Based on a review of recent warranty claims, Wayne McCluskey, Technical Training Manager at ZF Aftermarket UK, offers advice on adhering to best practice when installing a Sachs clutch or concentric slave cylinder.

As with any product, a certain level of warranty returns can be expected despite stringent checks at every stage of manufacture and during quality assurance procedures. However, problems are usually related more to the fitting technique than to actual product quality.

Installation tips

Despite clutch replacement being a routine operation for aftermarket workshops, ZF Aftermarket still receives Sachs clutches returned under warranty showing telltale signs of incorrect installation. In most cases, simple precautions during component replacement will avoid such problems, saving time, cost and risk to reputation from unsatisfied customers.

Clean and inspect

Before installing a new clutch, clean the inside of the bellhousing and the clutch actuation system, including the release fork, release bearing guide sleeve, and transmission input shaft splines. Once spotless, identify any signs of wear that could prevent the new clutch from releasing or engaging correctly, and replace any affected components before proceeding further.

Measure lateral runout

Multiple opportunities for careless handling in the supply chain mean damage can occur during transit to the workshop. It’s therefore advisable to measure lateral runout of the clutch driven plate prior to installation. To prevent drag and ensure smooth gearshifts, runout should be less than 0.5mm, so correct any distortion before fitting.

Centre the driven plate

Precisely centre the driven plate on the flywheel to ease the installation of the transmission and minimise the risk of damaging the hub spline in the process.

Lubricate sparingly and keep friction facings clean

Special grease is included with every new Sachs clutch to prevent fretting corrosion. Apply this carefully to the driven plate hub splines – a toothbrush is an ideal tool for this – then slide the hub back and forth a few times on the input shaft splines and remove any excess lubricant. Ensure that the pressure plate and friction material are not contaminated by grease.

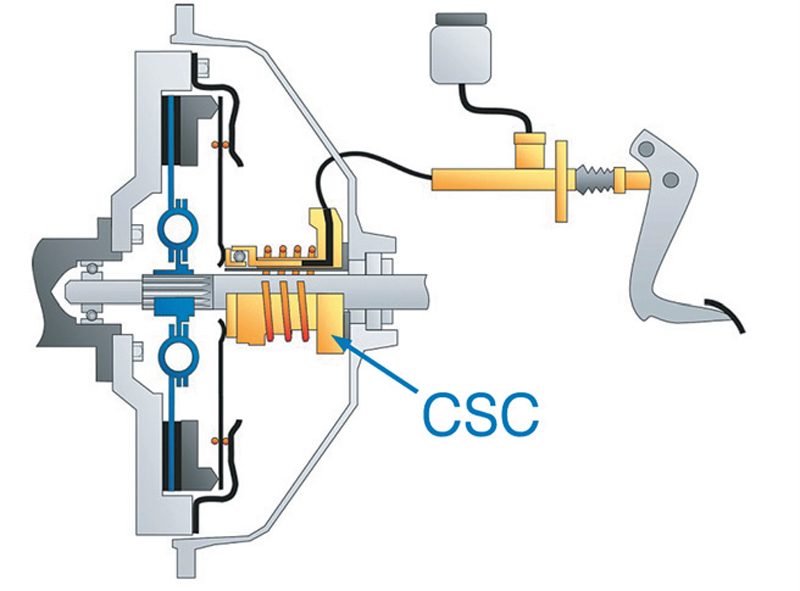

Concentric slave cylinder (CSC) fitting tips

Most CSC failures occur during or immediately after fitting or bleeding. If the clutch exhibits stiffness, juddering or fluid leaks following CSC replacement, this suggests a damaged CSC.

Basic precautions

Check that the size and position of the new CSC’s hydraulic pipe connection matches that of the unit being replaced. Always use the correct mounting screws and ensure that the CSC is flush with the surface of the bellhousing before tightening them. Over-long screws may prevent the guide sleeve being firmly clamped to the bellhousing, causing it to separate from the housing and the seal when pressurised. If additional sealant is needed, apply evenly to avoid the cylinder becoming skewed.

Handling

Do not compress the CSC before fitting; this can damage the rubber seals before they are fully lubricated. Many CSCs rely on their backplate being secured in place by the gearbox, and prior compression can dislodge this plate, causing a leak. Never pressurise the CSC until it is fully installed in the gearbox.

Flush and bleed

Flush old hydraulic fluid from the system and refill with fresh fluid before fitting the new CSC and bleeding. Ensure the fluid is the correct specification, otherwise the CSC seals may swell or disintegrate.

Overstroking

Low pressure bleeding is preferred over other methods; bleeding by rapidly pumping the clutch pedal can cause the CSC to overstroke. This will damage the internal seals when they contact the retaining ring on the end of the guide tube, causing fluid to leak into the gearbox bellhousing. Where a pressure regulating valve is incorporated in the hydraulic circuit, failure of this valve can also cause the CSC to overstroke.

Driven plate orientation

If the driven plate is installed facing the wrong way, the hub boss could bear on the CSC guide tube, generating enough frictional heat to destroy the unit. Observe markings such as ‘Getriebeseite’ (gearbox side) on the driven plate, which indicate the correct orientation.