Shaftec explains how and why the company’s remanufactured EPS racks are supplied with all fault codes cleared.

Before you can successfully fit a replacement non-VM specific aftermarket Electric Power Steering (EPS) rack, the original fault codes which rendered this part obsolete in the first place will have to be cleared from the vehicle’s memory. If this isn’t done, the car will automatically transfer the old fault code to the new unit. Nothing will be able to clear this – except the fitment of a further brand new unit.

Not clearing the faults can have other unpleasant knock-on effects: the steering Electronic Control Units (ECUs) in some cases control other parts of the car. So this whole affair could, in a worst case scenario, immobilise the vehicle.

To clear the fault codes, you need the correct diagnostic equipment, which is expensive and thus requires substantial investment. Alternatively, you can source a remanufactured steering rack which has already been ‘virginalised’. This means that the investment falls to the parts manufacturer.

This is where Shaftec comes in. The memory on all remanufactured EPS racks supplied by the company is completely wiped. This means that the part can be plugged in and, in the vast majority of cases, will automatically learn all the relevant details from the car it is fitted to. Furthermore, Shaftec now covers the electrical terminals with a security sticker to reassure the mechanic that the unit hasn’t been fitted to anything since it has been virginalised.

How does Shaftec do this?

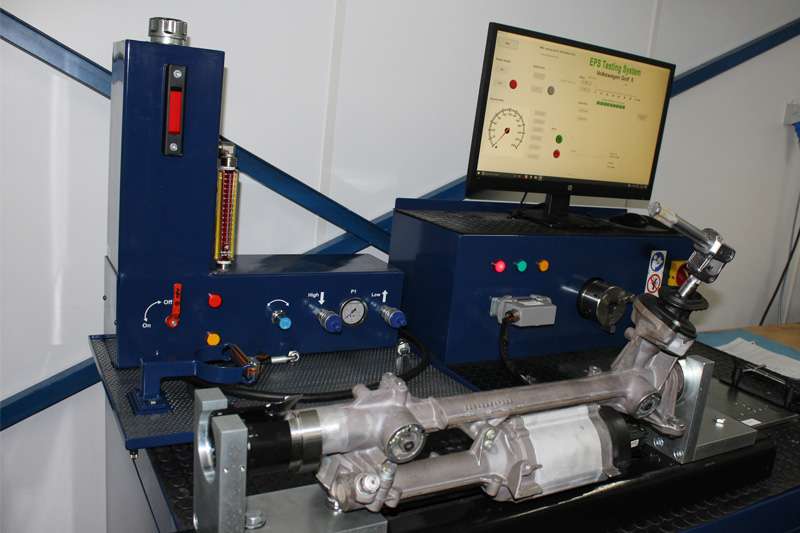

The latest addition to the Shaftec family – its mobile EPS diagnostic machine – reads and clears fault codes on all electric steering components. This is done both at the start of the process, to make sure the core unit is suitable for remanufacture, and at the end of the remanufacturing process, to confirm all is as it should be before the part is boxed and labelled.

It plugs into the terminals of the steering unit, providing the electricity to power up the component and retrieves any fault codes logged in the memory before the mechanical elements are tested on the EPS testing rig. This original chassis code is then cleared and the unit is virginalised. The benefits of this ‘plug and play’ ethos include a bigger range of part numbers available, speedier diagnosis of faults and massively increased in-house control.

This state of the art diagnostic equipment tests assistance, speed and angle sensors during a ‘real world’ simulation with visual readouts on the screen. Each unit has a locating position on the rig: pumps on the left, racks on the front, and column drives on the right. They are securely located in these positions to allow the simulation to occur, and to test that the parts work as they should in a driving vehicle. Torque sensors and steering angles can be checked, fault codes stored in the ECU can be cleared and it can also assess the assistance the rack is giving at different speeds (as they are speed variable), providing a much clearer picture of the component’s ability to react to real life situations.