After designing a specialist tool to aid in cleaning a vehicle’s cooling system, Meyle explains how this new piece of equipment can help with the flushing process.

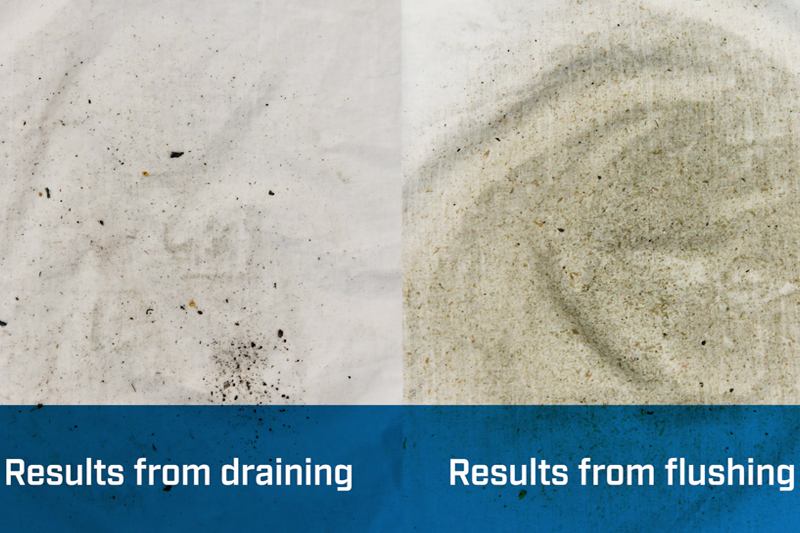

Thorough and regular flushing is one of the decisive steps in the maintenance of cooling systems. Contamination, e.g. due to the incorrect use of sealing compound in the cooling system, reduces the cooling capacity in the long run, and can lead to premature failure of the water pump mechanical seal.

However, even beyond this, proper flushing of the cooling circuit is the basis for a longer engine service life. Flushing should take place at the very latest when the water pump is replaced in order to remove particles that can be caused by corrosion or limestone.

To help with this process, Meyle now supports workshops with a specialised tool. With this tool, the cooling system can be cleaned with the aid of water and compressed air – without aggressive chemicals and cleaners.

To explain how this tool can help, Meyle describes how the engine cooling circuit can be cleaned in five simple steps.

Step One – Preparation

The engine must be completely cooled before starting. The old coolant should then be drained and the coolant expansion tank cleaned or replaced if heavily soiled. For environmental reasons, it is important to dispose of the waste liquid properly.

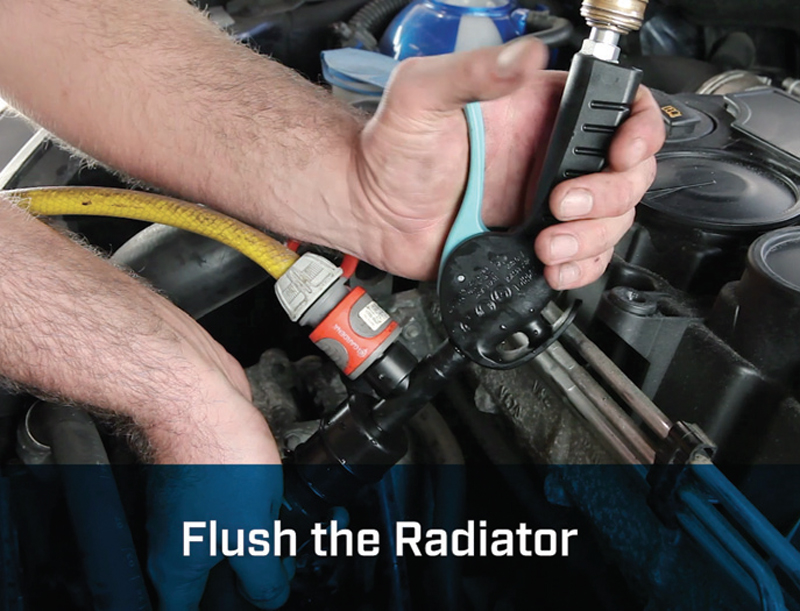

Step Two – Flush the cooler

Remove the upper and lower radiator hoses on the radiator. The lower radiator hose should be thoroughly rinsed from bottom to top for about two minutes with the radiator cap closed using the Meyle tool. Administer short pulses of air into the system to increase effectiveness. The upper radiator hose can then be flushed from top to bottom until the outflowing water is clear and deposits have been removed.

