SMPE look at some common failures associated with EGR valves.

The EGR valve feeds a proportion of the exhaust gas back into the engine inlet in a controlled and regulated way. This is to reduce the Nitrogen Oxide (NOx) levels at the combustion stage, in order to improve emissions. When the air/fuel mixture is burnt, the formation of NOx increases as the temperature rises. Recirculating a proportion of the exhaust gas back into the air/fuel mixture lowers the combustion temperature in the cylinder, reducing the rate of NOx formation.

The design of EGR systems has developed significantly since their introduction. They originated as crude jet systems, followed by more accurate vacuum controlled valves, through to modern EGR valves which feed the inlet with exhaust gas in an electronically- controlled way.

Common failures

The most common cause of failure is excessive carbon build up inside the EGR valve and cooler. This is unavoidable over a long period of time, but is significantly increased with repeated short journeys, especially at low speeds. Blocked or partially blocked Diesel Particulate Filters (DPFs) compound this issue. The valve position signal to the ECU has to be very accurate; any wear in the sensor is detected by the ECU and will cause a warning light to be displayed. The vacuum diaphragm for the cooler bypass is prone to failure, as well as external leaks from the cooler as a result of faulty seals.

Symptoms and diagnosis

A faulty or clogged EGR valve can affect the vehicle in a number of ways. A reduction of power due to the valve sticking open or not opening correctly, poor or jerky acceleration, and noticeable decreases in fuel economy, can all indicate an EGR problem. Difficulty starting and uneven idle speed can also be a symptom, while increased smoke from the vehicle’s exhaust may also occur.

A faulty cooler will cause the coolant level to reduce in the expansion tank and may show itself as drips beneath the car, white smoke from the exhaust or overheating. If the bypass is stuck, cold starting may be extremely difficult or emissions may be affected, causing the emissions light to come on.

EGR replacement

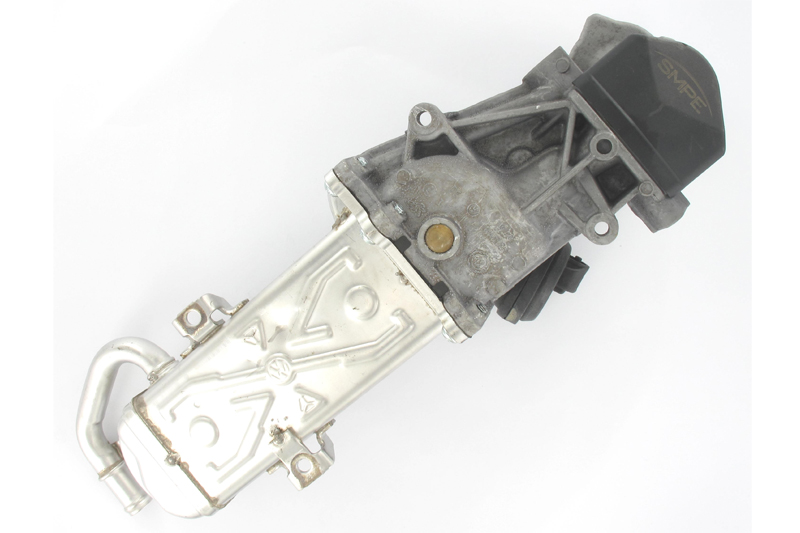

SMPE offers a comprehensive range of EGR valves to cover the majority of vehicles on the road. From the early vacuum type valves through to the latest sophisticated electronically actuated valves, the range covers most popular applications. The company also offers EGR cooler units for some vehicles, where the cooler unit can be replaced separately, reducing the cost of replacing the complete EGR unit.

The parts supplier has developed a solution to the common VAG EGR valve/cooler problem. Its remanufactured EGR valve includes a custom in-house designed PCB and all components are stripped, cleaned and replaced if necessary. Every unit is fully calibrated after remanufacture and includes an individual test certificate. Also included is a set of new gaskets and fitting instructions.