Steve Smith at Pico technology looks at adding an extra level to your diagnostic process with parasitic drain testing.

Customer complaints surrounding flat batteries are common throughout the year, peaking during the winter season. When a customer comes in complaining that their vehicle fails to start after standing for a couple of days, the parasitic drain alarm bells should start ringing.

Battery evaluation is normally taken care of using automated devices – or better still, the PicoDiagnostics battery test procedure where we test not only the battery, but the starting and charging system in one hit. Once the above are confirmed, we must then focus our attention on battery drain and parasitic current draw.

This test is often overlooked, yet should conclude any customer complaints surrounding non-starts as a result of a discharged battery. Parasitic drain demands a prolonged test (30 minutes is not uncommon for a modern vehicle to shut down and move to sleep mode). For those vehicles with a history of battery discharge, you may choose to monitor the parasitic drain overnight or even a number of days. This presents a challenge surrounding current clamps.

Pico current clamps are powered via an internal battery with a continuous operational time, ranging from 14 to 16 hours. We run the risk of erroneous results during prolonged parasitic tests (not to mention the time the customer’s car is off the road).

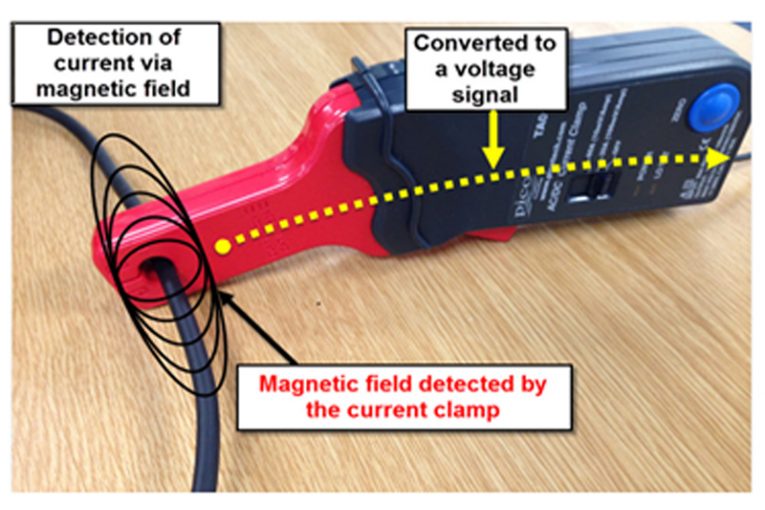

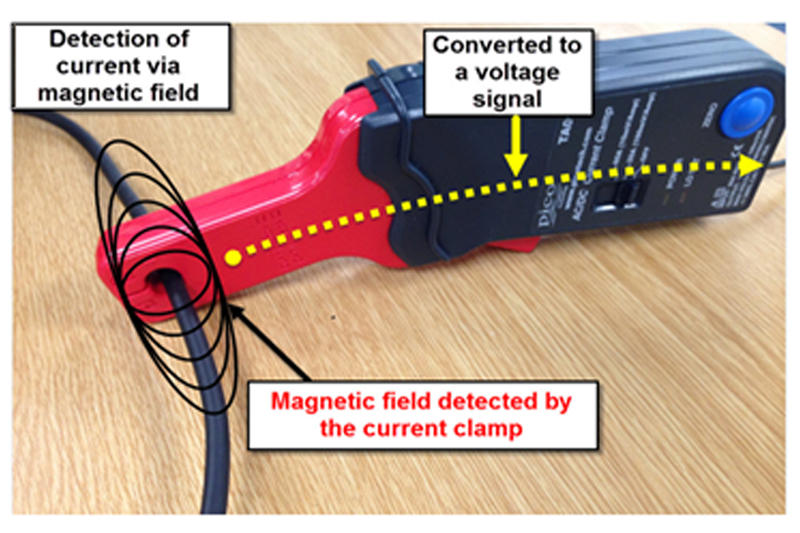

I also think it is worth mentioning here how a current clamp operates in relation to the values we capture on our scope screen.

As current flows through a conductor, a magnetic field is produced about the conductor. By closing the jaws of our current clamp around the conductor, the magnetic field can be detected and converted into a voltage directly proportional to the strength of the magnetic field. The voltage is then sent to the scope and displayed on-screen as a current value. Prior to connecting the clamp around the conductor, a zero operation is carried out to ensure accurate display of current values and a true zero point reference. This is achieved by pressing the zero button on the clamp.

Whilst we confidently set our current clamp to zero before taking any measurement, prolonged measurements will highlight drift in the form of our readings drifting away from the actual value.

Any measurements taken are only as valid as the accuracy of the equipment used and so being aware of the following tips will reduce the impact on our results associated with drift.