Step Three – Flush the engine block

Next, remove the radiator hoses. Using the Meyle cooling circuit flushing tool, the upper radiator hose should be thoroughly flushed until the outflowing water remains clear and any deposits have been removed. For this step, it is also the case that short pulsating air blows increase the effectiveness of the rinsing process.

Meyle workshop advice: If the thermostat blocks proper rinsing, it must be removed for rinsing. In this context, the company recommends a general replacement of the thermostat.

Step Four – Flush the heat exchanger

If possible, the circuit to the heat exchanger should also be flushed until the outflowing water is clear. As a general rule, flushing the radiator, engine block and heat exchanger removes deposits of corrosion, limestone and silicone seal residue from the cooling system. These can accumulate over many years and permanently impair the functionality of the system.

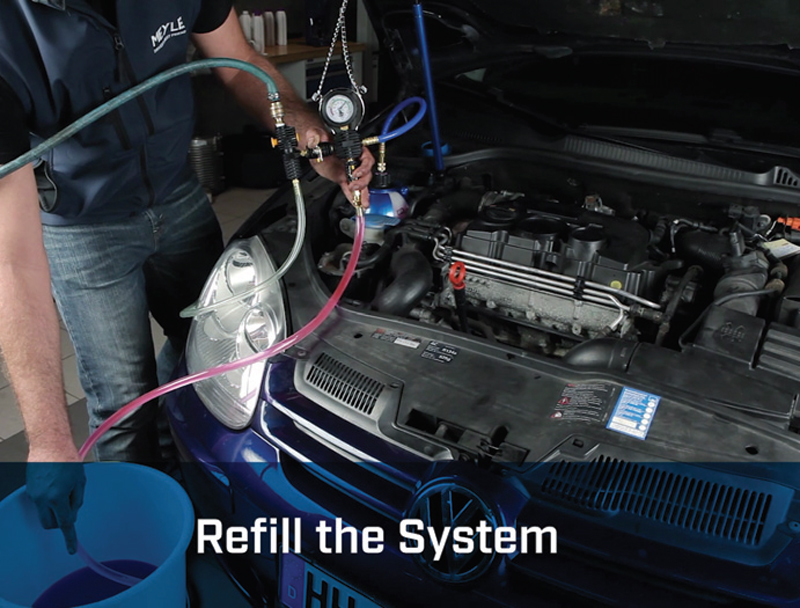

Step Five – Refill the system

In the final step, all hoses, the drain valve and the thermostat should be reattached. You must check whether all necessary connections have been made again. The cooling system can then be refilled with the coolant specified by the manufacturer. The mixing ratio should, for example, be checked with a refractometer.

Finally, the system should be properly vented. A final check ensures that there are no leaks.

Note: Disassembly and installation must always be carried out by trained personnel. Please follow the instructions of the vehicle manufacturer exactly.

Meyle water pumps

All Meyle-HD and the majority of all Meyle-Original water pumps contain a wear-resistant SiC/SiC mechanical seal, and a robust water pump bearing, which increases the reliability of the component. This allows the company to offer a 100,000-mile guarantee for all its water pumps, and a four-year guarantee for MEYLE-HD water pumps. The guarantee does, however, require the cooling system to be flushed before installation.

Meyle TV

All steps to the process outlined in this article can also be followed on the company’s YouTube channel in a short video tutorial. This shows how to clean the engine cooling system cleanly and safely with the Meyle cooling circuit flushing unit. This ensures that all components of the flushing circuit, such as the water pump, function continuously and reliably.