Forced induction to maximise engine performance has been a growing trend for VMs for some time, but even though they are now commonplace, turbochargers still represent a challenge to many independents undertaking their service or repair.

For this reason, OE component and systems manufacturer MAHLE is keen to highlight some common causes and effects of turbocharger damage.

Damage to the turbine is one of the primary reasons behind poor turbo performance, or even complete component failure; contamination of some form is generally responsible for this.

© icsnaps/Fotolia.com

Oil or nothing

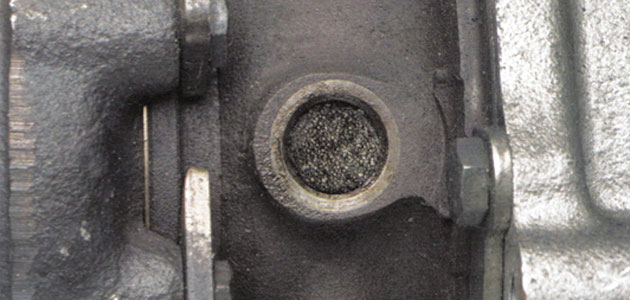

If oil carbon enters the bearing case (Fig 1) it can result in any or all of the following: blue smoke; the loss of engine performance; the loss of engine oil; contamination of the charge-air cooler; a clogged exhaust gas cleaning system; and – with adjustable turbochargers – blocked control mechanisms.

Generally these effects are caused by poor quality engine oil, an overheating turbo or the immediate shut down of a hot engine.

Therefore it is vital to use the correct grade of oil as specified by the VM and let a hot engine run for at least a minute before shutting it down.

Foreign deposits

In addition, technicians must thoroughly clean the oil pan, and flush the oil following turbocharger damage to ensure that no foreign deposits enter the lubrication circuit. You should also pay close attention to the necessary installation instructions and performance measures during engine tuning.

Naturally, observing the VM’s oil change intervals and replacing the filter with an OE replacement is a prerequisite. Oil carbon deposits in the oil pipe can have similar effects to oil carbon found in the bearing case, but can also lead to excessive turbocharger noise and even total turbocharger failure.

The additional causes include an overdue oil change, incorrectly installed oil pipe or missing heat shield. The subsequent remedies include replacing the oil pipe and ensuring its correct installation, or replacing the charge-air cooler and particulate filter if the turbocharger has needed replacement.

Excessive oil consumption is often due to a problem with the oil return pipe which, in common with the aforementioned oil related issues, means that oil can be forced into the turbine and the compressor.

This affects the operation of the internal components and can collect in the charge-air cooler.

Cause for concern

Probable causes include constriction or a bend in the oil return pipe, the use of sealing compound rather than a gasket set, the failure to replace the engine connection when replacing the return pipe, or even simply too much oil in the engine.

Technicians therefore need to ensure that the return pipe is thoroughly cleaned if it is to be re-used and, whether reinstalled or replaced, a new gasket set must be used. In addition, the turbo must be replaced if any of its internal components (VTG, by-pass, wastegate etc.) have become stiff.