A full timing belt replacement guide for a 2005 Kia Picanto 1.1 petrol from the experts at Schaeffler Automotive Aftermarket.

This month, Schaeffler’s Alistair Mason replaced the timing belt on a 2005 Kia Picanto 1.1 (petrol) – the popular ‘city car’, which was first launched in 2004 by the South Korean manufacturer and is now on its third generation.

On this occasion, the engine was identified as an ‘interference engine’, so in the event of timing belt failure, consequential engine damage is likely. Adjustment work on the toothed belt must always be carried out at an ambient temperature and always rotate the engine in the direction of rotation.

Step-by-step process

With the vehicle placed on the ramp, open the bonnet and raise the car, then remove the O/S/F wheel and O/S splash guard (See below) – fit an engine support too.

Lower the vehicle and disconnect the coolant expansion tank, power steering reservoir and washer bottle filler (See below).

This now provides free access to the engine mounting, which can now be removed, allowing entry to the auxiliary belt area (See below).

First, slacken the water pump pulley bolts, loosen the alternator clamp bolts, remove the tension from the auxiliary belt and remove the belt for inspection of wear and/or damage. It is always best practice to replace the auxiliary belt when replacing the timing belt, as some belts now have a service life and recommended change interval. Next, remove the water pump pulley and the upper timing belt cover.

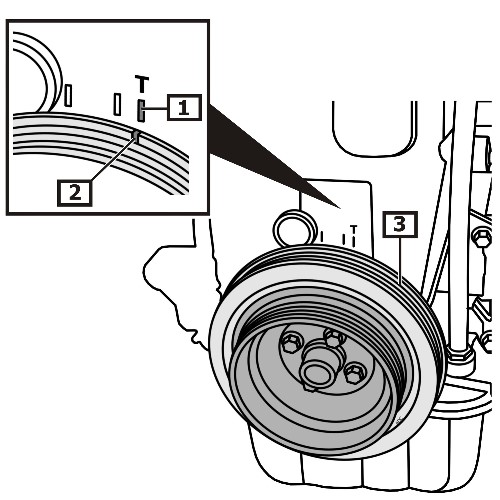

Rotate the crankshaft pulley in a clockwise direction until the crankshaft and camshaft timing marks align (See below).

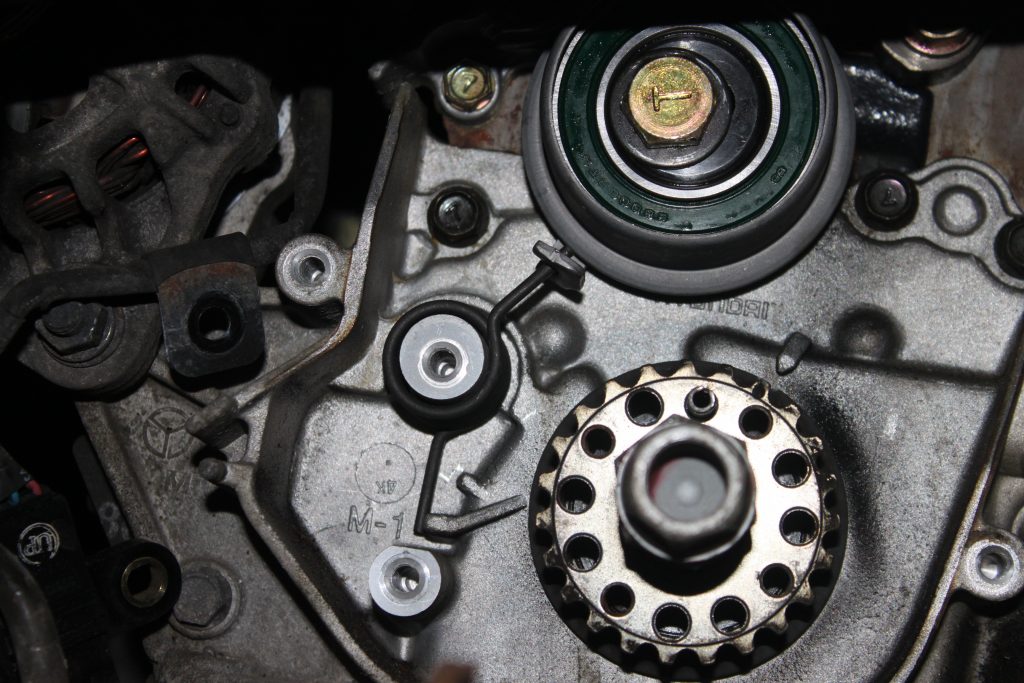

Subsequently, remove the four crankshaft pulley retaining bolts pulley washer and outer crankshaft pulley. Next, remove the crankshaft pulley centre bolt, washer and then the inner crankshaft pulley (See below).

The lower timing belt cover can now be removed, along with the crankshaft position sensor ring and sensor. Now, slacken the tensioner centre bolt, ease the tensioning roller back – the timing belt can now be relieved of its tension – then retighten the tensioner centre bolt. The timing belt can now be removed.

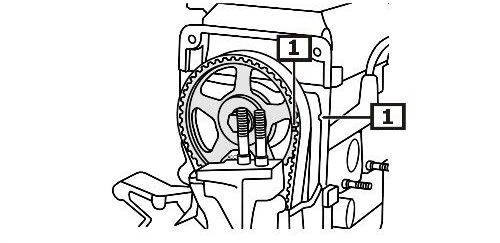

Remove the tensioning roller and inspect the timing belt area for any oil or coolant leaks that could contaminate the new belt and rectify if required. Ensure the timing belt area is clean and then fit the new tensioning roller, confirming it has fitted onto the tensioning spring (See below) and is pulled back against its stop. The timing belt can now be installed.

Confirm the timing marks are still aligned, then fit the timing belt to the crankshaft pulley – working in an anti-clockwise direction – then wrap around the tensioning roller. Slacken the tensioning roller and allow the spring to ‘self- tension’ the belt and roller before tightening the tensioning roller centre bolt.

Again, ensuring the timing marks are still aligned, rotate the crankshaft two complete revolutions, and slacken the tensioner roller centre bolt. Adjust tension, if required, and then retighten and torque to the manufacturer’s specification.

Now, torqueing the bolts as required to the manufacturer’s specification, re-fit all parts in reverse order of removal.