Although it may appear to be a relatively simple task, tightening wheel bolts often in fact causes headaches and unwanted problems. Febi explores the science behind tightening and offers its best practice advice to workshop technicians.

Wheel bolts are still the traditional joining elements for wheels, brake discs and wheel hubs. Although a lot has already been written on this topic, and attachment of the wheel by means of bolts is self-explanatory, problems continue to occur regularly in practice. The risks associated with a wheel that is tightened too much or too little are frequently underestimated. It is imperative to bear some aspects in mind to avoid them as far as possible.

What is the pretensioning force?

The bolted joint of the wheel should absorb all dynamic loads (especially vibrations) during normal driving with the result that the bolted assembly (wheel-brake disc-hub) behaves like a single component. For this to occur it is necessary to generate a pretensioning force that is defined as the required force in the axial direction when tightening a bolt. The torque with which the pretensioning force of the bolt is applied during fitting generates a tensile force in the thread which leads to elastic elongation of the bolt and contraction of the wheel rim.

In this case, imagine the bolt as a tension spring and the joined components (wheel hub, brake disc and wheel rim) as a compression spring. The elastic expansions or compressions of the individual components lead to the frictional grip occurring between the elements being maintained under all the loads arising.

Parameters such as tightening torque, friction in the thread, material condition and dimensions of the bolt as well as its strength rating having an effect on the pretensioning force.

Example:

The pretensioning force for a wheel bolt M12x1.5 of strength rating 10.9 tightened with 120 Nm corresponds to approximately 57,000 N – that’s around 5.8 metric tons! It is only possible to speak of professional fitting if all the parameters have been taken into account.

If the pretensioning force is too low

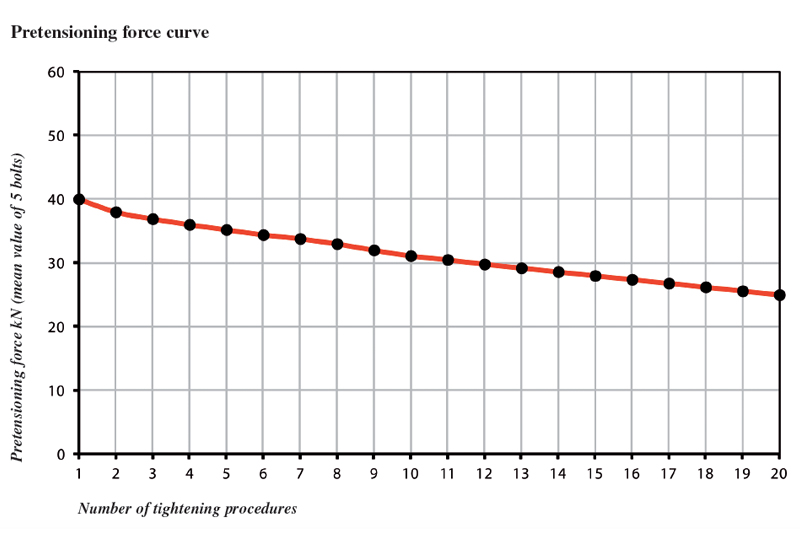

If the wheel bolt is tightened with a torque that is lower than that specified by the vehicle manufacturer, the required pretensioning force will not be achieved. This leads to vibration of the components under load. The consequence may be loosening of the bolt and, in the worst case, loss of the wheel. The pretensioning force changes when a wheel bolt is tightened several times. The surface of the thread is stressed each time it is tightened or loosened, which increases the friction in the thread and under the bolt head. The torque wrench releases sooner than specified due to the increased friction value. As a result, it is no longer possible to achieve the vehicle manufacturer’s envisaged pretensioning force at the junction between wheel, hub and bolt (see graph).

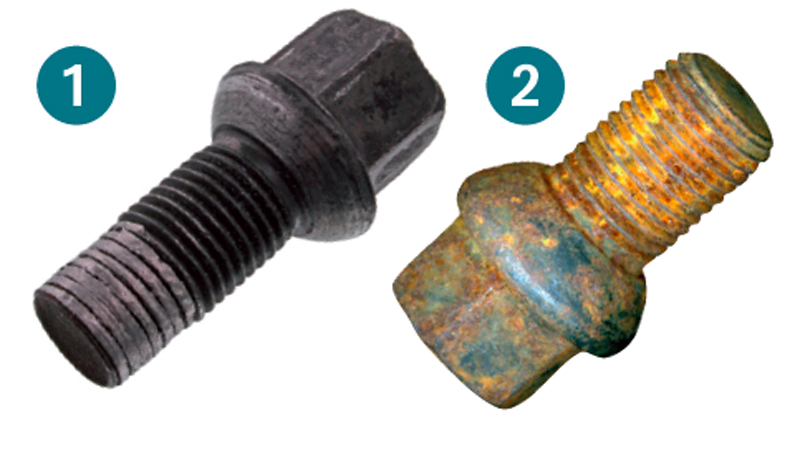

The friction value increases enormously in the case of rusted, dirty or damaged wheel fastenings and the result here, of course, is a sharp drop in the pretensioning force (Figs.1&2).

If the pretensioning force is too high

It may be assumed in the case of wheel fastenings that are tightened without using a torque wrench that the bolt will be overtightened. This leads to elongation of the wheel bolt or to compression, particularly of alloy wheels. As a result, it is no longer possible to build up the required spring action. This is referred to as “plastic deformation” (Fig.3).

In the case of wheel fastenings that are lubricated subsequently, the friction decreases enormously with the result that the wheel fastening is pretensioned too much even when using a torque wrench. In the worst case, the bolt shears off.

Fitting tips

- You must adhere to the vehicle manufacturer’s recommended tightening torques.

- Use only torque wrenches which ensure that the specified torques are complied with exactly.

- The bolts must be replaced if there is any rust, plastic deformation or damage to the threads.

- Check the threads of the wheel hub for dirt and corrosion, replace if damaged Clean corroded wheel contact surface.

- Check that the contact surface of bolt and rim are free from dirt, oil and grease and any damage Tighten wheel bolts evenly and in the correct order. It is imperative to comply with the manufacturer’s specifications. Never use impact wrenches when tightening. Do not use any oil or grease.