Arnott Europe, the air suspension specialist, provides PMM readers with a refresher on best practice for working on air suspension systems as business starts to pick up pace once again.

Safety and preparation

When working on the air suspension system, ensure that you wear protective glasses, hand gloves, and ear protection. Ensure that the pressure has been released and that the power supply to the compressor is disconnected before disassembling the air hoses and components.

Visual checks

Several issues can be diagnosed visually. If, for example, a vehicle drops more than 2.5cm overnight, this indicates a leak in the system. If the car is lower in one corner, or the car is not levelled, this can also be caused by a defective valve block. A burnt-out compressor can be confirmed by smell and the colour of the metal body. Brown-coloured labels on the compressor unit are also good indicators.

Depressurising

Depressurising the system can be done either at the compressor or the air bellow side. Never fully remove the air fitting all at once, instead remove it gradually to relieve the pressure. Depending on the vehicle’s make and model, a diagnostic tool may be needed to activate the solenoids to depressurise the air bellows. You can recognise this by the presence of a connector on the air spring.

Jack mode

Check if the vehicle features a ‘jack mode’. If present, use it to prevent the air being released from the bellow when jacking up the car. If not present, the car can be jacked without any precautionary measures. Some systems automatically recognise that the car is jacked and retain the desired amount of pressure in the air springs.

Inflation

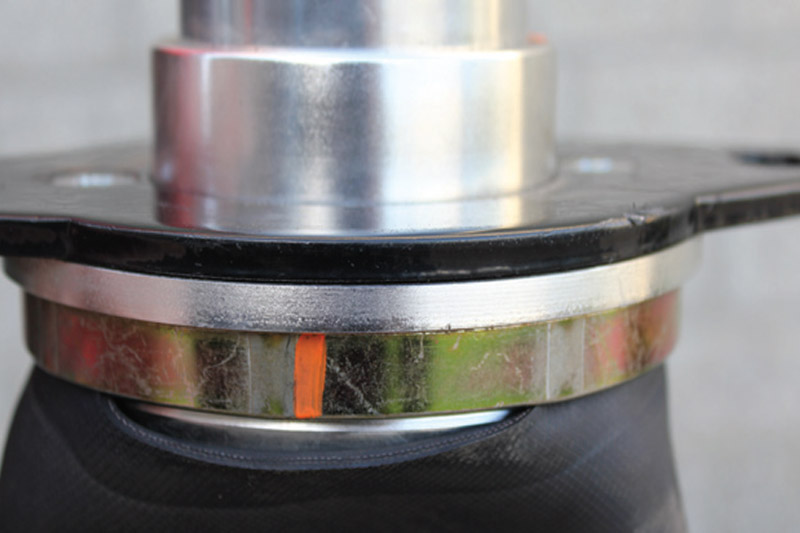

Never fully lower the car with the lifting device when the air suspension system is depressurised, as the air spring could unfold incorrectly, and the crimp ring may dislodge. The relay could get damaged, or the compressor could burn out in its attempt to pressurise the system to the operational level.

The air springs should be mounted the way they came out of the box. Do not stretch them or pre-pressurise them, as during inflation they could fold out incorrectly and get damaged.

Tightening the VOSS connector

VOSS connectors usually do not need tightening, and doing so may damage the thread and cause air leakage. Always respect the manufacturer’s torque specifications, as over-torqueing can result in damaged or broken threads.

Don’t just replace – find the root cause

Always replace the relay when mounting a new compressor. Often, the relay has become ‘sticky’, causing the new compressor to continuously operate. This will eventually lead to a burnt-out compressor. Remember that the compressor is usually not the actual cause of a non-functioning air suspension system, but rather the consequence of a large leakage in another part of the system. Therefore, making the correct diagnosis is crucial. Check all lines, connections, and air springs for leaks after the compressor is working again.

Struts and shocks

Critically inspect the air suspension strut or shock absorber for oil leakage when replacing a leaking air spring. Oil deteriorates the rubber of the air bellows and drastically lowers the lifespan of the part. If the shock absorber is no longer performing its task properly, the air spring overworks and will get damaged quickly.

Diagnostic tools

After the test drive, ensure that no fault codes are re-entered into the system. Check the height sensor parameters with a diagnostic tool and adjust if necessary; this ensures the correct height at each corner of the vehicle, enabling the system to respond correctly to inputs when driving. Additionally, perform a wheel alignment when the shock absorber or strut is replaced.

Always perform a dealer software update if this is required in the installation manual. Ignoring this will cause the compressor to not work as it should, potentially leading to a burnt compressor.