Quality turbocharger repairs are infinitely possible, as long as the correct equipment is being used. Ian Warhust, Owner of Melett, tells us more.

For many years now an ongoing debate over whether a turbocharger can actually be repaired has taken place. The origins of the ‘repair’ debate can almost certainly be traced back to 2004. At this time some OEM turbo manufacturers decided to pull out of the repair market, citing the fact that most repairers didn’t have the correct specialist balancing equipment for the new higher speed turbos as a reason for doing so.

Over the last decade, vehicle technology has continued to improve to reduce emission levels in order to meet the Euro 4, 5 and 6 regulations. As a result of these changes, engine and turbo technology has increased in complexity, and the settings and control of advancements, such as the variable nozzles, have become more critical to the correct operation of the turbo. This is now presenting new challenges to turbo repairers as the correct setting of the turbo on later models now requires further specialist equipment in the form of an air flow rig.

What is a Variable Nozzle Turbo?

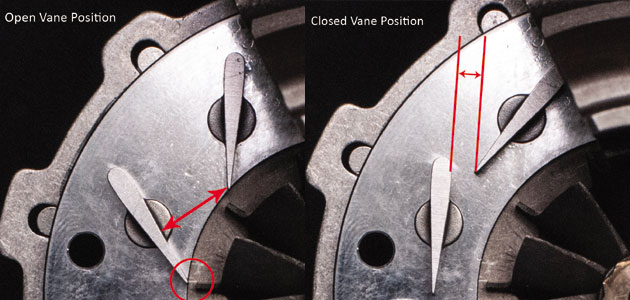

When a turbocharger is matched to an engine, the engineers have to balance the low speed response with high speed efficiency. The variable nozzle (also referred to as a variable geometry), is designed to change the exhaust gas inlet area with the engine speed to closely match the desired boost requirements of the engine.

For low speed response, the nozzle vanes move to the ‘closed vane’ position to reduce the nozzle area – increasing gas speed through the turbo and giving improved response at low engine speeds – similar to squeezing the end of a hose pipe to make the jet of water more powerful. As the engine speed increases, the actuator moves the nozzle vanes to the fully open position to maximize the exhaust gas flow.

Vane setting accuracy

When the first variable nozzle turbos were launched, it was a step change in turbocharging technology. Air mass sensors and ECUs were programmed to manage the whole engine system – however relative to the current engines – and tolerances for acceptable air flow were set quite high. When setting up a new turbo, vane setting positions are determined using accurate air flow equipment, which ensures that the ‘minimum vane opening’ position is set to allow a specific mass of air flow through the vanes. If the vanes are too closed, this can cause choking of the engine and overspeeding of the turbine. If it is set too large, the turbo will have too much ‘lag’ and not respond as well as it should.

Traditionally, turbo repair workshops did not use an air flow rig to correctly set the flow. The actuator position was based upon an accurate measured position of the actuator arm and this produced acceptable results that allowed the repairers to keep on repairing.

In reality, this method of setting the vanes can produce inaccuracies in the flow of air. The actuator arm measurement is set against a cast finish on the bearing housing, the position of which is not accurately controlled during manufacture. However, as the engine would accept quite a large tolerance of air flow, the repaired turbo still performed well compared to the broken turbo which it replaced, so the vehicle owner was still happy with the results.

On older turbo repairs, the variable nozzle position had to be a long way out before the performance was excessively affected or for the ECU to flag a problem. From an OEM perspective, this is not acceptable and is the reason for their lack of support for repairing.

The need for accurate air flow setting of turbos was well understood by reputable repairers, and hence some quality repairers developed their own air flow equipment to accurately set their turbos, resulting in a reduction in warranties and the ability to build on their reputation as a quality repairer.

Today’s turbos In recent years, as engines have improved to meet tighter Euro emission regulations, the control over the whole air/fuel system has improved dramatically. Many premium brand vehicles have moved to electronic actuation which gives positional feedback to the ECU. Some more advanced turbo controllers now sit within the CAN Bus, talking directly to the injection system and air mass sensors to respond more quickly to engine demands. For these turbos, the settings are either correct and accepted by the ECU – or not – which can result in warning lights, limp home mode or refusal to start.

In recent years, as engines have improved to meet tighter Euro emission regulations, the control over the whole air/fuel system has improved dramatically. Many premium brand vehicles have moved to electronic actuation which gives positional feedback to the ECU. Some more advanced turbo controllers now sit within the CAN Bus, talking directly to the injection system and air mass sensors to respond more quickly to engine demands. For these turbos, the settings are either correct and accepted by the ECU – or not – which can result in warning lights, limp home mode or refusal to start.

As more of the Euro 5 compliant vehicles enter the aftermarket, problems will arise and, for some turbo models, we’ve already reached the point where flowing the turbo is a necessity that is only made possible by workshops that have the correct equipment. However, this will naturally mean that older turbos also become more widely repaired using air flow equipment, which will bring further improvements to the market.

Making the right choice

Traditionally, in the turbocharger aftermarket the customer had a choice between a new OE turbo and a remanufactured turbo. Over the past 10 years the turbo repair market has changed significantly with a number of new repairers entering the market and the number of suppliers of parts. What we now have is three tiers:

1. A new OE turbo.

2. A high quality remanufactured turbo, repaired using quality parts and the correct equipment.

3. A poor quality repaired turbo, using inferior quality, low cost parts.

There will always be a market for all three options, depending upon the vehicle owner’s requirements, but it is important that garages understand that there are different levels of quality for repaired turbos and therefore a different level of associated cost.

When outsourcing your turbo repairs it is crucial to consider the real cost of replacing a turbo and to educate your customer about the different options and associated risks for choosing cost over quality, so they can make informed decisions.

Many turbo specialists in the UK already have a flow rig and are repairing turbos to an excellent standard.

Warranties are reduced when turbos are repairing using quality parts.