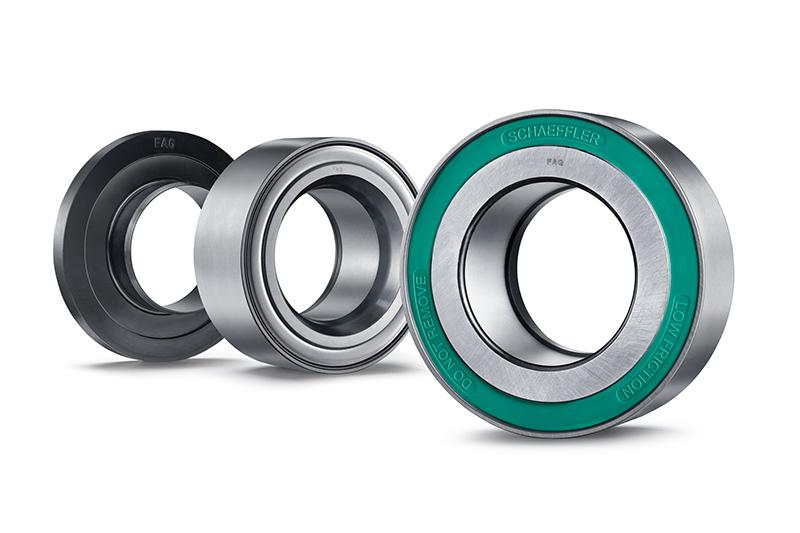

Schaeffler Vehicle Lifetime Solutions (VLS) has introduced an updated version of its FAG Repair Insert Unit (RIU) for commercial vehicles.

The pre-assembled unit has been designed to make OE quality wheel bearing replacements simpler in truck, trailer and bus hubs. The RIU can also extend maintenance intervals and has a patented sealing cap, helping to lower diesel consumption and CO2 emissions by reducing friction levels. The result: less time off the road means lower operating costs.

The FAG Repair Insert Unit is pre-assembled and sealed. Inside, two tapered roller bearings are connected by means of a snap ring, and are lubricated for life with the appropriate grease at the factory. This is said to eliminate the risk of using the wrong specification or contaminated lubricant in the CV workshop.

The updated version of the FAG Repair Insert Unit is the first to feature a patented sealing cap made of polyamide plastic, which replaces the previous conventional two-lip seal. The sealing cap is mounted contactless on the outbound bearing, reducing friction, resulting in an energy saving of up to 38 watts per wheel hub. This equates to lower fuel consumption for fleet operators, resulting in cheaper running costs and improved emissions levels.

Samuel Braun, CV Vice President at Schaeffler VLS, said: “Wheel bearings are subject to natural wear and must be replaced at the first sign of a defect – which in the commercial vehicle sector has to be done very quickly, because every minute of downtime costs money. The new FAG Repair Insert Unit provides distributors and workshops with a solution that extends service intervals and operating times, as well as an efficient OE quality repair that contributes to a reduction in fuel consumption.”