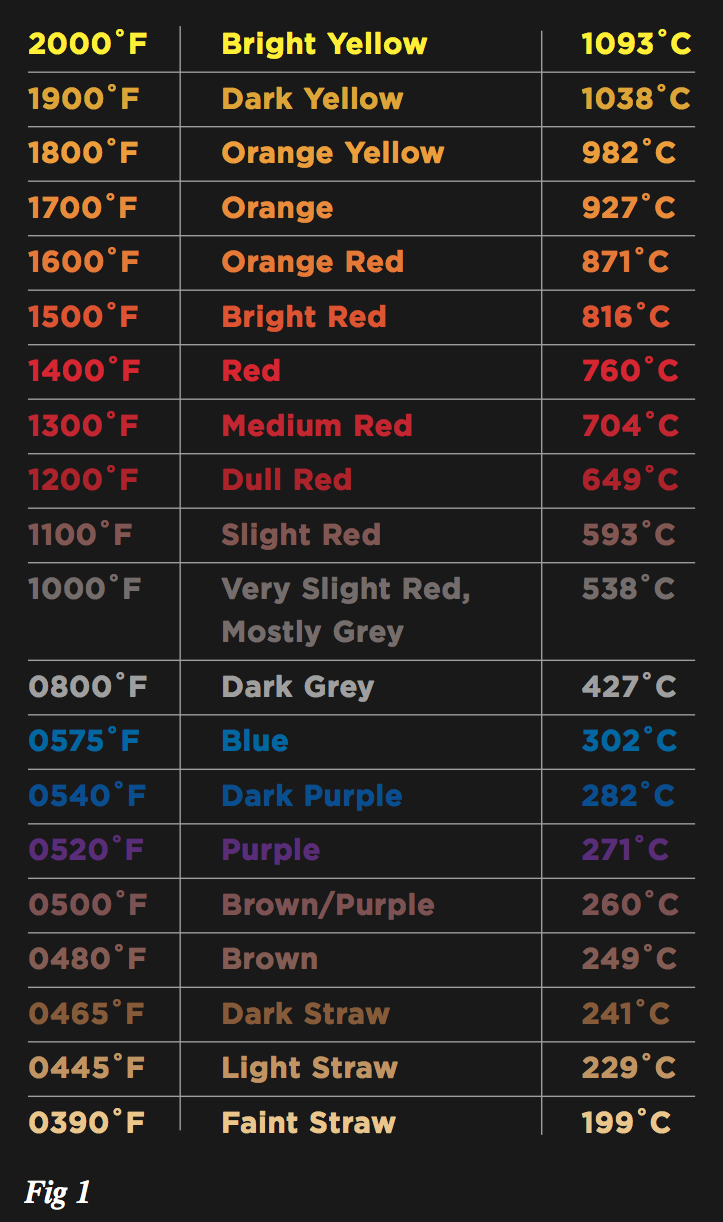

When fitting a new DPF, it is important to reset the ECU and carry out a forced regeneration. After this operation, it is advisable to look at the DPF and pipework to make sure this process has been completed. If regeneration temperatures have been reached, the steel will discolour to a ‘Dark Straw’ or ‘Brown’ colouration (as shown in the DPF colour chart in Fig 1). This is important as some tools are known to indicate that indicate that regeneration has occurred. The colour chart is a reasonable guideline for steel discolouration. Fig 2 depicts three DPFs. The steel discolouration indicates that the middle DPF has reached regeneration temperatures.