Providing a safe working environment for operators is essential, especially when using pneumatic tools and compressed air. Chicago Pneumatic explains.

If there is a failure in the air network and the hose is not adequately clamped, the resulting whiplash could be devastating. Failure to follow best practice can result in injuries, associated production downtime and decreased productivity.

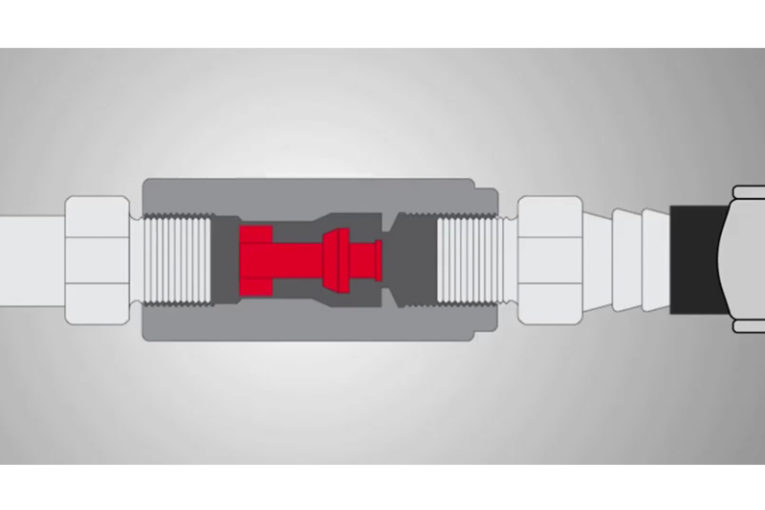

In this video Annabelle Bray, Accessories Product Manager at Chicago Pneumatic, demonstrates how to fit an air fuse to an air line set-up in just a few seconds, and gives advice to increase safety in the workplace and protect workers from potential hose whiplash.

“ Adding an air fuse to your air line set-up will prevent you from hose whiplash. Select the air fuse according to your tool maximum air consumption. ” Annabelle Bray, Accessories Product Manager at Chicago Pneumatic

For more information, click here.