Steve Scott spends his working life on the road as a mobile technician, solving the diagnostic problems that others can’t. In his debut article, Steve recounts a recent case where his tried and tested process enabled him to uncover a faulty ABS module on a Peugeot 207.

Meet Steve

I started Simply Diagnostics three years ago, focusing purely on troubleshooting and auto electrics. I don’t do servicing, maintenance or repairs. With the constant customer scrutiny, bad weather and traffic, being a mobile diagnostician is a difficult occupation. I love it – with no workshop doors to hide behind, it ensures I’m always on my A-Game. My customers are a mixed bag of trade and public, but I’m generally the person to call when cost is no longer an issue. I vet every customer before I accept a job. Every call or enquiry from a customer is an interview, pass or fail, with no exceptions.

I started a YouTube channel aimed at mechanics and technicians to promote logical, evidence-based testing and showcase the need for ongoing training and professional development after I became frustrated with the public perception of the trade.

We also have a growing community on Facebook that is split into two groups – a free group for subscribers to my YouTube channel, and a subscription based closed group for the more invested technicians.

Vehicle case study

2006 Peugeot 207 – No power steering/multiple warning lights

Every diagnostic job I do follows a set pattern, starting with gathering as much relevant information from the customer regarding how the fault manifests, in what type of weather, driving conditions hot/cold engine, etc. From there, the next logical step is to verify the concern. If it’s intermittent, I ask the customer to re-book when the fault is present or replicable.

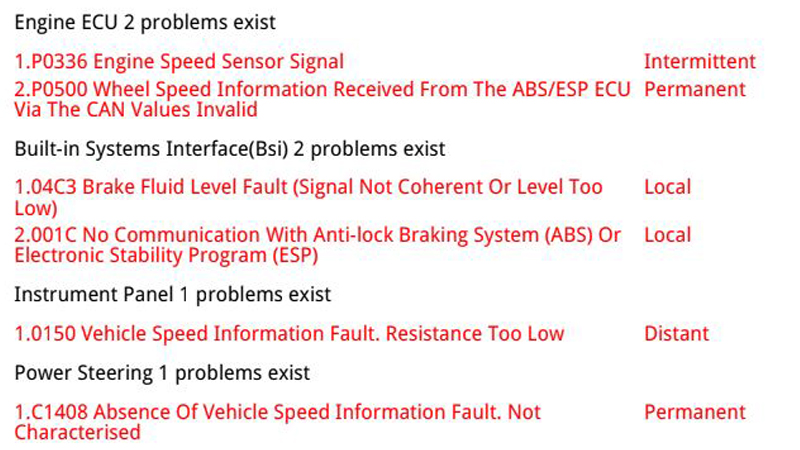

I confirmed that there were multiple warning lights on the dash and that the PAS was inoperative. Whether it’s a simple engine MIL or multiple warning lights, I always do a full vehicle scan to fully comprehend the vehicle’s overall condition.

So, what can we gather from Fig 1? To start, let’s look for common denominators – we can see that Engine, BSI and PAS reported no communication with ABS. Did a simple wiring fault prevent all three modules from talking to the ABS module?

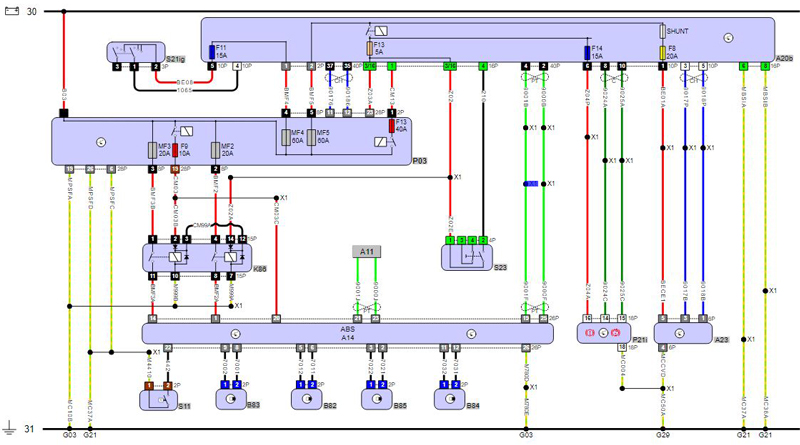

The wiring diagram in Fig 2 (overleaf) shows that the CAN is split into two branches – one that went to the Engine ECU from pins 21 and 23, and another from pins 25 and 19 – with splices that went to the BSI and other modules. We had communication with all modules apart from ABS. All modules get their ABS information from the powertrain CAN, and those not on the powertrain receive that information via the BSI, with the exception of the engine, which gets its information directly via a separate twisted pair on pins 21 and 23.

This effectively ruled out a wiring fault in the physical layer of the network, but it was easily verified by a resistance check of the network. If wiring is intact, you need to see 60Ω between CAN Hi and Lo with the network powered down and asleep.

As I had no communication with ABS, I was almost certainly going to have to check the power supplies and grounds to the unit, so I went straight to the ABS unit, located in the NSF wheel arch.

After removing the dust cover and connector cover, I had easy access for my checks. I tested the power and ground connections with a 4A load, back-probed at the rear of the connector.

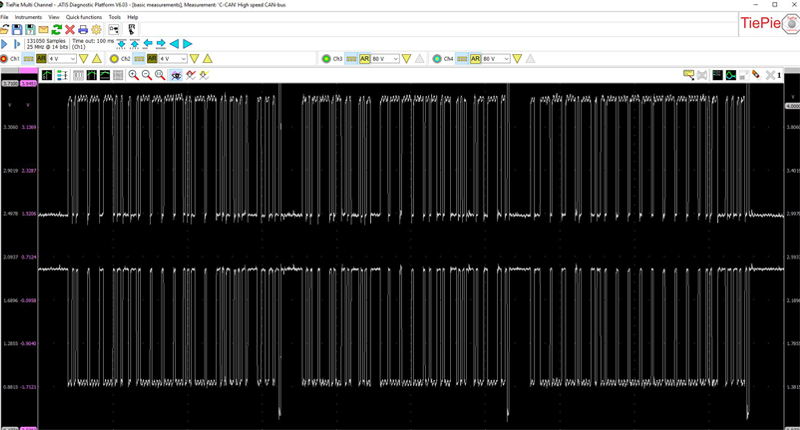

I then checked the CAN physical layer, measuring 60Ω at both twisted pairs on the ABS unit and 120Ω with the ABS unit unplugged. I also checked the CAN signal at both sets of pins on the ABS module, unplugged and powered up – confirming signals from other modules were arriving at the ABS module.

I then plugged the ABS module back in to find that the ABS was not distorting their signals (see Fig 3).

This led to one possible conclusion, the ABS module was not broadcasting on the network.

I needed to be 100% sure that I hadn’t missed anything before condemning a control module; did the evidence stack up? As technical guru James Dillon would ask, what checks would we do if we fitted a module and it didn’t fix it? Why wasn’t the PAS working? Was it a symptom or cause? Was the PAS capable of operating? Was I happy with the inputs to the ABS module? These checks took less than 40 minutes after my arrival at the job, before the ABS module was replaced and the fix was confirmed.