Gates describes a solution to a timing belt replacement issue that will reduce the number of comebacks for garages.

Models: Skoda, VW, Audi, Seat

Petrol engines: 1.6L, 2.0L

Year: Wide ranging

The scheduled replacement of timing belts in Synchronous Belt Drive Systems (SBDS) fitted to 1.6L and 2.0L petrol engines in the Audi, Seat, Skoda and Volkswagen ranges, is an uncomplicated procedure, however, some installation issues have been reported. For a typical installation, technicians require the Gates PowerGrip K015489XS kit (belt plus tensioner), or either the Gates PowerGrip KP15489XS-1 kit, or KP15489XS-2 kit. Both of these kits contain a belt, a tensioner and the appropriate OE-quality water pump for the particular application.

The problem

Once the installation has been completed and the engine allowed to run for a short time, some technicians have reported problems with noise from the drive system. Some identified a clicking sound and recorded that it was most noticeable in the warm-up phase, as the engine approached operating temperature. If this kind of problem is allowed to persist and the engine continues to run, belts have been observed to shift from the central position on the tensioner pulley and then ‘track’ towards the flange.

Unless corrected, this will inevitably lead to premature drive belt failure.

Diagnosis

Examinations by Gates engineers have established that the clicking sound is being caused by the impact of the lever stop on the base plate stop. This is clearly caused by an installation error. Where drive belts have failed prematurely, inspection of the pulleys shows black residue marks left behind by the belt (Fig 1).

These black residue marks are evidence of excessive friction. When considered together, all of these facts point towards tensioners that have been set up incorrectly. A thorough analysis of similar incidents revealed that in each case, the problems were the result of common installation errors that were avoidable.

Solution

When replacing timing belts on any SBDS fitted to Skoda, VW, Audi and Seat models in the range equipped with 1.6L and 2.0L engines, two simple rules must always apply:

1. Use the lug to position the tensioner in the precise position

2. Take no shortcuts with the tension setting cycle

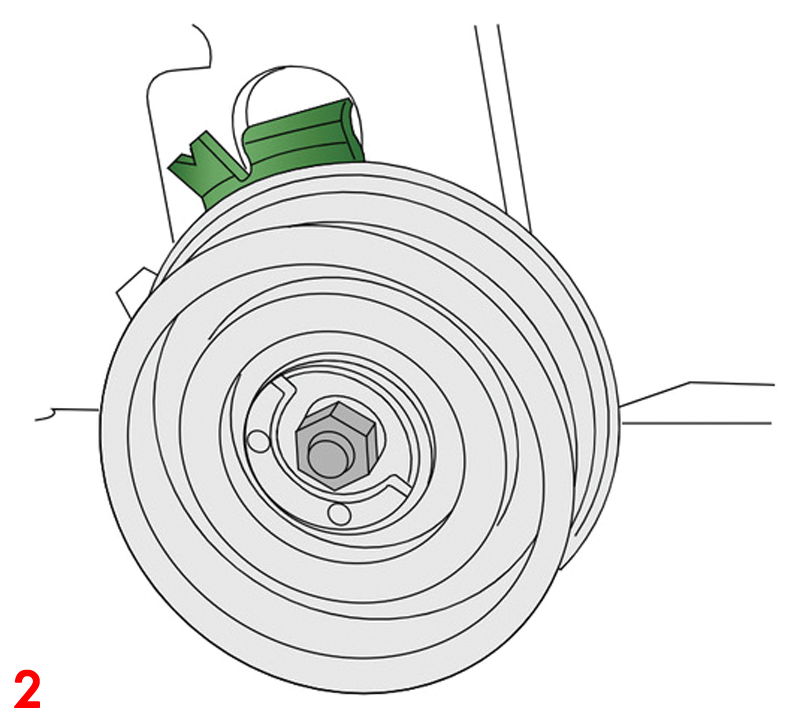

Note the lug on the tensioner highlighted in green (Fig 2). This is designed to fit into the centre of the appropriate slot on the engine block. It ensures that the tensioner is aligned correctly and that the SBDS can operate efficiently once the belt is installed.

Belt tension is critical to the high performance of the engine. In order to achieve the correct tension on any SBDS fitted to these particular engines, technicians must use an appropriate adjuster to set the tensioner according to the manufacturer’s fitting instructions.

With the lug located in the slot and the tensioner confirmed as correctly positioned, before your final tension adjustment, use the adjuster to turn the tensioner counter clockwise, until it stops (maximum tension). Use the adjuster to turn the tensioner back to the original position (minimum tension).

Repeat the cycle five times. That number five is important. Repeating the procedure five times enables the mechanism to adopt the optimum setup position and ensures that the belt tension has been set correctly.

Conclusion

While the SBDS is designed to be robust, it is a highly sensitive mechanism and its efficiency is all too often compromised by the use of incorrect tools, or a failure to follow a vital step-by-step installation procedure. These procedures are also designed to be robust, but they can only continue to deliver consistent results when followed precisely and to the letter.

Gates reports that in garages where the aforementioned two simple rules are now being applied, problems have not recurred. Moreover, the tensioners are now able to maintain belt tension for the lifetime of the belt, and are able to continue doing so without any unnecessary noise.