September 2014 is going to represent a massive change in diesel vehicle production with the introduction ofthe Euro 6 standards. The Euro 6 standard requires manufacturers to achieve a reduction in NOx from 0.180 to 0.080 g/km. This is a whopping 50% reduction over the current Euro 5 standard with the only reliable way of achieving this – it would appear – through the use of an SCR system.

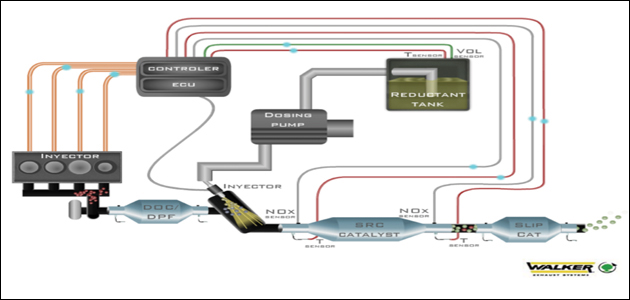

SCR system make-up

This system will comprise of an injector downstream of the particulate filter which will inject a fine atomised spray of ‘Adblue’ solution continuously into the exhaust gas whilst the engine is running.

SCR system diagram

The concentration of this solution will have to be 5% of the diesel consumed, meaning that for every 100 litres of diesel used, five litres of Adblue will potentially have also been consumed. By that reckoning a 25 litre Adblue tank will need refilling every 5,000 miles on average. Whilst the industry acknowledges that this system works and is needed, I’m not at all convinced that the public who will own one of these vehicles will be quite so amenable.

The other components of the SCR system will include a mixer after the injector to ensure thorough homogenisation of the solution and the exhaust gas. This is actually a very technical component that required a lot of development work for it to function successfully on small-sized diesel engines.

We then have the first of a selection of temperature and NOx sensors and SCR (selective catalytic reduction), which will effectively convert the NOx into harmless nitrogen, oxygen and water. A further temperature and NOx sensor will ensure that this process is working within design specifications.

Any deviations from this will not only put the vehicle into ‘limp home’ mode, but will almost certainly inhibit the car from restarting once it has been turned off, if the malfunction has not been corrected.

Adblue concerns

The Adblue solution itself will freeze at -11̊˚C, therefore the storage tank on the vehicle for the Adblue will almost certainly have to be heated to ensure the ambient temperature doesn’t drop below this value.

The Adblue storage tank

Equally if Adblue is subject to temperatures above 50̊ ˚C (e.g. in paint ovens) it will almost certainly cause the Adblue active agent (urea) to break down, causing the system to malfunction. This, at best, would result in extremely limited functionality, but more likely would not allow the vehicle to restart.

There are concerns within the industry over the future quality of the Adblue solution, while exposure to bright sunlight and a limited shelf life of just a year or so are other issues the IAM will have to deal with. It is well known within the commercial sector that some unscrupulous distributors are diluting their stock of Adblue. If a diluted solution was used, this would now be detected by a Euro 6 SCR system, causing it to operate in limp home mode and then the engine would not restart once it has been turned off.

There is also some apprehension about the calcifying/corrosive nature of the chemical (ph9) in terms of its effect on the longevity of system components. Therefore, the exhaust system of a Euro 6 diesel vehicle with all its DPF components, and now its SCR reduction components, could have up to 12 sensors on just the exhaust system alone.

As you can see a clear and precise understanding of how this system functions will be imperative for any technician to work on these vehicles from a maintenance and repair perspective.

Current production

Both VAG and Mercedes have already been supplying cars and vans with this technology for more than a year, and a recent change in the filling process is now catching a lot of garages out.

You must be aware of the service issues associated with this technology as in less than two years virtually all new diesel vehicles will have this technology to comply with the Euro 6 legislation.