In the absence of scrappage schemes or other inducements, today’s cars routinely cover much higher mileages than in previous decades before being consigned to the recycler. All the while, individual vehicle components are subject to wear and tear, so inevitably the clutch may start to slip due to age or mileage, or in a car used primarily for short trips, city driving or in hilly terrain. Sachs, a brand of ZF, offers some insight.

Confirm slip

If slip is suspected, first test how effectively the clutch engages and disengages, before dismantling. While each technician will rely on individual intuition and experience, the following are standardised tests recommended by Sachs.

Check for correct disengagement by depressing the clutch pedal fully with the engine idling. After about three seconds, it should be possible to select reverse gear without any gear rattle. If reverse gear is selected immediately and the pedal is depressed, gearshift noise will often be heard, which can confuse diagnosis. With the clutch at normal operating temperature, check for correct engagement. Take the vehicle for a short drive, operating the clutch several times, then stop, apply the handbrake and select top gear.

With the clutch pedal fully depressed, hold the engine speed at 2000rpm, and then drop the clutch. If the engine stalls, the clutch is engaging correctly and is capable of transmitting the necessary power. If it slips, remove the transmission and inspect the clutch assembly.

Rectify Faults

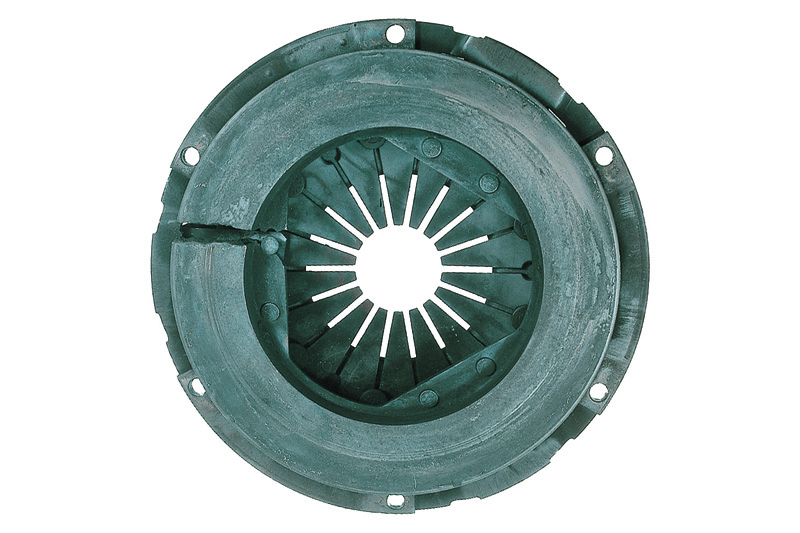

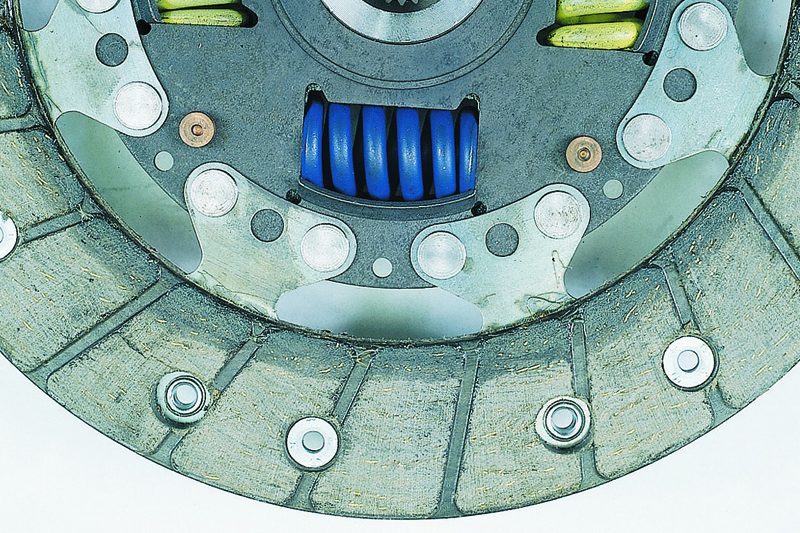

With the clutch cover removed, the causes of clutch slip are usually self-evident. The facings may be worn to the limit (Fig 1) or overheated (Figs 2 and 3), impairing their friction characteristics. Alternatively, they may be contaminated with excess grease from the input shaft splines or by leakage from the crankshaft rear oil seal or gearbox input shaft seal (Fig 4).

Depending on severity, corrosion of the clutch driven plate splines or input shaft may necessitate clutch replacement, or simply cleaning and regreasing. If greasing, use a product that can withstand high temperature and load. Apply to the hub splines and input shaft, slide the driven plate back and forth on the shaft to distribute the grease, and then carefully remove any excess.

Check the entire release system for ease of movement. Drag can delay engagement and cause or simulate slip. If the clutch needs replacing, the release mechanism is likely to be equally worn on its pivoting and sliding contact points. Inspection will indicate whether cleaning and greasing or replacement parts are needed.

Avert future liability

While the transmission is removed, check the surface of the flywheel or dual-mass flywheel (DMF) for heat cracks, damage caused by the worn driven plate, or evidence of overheating. Where a DMF is fitted, assess both rotational and tilt play. Where a concentric slave cylinder (CSC) is fitted in place of a conventional release bearing, fork, guide tube and slave cylinder, it should ideally be replaced at the same time as the clutch assembly. If the original DMF or CSC fails to complete a second lifecycle, the gearbox will need removing again, landing the customer with a further repair bill – and possibly doubts about how thoroughly the job was done first time around.