Schaeffler LuK’s Alistair Mason is giving some valuable information on clutch and dual mass flywheel replacements for Vauxhall Vivaros and Movanos, which also covers some Fiats, Mercedes, Nissans and Renaults.

The reason behind this article is that we receive a lot of technical phone calls and warranty enquiries relating to the clutch and dual mass flywheel products on these vehicles and with a little guidance most of these can be eliminated. The first area we need to look at is organising the correct parts, the following information will help the parts supplier identify the correct parts:

- Is the vehicle front or rear wheel drive?

- Date of construction.

- Engine serial number.

We can now focus on the repair, the easiest and advised method of gearbox removal is to remove the front subframe, this gives more space and visibility for a successful clutch and DMF replacement.

Dual mass flywheel replacement

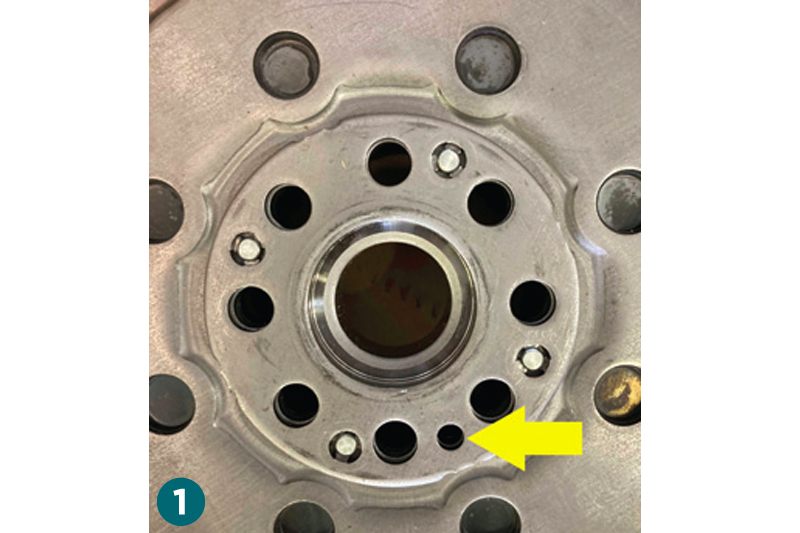

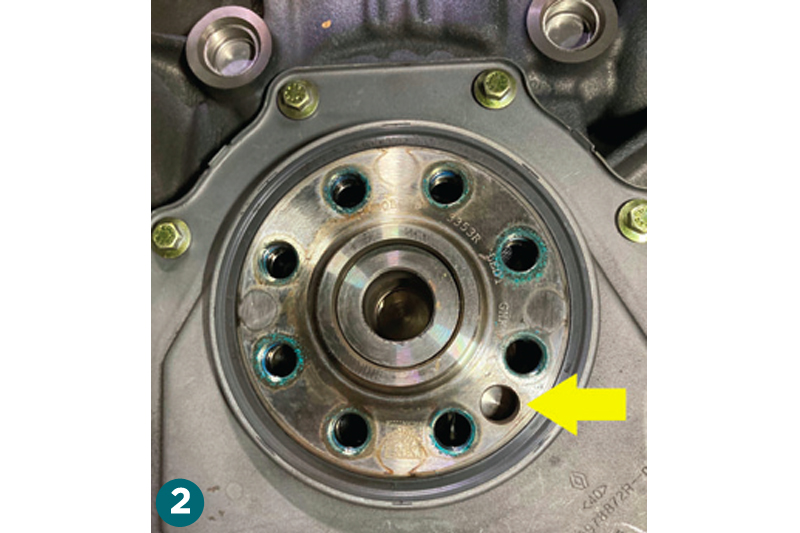

1.6 dCI engine – the flywheel has a timed sensor ring for the engine speed and position sensor, this flywheel can fit in one of eight positions, when fitting the flywheel, the small hole in the centre of the DMF must align with the small drilling in the crank otherwise the vehicle will not start (Figs.1 and 2), this service information is attached to the part on REPXPERT.

The 2.0 variants generally run a solid flywheel. When bolting the DMF to the crank, the bolts must be tightened and torqued in an even and sequential manner, to eliminate the risk of buckle or tilt to the flywheel.

Clutch replacement

Apply a light smear of high melting point grease to the gearbox input shaft and insert the clutch plate, this will ensure the clutch is correct for application and also evenly distribute the grease, remove the clutch plate and remove any excess grease. Always use a clutch alignment tool.

