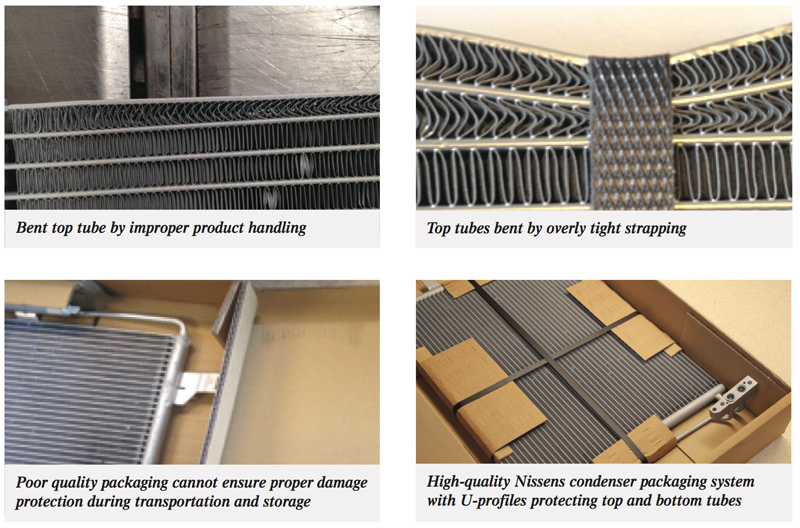

Best practice tips for avoiding mechanical damage to the condenser.

Poor quality packing

Condenser strapping that is too tight inside the box will often crush the top and bottom tubes. As the tube is flat, with a small diameter, the flow in a crushed tube will be extremely limited or completely disabled. Furthermore, most modern condenser tubes are produced in a so-called micro tube design and with inner partitioning walls, making them very sensitive to bending or crushing.

Transport and/or handling damages

The thin aluminum, which the condenser is made of, makes the construction fragile. This requires handling with significant care. Throwing the condenser box, or improper handling during installation, will quickly spoil fragile parts. Even small surface dents or seemingly light bends can impair or limit the condenser inner flow, thus reducing operation capacity. Other areas exposed to mechanical damages are mounting brackets and connection sockets.

Spoiled condenser fins

The thin aluminum fins between the condenser tubes are easily spoiled by bending, hitting, crushing or high-pressure surface cleaning. If the fins are spoiled, the condensation process will become significantly less effective, as the heat exchanging surface of the unit is reduced. Reduced condensation will cause the inner temperature and pressures to rise and the overall system performance to weaken.

BACKGROUND

The condenser is crucial for the AC system operation. It ensures that the refrigerant changes from a gas to a liquid form. This is achieved through the condensation process, where the refrigerant heat is extracted and exchanged with the ambient air.

PROBLEM

Mechanical damage to the condenser is often disregarded as a reason for reduced system performance or for compressor failure. In many cases, failures that are recorded and considered as common reasons for system failure are leakages and surface perforations. However, deformations of the condenser tubes and fins can result in serious system performance limitations. Only one deformed condenser tube is needed to restrict refrigerant flow inside the unit, thus reducing system performance. Furthermore, limited flow will cause abnormally high pressures and temperatures in the loop.

RECOMMENDED SOLUTION

Always handle the condenser with care and do not disregard any damages on its surface. If the tubes and/or fins are visibly spoiled or crushed, replace the condenser with a new unit. Nissens’ condensers are always well packed to ensure maximum protection during storage and transportation. Nissens’ sturdy cardboard boxes protect the condenser – from the factory to the final destination. Inner protective inserts wrap the condenser tight inside the box, while specially designed U- profiles to eliminate any strapping strain impacts.