ALLDATA Europe has announced the launch of ALLDATA Maintenance Schedules, a one-stop-shop solution for workshops.

As cars become smarter, with advanced electronics, sensors and alternative powertrains, the definition of ‘routine maintenance’ has become nuanced. What used to be a simple service now involves navigating manufacturer-specific processes, safety protocols for high-voltage systems and detailed torque sequences, all while juggling customer expectations for speed, transparency and value for money.

It is easy to see this as a daunting prospect, but ALLDATA Europe believes this is actually an opportunity, if workshops invest and follow OEM repair guidance and best practices. Workshops can achieve fast, reliable repairs and strengthen customer trust and satisfaction.

ALLDATA Europe has persisted with its philosophy of “remove the guesswork, make complicated repairs simple”; experience and gut instinct are valuable attributes, but as vehicle repairs become increasingly complex, modern technicians need OEM repair information at their fingertips.

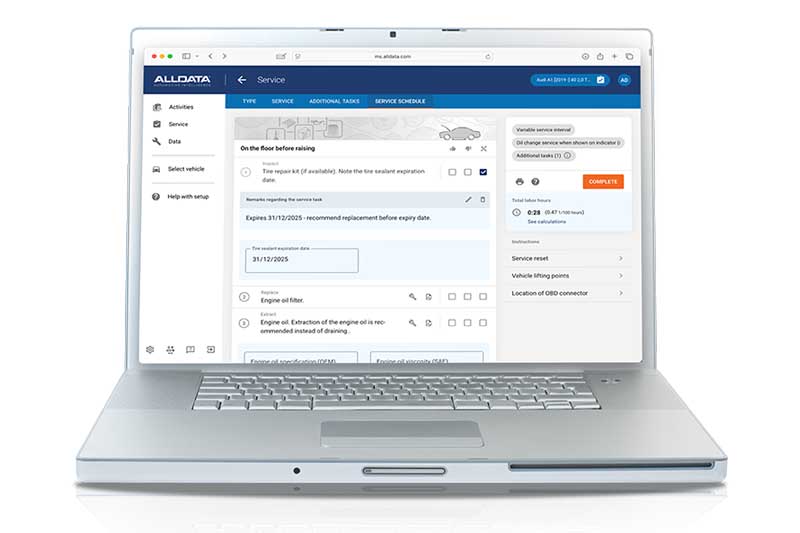

This is why ALLDATA Europe has added ALLDATA Maintenance Schedules to its product portfolio. Integrated into the established ALLDATA Repair platform, turning static service plans and checklists into digital guides, Maintenance Schedules provides direct access to original service plans and data of 61 vehicle manufacturers.

Maintenance Schedules determines exactly what tasks need to be undertaken at a specific mileage or time interval, according to the original manufacturer’s schedule; therefore, rather than guessing what a 60,000 mile service should include, Maintenance Schedules will generate a complete, manufacturer-specific maintenance plan, like core and additional service tasks, replacement intervals for wear parts and special notes for different systems.

Alongside repair instructions and labour times, Maintenance Schedules transforms ALLDATA Repair into an all-encompassing, one-stop-shop workshop companion.

Digitalisation is said to be reshaping daily workshop operations. Tim Benson, Owner of Oldfields Garage and ALLDATA Repair subscriber, explained: “ALLDATA Repair has allowed us to redefine how we approach diagnostics. It is built into the first stage of our process. Spending time up front checking procedures saves far more time in the long run.

“While complicated fixes stand out, such as a previously unsolvable fuel filter replacement made simple with an OEM procedure, the biggest change is in daily usage. Removing trims, door panels or accessing buried components is faster and safer, thanks to accurate step-by-step guides.”

This is said to demonstrate the importance of integrating technology into workshop processes. ALLDATA hopes its Maintenance Schedules will be able to assist workshops with that.

By consolidating multiple brand portals into one platform, workshops can reduce subscription costs, cut training times and ease administrative headaches, freeing technicians to focus on servicing vehicles.

The independent aftermarket has always thrived on adaptability. What’s changing now is the speed of change. Electrification, ADAS and connected diagnostics are just some of the reasons why vehicle repair is becoming more complex.

Furthermore, customers expect transparency as much as technical skill. With manufacturer-aligned data, processes and documentation, workshops can substantiate the work carried out, reinforcing confidence and credibility.