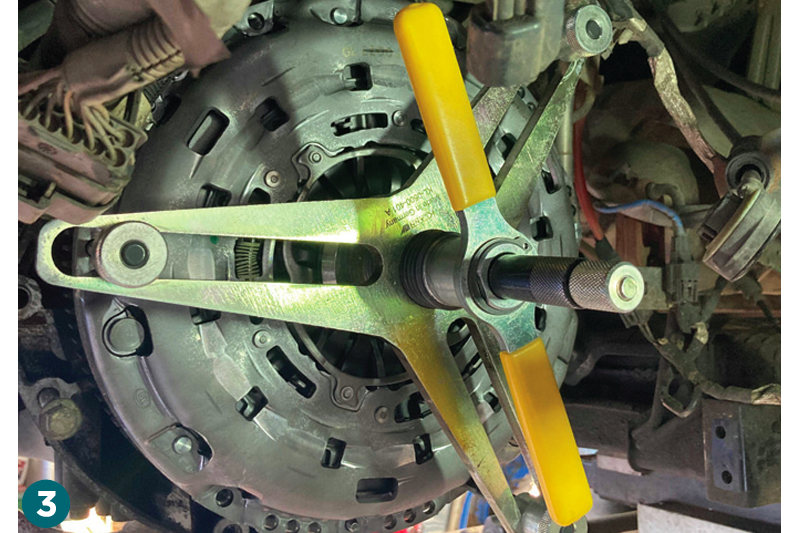

Where the vehicle is fitted with a self-adjusting clutch, always use a self-adjusting clutch tool to eliminate any risk of judder and unintended clutch adjustment, this also removes the risk of stripping threads in the new DMF (Fig.3).

Concentric slave cylinder replacement

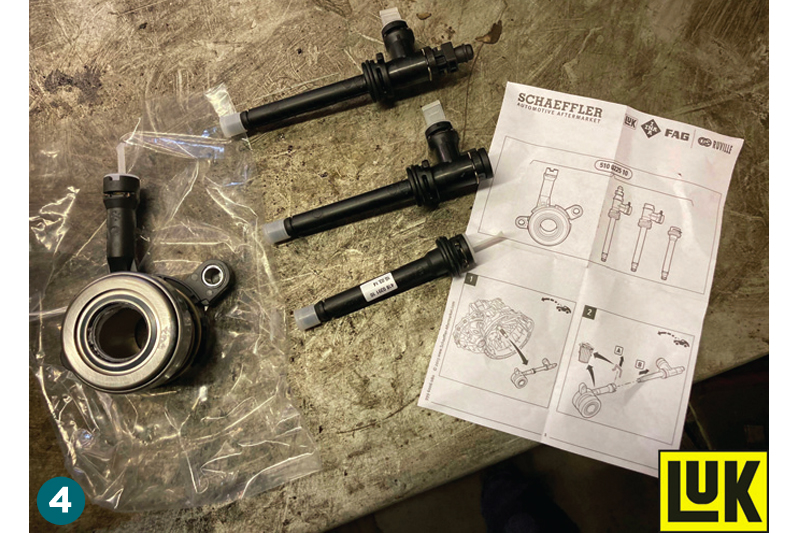

There are generally two variants of CSCs for these vehicles – they have either a two or three bolt fixing CSC. The two bolt fixing CSCs can come with an option of connector pipes and it is very important to select and mount the correct pipe before refitting the gearbox (Fig.4).

These CSCs can be difficult to bleed after replacement, a ‘top tip’ is to prefill the CSC with new and the correct grade of clutch fluid prior to fitment and place a rag over the pipe during gearbox fitment as some fluid will be expelled. Never dry squeeze a new CSC, as this can cause internal damage and always flush the old clutch fluid from the reservoir and master cylinder through the pipe to a drainer, so not to contaminate the new CSC seal.

Gearbox installation

Prior to installing the gearbox, ensure that all the alignment dowels are installed in the gearbox correctly and clean up if required (Fig.5). These can be a tight fit and are known to crush if not fully aligned, this will then lead to misalignment issues that can cause DMF centre bearing failure.

Using a transmission jack, bring the gearbox close to the engine, spend a little time aligning the gearbox to the engine and then ease the gearbox into position and onto the dowels, do not force the gearbox onto the dowels or draw the gearbox on using the bell-housing bolts.

Final checks

When the repair is complete, always carry out a diagnostic check on the engine, any fault on the engine can lead to a premature DMF failure.