PMM speaks to febi about its clutch manufacturing pedigree.

What are the latest advancements in clutch technology that Blue Print has introduced, and how does the Clutch Competence Centre in Durmersheim contribute to this?

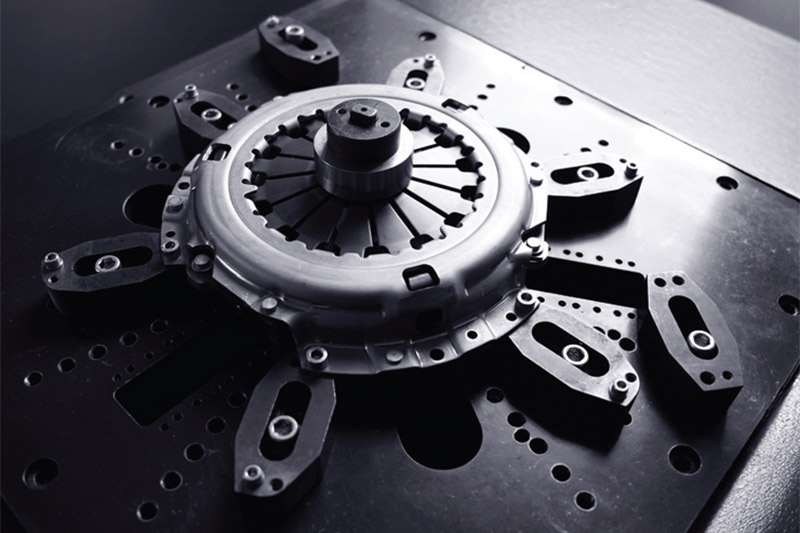

The Bilstein Group Clutch Competence Centre is a cutting-edge testing centre which goes above-and-beyond the usual standard required in benchmarking clutch components against OE, ensuring every component meets original equipment standards for reliability and performance.

Can you elaborate on the 35 performance checks conducted during testing, and how they ensure OE-matching quality and longterm reliability?

Each clutch component is subjected to dimensional checks based on defined parameters using a 100% precision Faro Gage both in product development and when in stock. We test the pressure plates according to Blue Print specific parameters and tightness tolerances. These performance checks on in-house test benches guarantee the correct clamping force + a safety margin, comfortable pedal forces & balanced weight distribution in the clutch covers.

Our clutch disc facings & torsion springs come directly from premium suppliers where production is subject to strict quality control to ensure long service life. All clutch discs are produced exclusively according to Blue Print-specific requirements.

We perform durability checks ensuring excellent cushion deflection for a smooth and gentle start, optimum clutch configuration for performance and durability, for each application & measuring programs developed internally for testing and tolerance monitoring to ensure consistent quality.

The clutch discs then go through performance tests, which check for Sufficient lift-off for clean disengagement of the clutch, for smooth gear changes using a measuring program developed in-house to verify the permissible tolerances, for consistent quality.

Our quality standards are certified against ISO 9001:2015 and were last audited in February 2025. Blue Print combines expert engineering, high – grade materials and rigorous quality inspections to ensure every product meets ISO manufacturing standards. Each clutch kit is a direct replacement for the original part, giving workshops confidence in every installation.

With coverage for over 50,000 vehicle applications, how does Blue Print determine which models to develop clutch kits for?

With a range covering 80% of market demand, Blue Print aims to offer an ‘All Makes’ range for European and Asian vehicles with a ‘Fast to Market’ approach.

We do this through constant research conducted utilising Official Manufacturer Electronic Parts Catalogues where every product is linked directly to an OE reference for accuracy and efficiency. New references are checked against supersession information for platform-shared links and existing range data characteristics. If no links are found, they are then assessed on vehicle popularity and usage to determine a priority list and OE samples are obtained. We never use competitor cross-referencing to identify parts – only OEM information.

How do SMARTFIT Conversion Kits compare to traditional OE clutch kits in terms of performance, longevity and ease of installation?

SMARTFIT kits from Blue Print are a high-quality aftermarket alternative to Self- Adjusting Clutches. The advantages of these SMARTFIT kits include quick and easy fitment, because conventional clutch covers are used, and no special tools are required to install them. There is no need to secure the clutch cover without applying a counterforce. This not only significantly reduces the time required, but also the risk of incorrect installation.

Beyond product quality, what technical support, training and resources does Blue Print provide to factors?

We have various things available to help technicians beginning with supplying the full detailed fitment instructions in every clutch kit, we have a YouTube channel with technical videos including fitment videos, we also offer in depth clutch replacement technical articles and specialist PROTIPS.