Temperature and environmental conditions are the biggest offenders when we refer to drift. Acclimatise your clamp to the test environment.

1. Ensure the clamp is used away from sources of environmental noise.

2. Be aware of the minimum operating temperatures of the current clamp (0°C).

3. Ensure the clamp’s internal battery is prepared for overnight testing. This may require a new battery.

4. Switch on the current clamp and allow the device to warm up (approx. 10 minutes).

5. Ensure correct orientation of the clamp (refer to arrow on clamp jaws which indicates direction of current flow).

6. Ensure the vehicle is locked and all keys are out of the detection range of any Keyless/SMART entry systems. Customer keys within the detection range of the vehicle will prevent total shutdown of the vehicle network.

7. Using the zero function of the clamp is essential for accurate measurements. However, for overnight testing you may opt for the technique below.

The principle of zeroing the current clamp relies upon the charging of a capacitor to remove any DC offset value. The capacitor has the potential to discharge overnight (rates vary between clamps), resulting in drift away from the actual measurement value. An option here with PicoScope is to switch on your current clamp and wait for the 10 minute internal warm up to elapse (do not zero the current clamp).

Connect the clamp to your PicoScope and select the relevant probe setting (60A Current clamp [20A Mode]) from the Channel options menu. Select the relevant input range, which will depend on the style of vehicle. ±1A will cover you for the majority of measurements once the vehicle has completed the door locking/security phase.

With the waveform on screen you will notice the current value is not at zero amps as we have not zeroed the clamp. Here we can use the PicoScope software to carry out a zero offset procedure by clicking on the Channel options button and selecting Zero Offset. PicoScope will now ask you to short the BNC terminals of your chosen channel together (this would normally be a x1 test lead).

At this point select OK inside the Zero Offset dialog box and the scope will now adjust the output value of your current clamp to zero. Here we achieved an alternative to using the zero function of the current clamp, therefore bypassing the capacitor discharge issue.

Remember, after completion of your overnight testing, select the Channel options button and click on the Clear button from the Zero Offset menu, restoring your scope channel to factory setting.

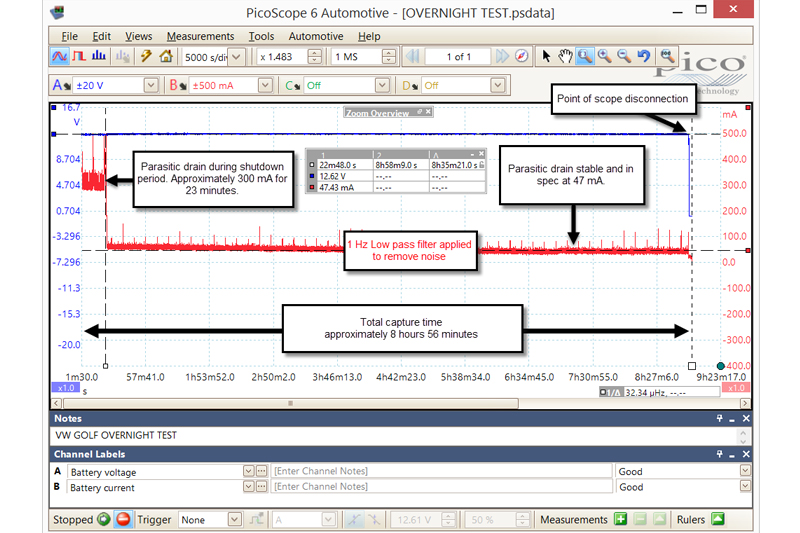

With your clamp prepared, you can now connect around the battery lead to commence overnight monitoring of the vehicle parasitic drain. In Fig 1 we can see the shutdown period of the vehicle where the parasitic drain was out of specification for over 23 minutes (typical for modern vehicles).

The final parasitic drain confirmed the vehicle to be in specification sleep mode for over eight hours at 47mA (80mA being the arguable recommend maximum value).

When monitoring parasitic drain, we are only looking for the average of very low current values (below 80mA). Such low values are always susceptible to noise and so you will find that low pass filtering will be essential to measure the average value of concern. Periodic spikes visible during parasitic drain measurements are often attributed to security LED operation or keyless entry systems looking for the vehicle keyset.

Whilst they are visible, they tend to pulse at very rapid intervals (high frequencies) and when averaging out the peak values of these pulsations, they have a negligible contribution to parasitic drain. Such pulsations will eventually halt as part of deep sleep mode built in by manufacturers to protect the vehicle battery during prolonged periods of inactivity.

In conclusion, parasitic drain testing cannot be ignored and must conclude our test procedure when investigating complaints surrounding flat batteries. Whilst the procedure will extend the diagnostic time involved, it will most certainly pay dividends to the customer and the technician.